|

Joshua Bigwood & Son

Limited

|

Straightening

Machines

Bigwoods designed and

constructed plate straightening machines for many years. The

machines were grouped into two categories. The first was for dealing

with plates or sheets up to three sixteenths of an inch thick. These

machines were usually equipped with thirteen or seventeen

straightening rolls. The second category was for machines dealing

with greater thicknesses. These were usually provided with seven or

nine straightening rolls. The largest of the machines could deal

with plates up to 2.5 inches thick and any width. |

|

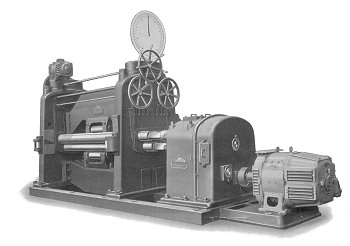

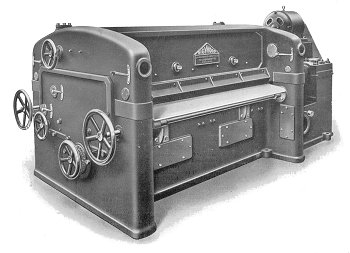

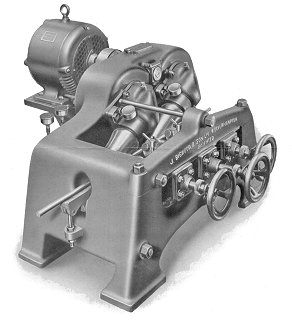

A plate straightening

machine for dealing with thick plates

|

The bearings on both the straightening and

supporting rollers had water cooled bearings and the top rolls

were operated by an electric motor which was push-button

controlled. Precision hand adjustment was provided for the inlet

and outlet rollers and the degree of adjustment was precisely

registered on a large dial. The drive from the motor was via a

totally enclosed, self-lubricating gearbox and other bearings

were equipped with a pressure grease system. The strong

construction was reinforced with steel tie rods. |

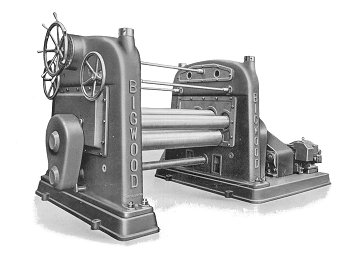

| In the smaller machines the straightening rollers

have an extra large diameter to avoid any undue deflection when

straightening thin and narrower plates. The rollers were driven

from a simple, reliable gear drive and were easily and

accurately adjusted using a graduated indicator dial. The use of

a gear drive with double helical teeth ensured smooth and

vibration-less running. |

A smaller plate straightening machine

|

|

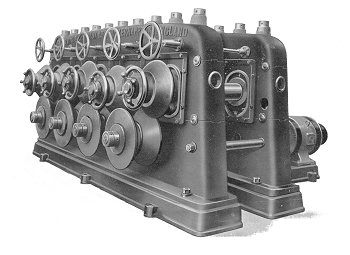

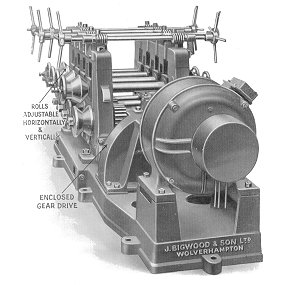

The S.M.16 shape and section straightening

machine with 9 rolls.

|

The shape and section straightening machine was

designed to straighten large quantities of bars in a large-scale

production system. The top rollers were vertically adjustable to

deflect the material to be straightened and horizontally

adjustable to enable complicated sections to be dealt with. Each

machine was supplied with a set of rollers to suit the

customer's own requirements and all gearing was of cast steel

and all bearings had bronze bushes. The speed of straightening

depended upon the shape of the section and the nature of the

material. |

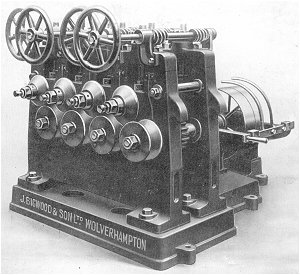

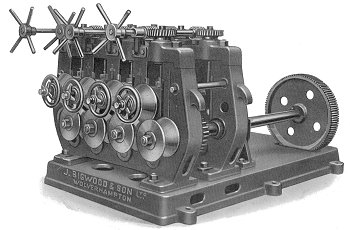

| The S.G.5 shape and section

straightening machine with 8 rolls. |

|

|

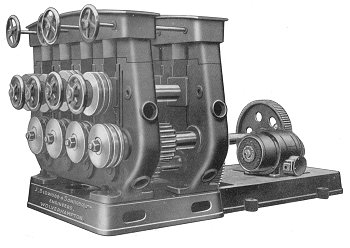

The S.H.8 shape and section

straightening machine with 8 rolls. |

| The S.K.10 shape and section

straightening machine with 8 rolls. |

|

|

A motor-driven S.H.8. |

| The Bigwood high efficiency multiple roller sheet

straightening machine could perfectly flatten buckled and dished

sheets and remove all rolling and stretcher strains. The machine

was easily adjustable using the hand wheels on the front of the

machine, each of which was provided with an indicator.

Lubrication was centrally provided by a pressure grease system

and finger guards were provided to safeguard the operator. |

A high efficiency 17 roll sheet

straightening machine

|

|

No. OA tube and bar straightening machine

|

The No. OA tube and bar

straightening machine could straighten any bar up to seven

eights of an inch diameter and any tube up to one inch in

diameter at a speed of 300 feet per minute. The rollers were

adjustable both horizontally, vertically and in an angular

direction to ensure that alloy heat treated steels could be

straightened in a perfect manner. All bearings were covered to

prevent the entry of dirt and a special flood lubrication system

and oil bath was included. The machine could be driven from a

belt or electric motor. 7 hp. was required for dealing with

tubes and 10 hp. for bars.

|

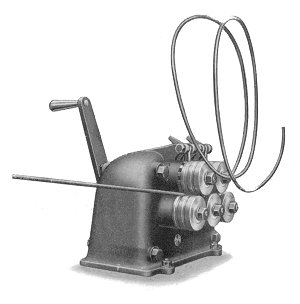

| A hand operated

straightening machine. |

|

| The following four photographs were kindly sent by

Terry Pringle. They show a working M.R.L. 4 plate

levelling machine that is still in use. As can be seen,

it is a typical heavy-duty, well-built Bigwood product,

designed to have a long and reliable life. It is lovely

to see a well looked-after Bigwood machine, still doing

what it was designed to do. Sadly the business closed

in the middle of 2022 and the machinery was auctioned

off. Unfortunately no one was interested in buying the

machine, so it will now be scrapped.

I must thank Terry for his excellent photos and

details of the machine's sad demise. |

|

Return to

the

Bigwood section |

|