|

Joshua Bigwood & Son

Limited

|

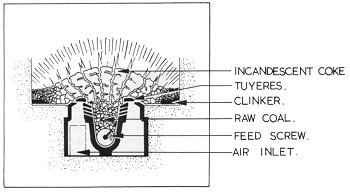

An underfeed stoker, located beneath the

fire.

|

Underfeed stokers are a British

invention which was used as early as 1838. It is an ideal way of

firing bituminous coal in a small automatically controlled unit.

The stokers have been used for such diverse purposes as the

firing of central heating boilers, steam boilers, kilns and

almost every type of industrial furnace. They provide an

efficient way of firing which uses the minimum amount of fuel

and requires less labour than traditional methods. |

|

Bigwoods offered a range of underfeed

stokers for various types of boilers. There was the 'Unicalor'

stoker and the 'Unidrive' stoker.

In the 1980s both models were replaced with

the Bigwood angle feed stoker. This was basically a bunker to

boiler stoker but with the pick up screw capable of being angled

through 180 degrees. In the 1960s Bigwoods were the largest

underfeed stoker manufacturers in the country, with an annual

production in excess of 600.

In addition, Bigwoods made screw elevators,

turf burners for burning peat and trickle feeders for the top

firing of brick kilns.

Unicalor coal stokers |

|

The ‘Unicalor’ stoker was available as

a bunker to boiler model. A screw inserted in the base of a coal

bunker brought the coal forward to a transfer box, where a second

screw collected the coal and delivered it to a retort set in the

base of the boiler, where combustion took place. The stoker was

available for coal feed rates of 220 to 750lb. per hour for firing

tubular flue boilers. A similar design, suitable for installing in

cast iron sectional and vertical steam boilers was available for the

full range of 20 to 750lb. per hour.

The ‘Unicalor’ stoker was also available as a hopper model,

which had a hopper for the coal situated over the transfer

screw.

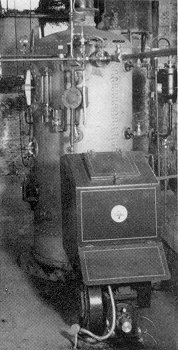

The photograph shows a Bigwood Unicalor

screw type standard hopper stoker, applied to a small vertical

boiler. |

|

The Unicalor bunker-feed

stoker |

|

|

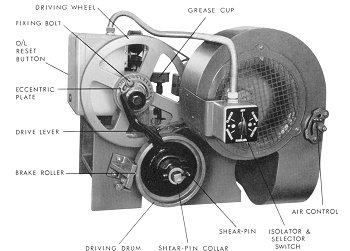

The Unicalor Drive

|

A 'V' belt drive transmits the drive from a totally

enclosed electric motor to a worm reduction gear, from which the

final reduction is obtained through an adjustable pawl and ratchet

mechanism. This gives the choice of a range of feeds by adjustment

of the selector plate or mask. All parts were interchangeable and a

slipping clutch protected the mechanism from an overload. The gears

were contained in an oil bath. |

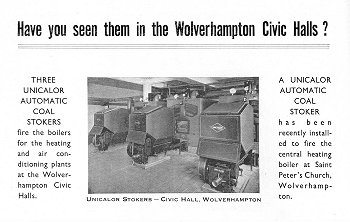

| This is part of a Bigwood's

advertisement that appeared in the programme of the St. Peter's

Church Bazaar of 1938, which was held in the Civic Hall.

It shows Unicalor stokers in the then new

Civic Hall and refers to another recent installation in St.

Peter's itself. |

|

|

Unidrive coal

stokers

After World War 2 Bigwoods offered a lower priced

‘Unidrive’ range of bunker to boiler and hopper models. |

|

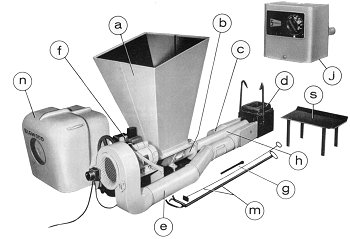

A Bigwood Underfeed Unidrive Hopper Coal

Stoker

|

Parts:

a. Hopper

b. Hopper base

c. Cleanout duct

d. Retort

e. Air duct

f. Drive unit and

control gear

g. Spanner

h. Coal tube (first

section)

j. Thermostat

m. Clinker tongs and

dust rake

n. Cover

s. Clinker tray |

The coal is fed by means of a screw into the base

of the retort, from where it rises into the combustion zone. The

retort is surmounted by a row of tuyeres through which air is

introduced. The fuel and air move together vertically upwards to

produce efficient combustion. The fuel and air flow are

automatically controlled to suit the requirements of each

individual installation. |

|

An underfeed stoker shown during fire

cleaning. |

|

A bank of Bigwood Unidrive

Hopper Coal Stokers in operation. |

The stoker was supplied with

everything that was necessary for the installation, including

fireclay, firebricks, sealing cement and electrical cable and

fittings. The coal feed into the boiler is adjustable in

multiples of 20lbs per hour and there is a fire kindling control

that can be set to operate for several minutes every hour. The

stoker also has a thermostat and a fan to control the fire.

|

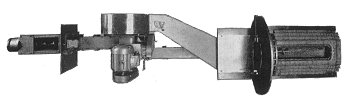

| A close-up view of the air

duct and the driving wheel at the back of the stoker. |

|

|

A Bigwood drawing of the

arrangement for converting a Lancashire boiler into single flue, five

pass working, which increased the boiler efficiency but reduced the

output to 60% of the original rating. |

| We would like to thank David Evans for his help

in producing this page. |

|

Return to

the

Bigwood section |

|