|

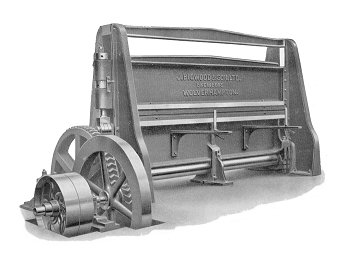

The press type corrugating machine

|

The press type corrugating

machine was particularly useful where it was desired to

produce different types of corrugation. It used inexpensive dies

which could be quickly changed and easily machined when worn.

The construction of the machine was substantially constructed

and could be driven from a belt or motor.

The sheets could be up to 12 feet long. The power required to

drive the machine at its maximum capacity was 12hp. |