|

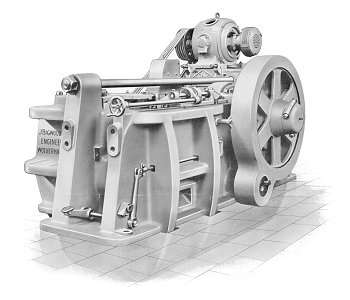

Joshua Bigwood & Son

Limited

|

High Efficiency

Precision Forging Machine

The Bigwood High

Efficiency Precision Forging Machine was designed to produce an

endless variety of close tolerance forgings that were extremely

accurate, so accurate in fact that machining was not necessary. The

machine was much more versatile than the usual Upsetting type of

forging machine, due to the exceptionally large die space and

gathering capacity. The dies were easily accessible to reduce the

time necessary for changing and setting up the tools. The machine

was equally at home on a mass production line or when only a few

forgings of one size were required. |

|

|

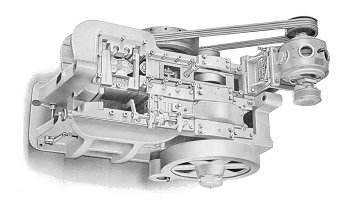

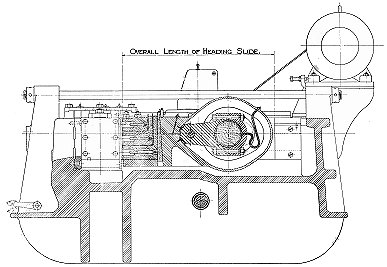

The long hanging heading slide moved on narrow

guides to ensure a straight line movement and accurate

registration of the dies. The die slide was operated from a

single cam on the crankshaft and via a double toggle joint

mechanism to provide an extremely powerful and precise gripping

action over the whole length of the dies.

An automatic stock gauge between the dies and heading tools

could be adjusted by hand to enable the operator to gauge

exactly the amount of material that was required for a given

forging. |

| Several safety devices were fitted including a

brake at the end of the camshaft which held the crank securely

in its neutral position. The balanced flywheel was of the

safety-slip type which safeguarded the machine in case of

overload. A safety trip was fitted to the operating gear and a

safety device was fitted to the die slide closing mechanism. |

|

The long hanging head slide prevented any

misalignment of the heading tools. |

Specification

Capacity up to 2 inches diameter

9 inch stroke

55 strokes per minute

6.25 inch gather

3.75 inch die opening

Flywheel rotated at 220r.p.m.

Flywheel diameter - 3ft. 4in.

Power - 18h.p. |

| The company also produced a range of machinery for the

forging industry, including power hammers, plain and automatic drop

stamps, bulldozers, forging rolls, and hot saw and burring machines. |

|

Return to

the

Bigwood section |

|