From the cover of the 1958. Traughber Filter

brochure. Courtesy of Paul Nightingale.

The introduction from the Traughber Filter

brochure. Courtesy of Paul Nightingale.

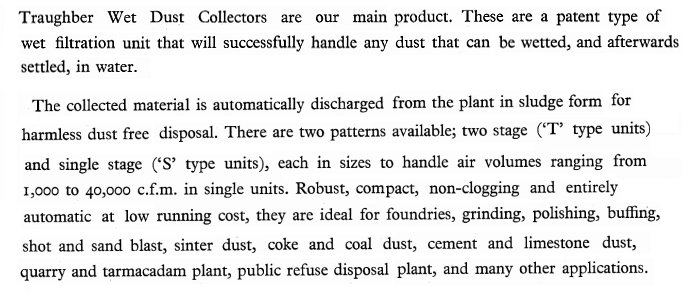

Traughber wet dust collectors. From the

brochure, courtesy of Paul Nightingale.

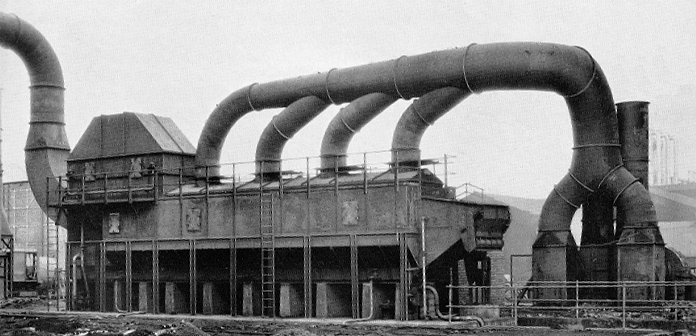

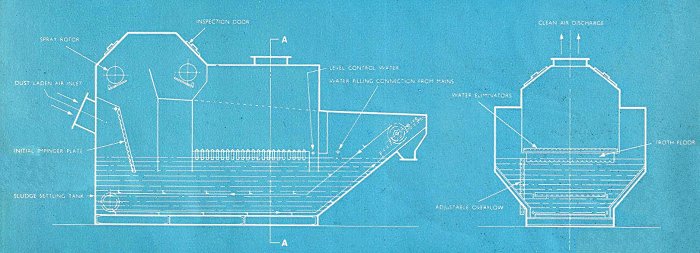

A 40,000 c.f.m. 'T' type filter handling

sinter dust at a steelworks. Courtesy of Paul Nightingale.

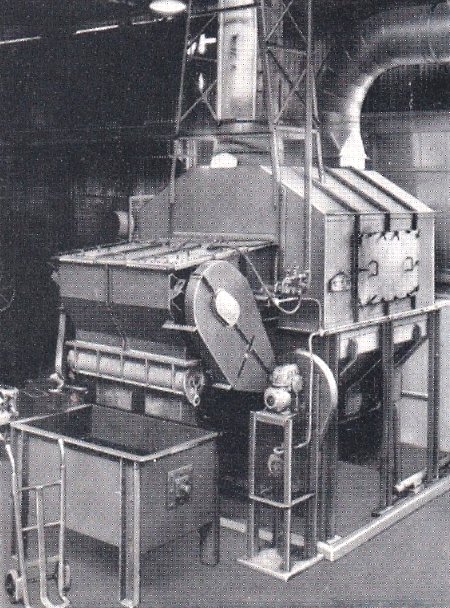

An 'S' type filter handling 10,000 c.f.m. of

air. Courtesy of Paul Nightingale.

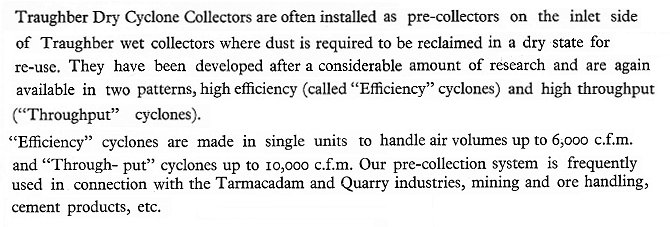

Dry Cyclone collectors. From the brochure,

courtesy of Paul Nightingale.

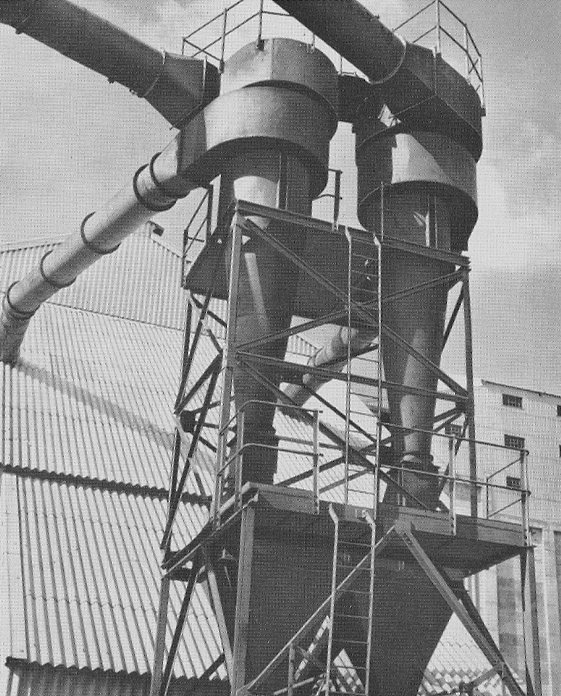

Twin 'Throughput' Cyclones, each handling

10,000 c.f.m. of air. Courtesy of Paul Nightingale.

Troughber 'T' type filters. From the brochure,

courtesy of Paul Nightingale.

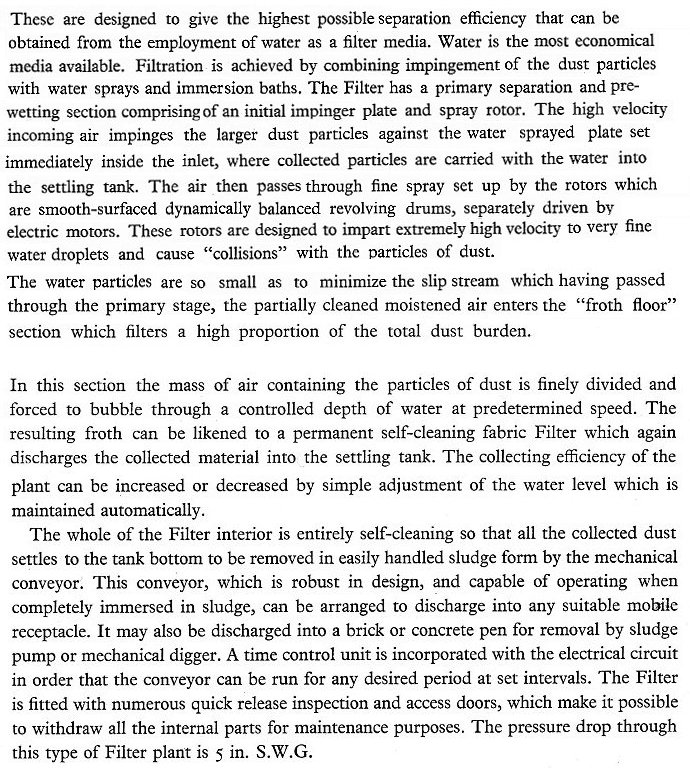

A diagram of a Troughber 'T' type filter. From

the brochure, courtesy of Paul Nightingale.

A 9,000 c.f.m. 'T' type filter, handling

crushed slag dust. Courtesy of Paul Nightingale.

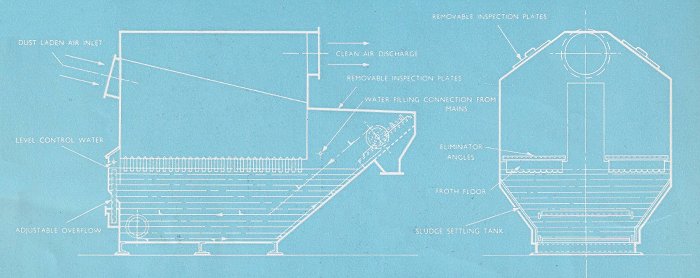

A diagram of a Troughber 'S' type filter. From

the brochure, courtesy of Paul Nightingale.

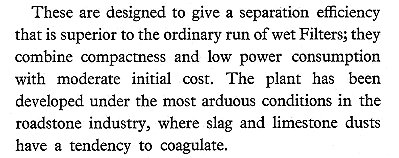

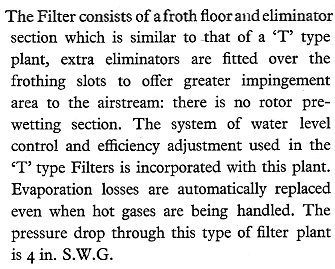

Troughber 'S' type filters. From the brochure,

courtesy of Paul Nightingale.

|

|

|

|

Troughber 'S' type filters. From the

brochure. Courtesy of Paul Nightingale. |

A 5,000 c.f.m.

capacity plant handling limestone dust. Initial

separation is by a 'Throughput' Cyclone and secondary

collection by an 'S' type filter. Courtesy of Paul Nightingale. |

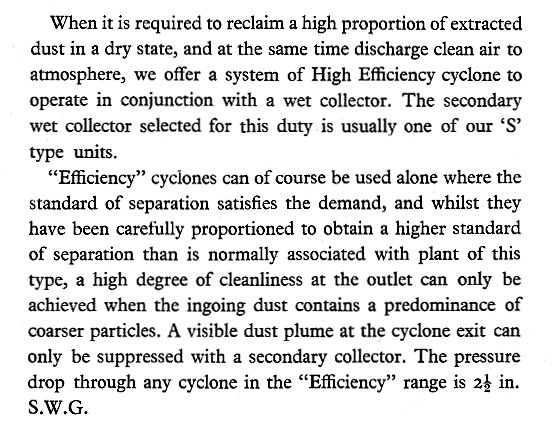

Troughber 'Efficiency' cyclones. From the

brochure. Courtesy of Paul Nightingale.

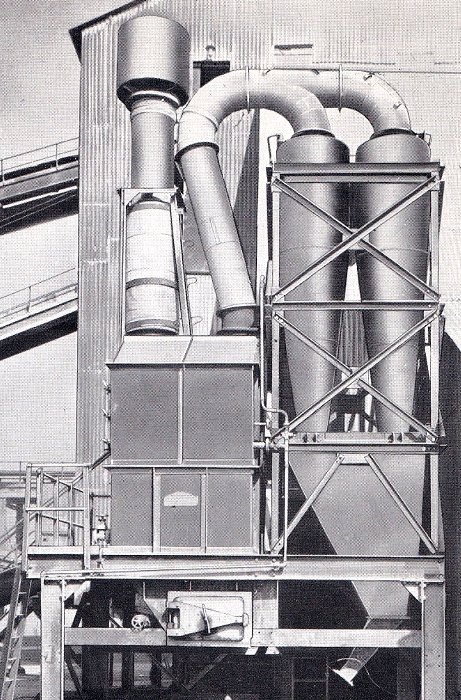

| Twin 'Efficiency' cyclone

pre-collectors, each handling 2,250 c.f.m. of gases at

150 degrees centigrade, with a slag dust admixture.

An 'S' type filter with

overhead sludge discharge is fitted as a secondary

collector.

From the brochure. Courtesy of

Paul Nightingale. |

|

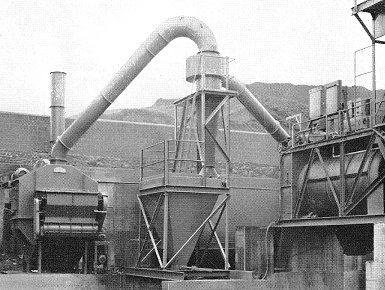

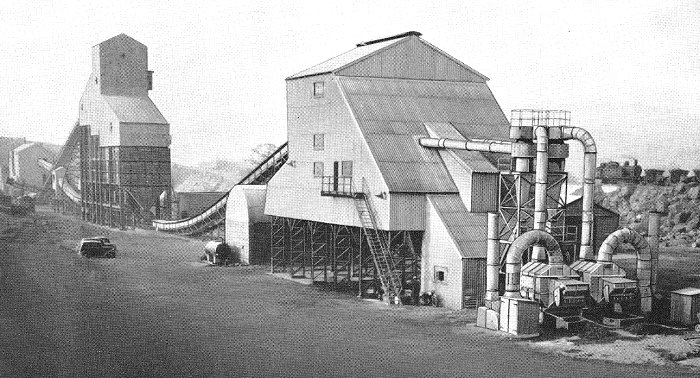

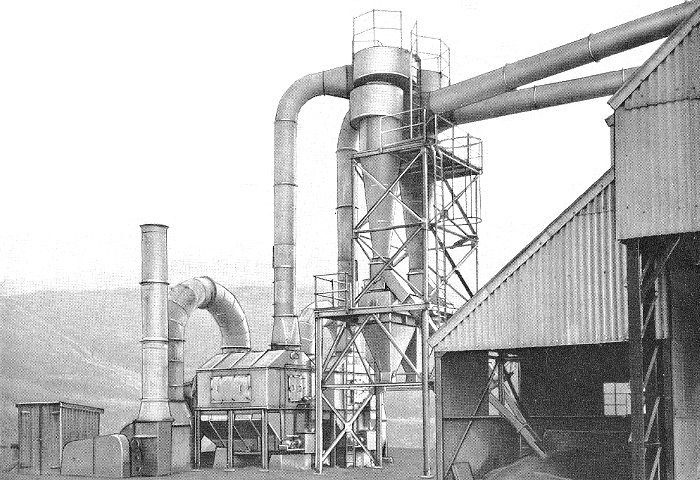

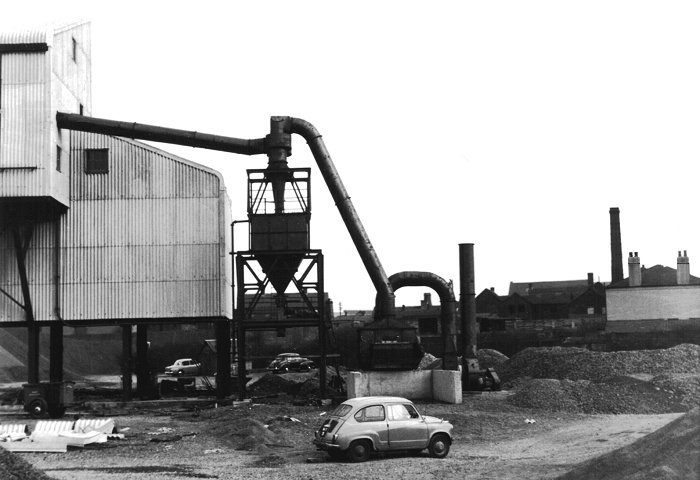

A general view of a Traughber

extraction plant exhausting from a Tarmacadam Coating

and Mixing plant. Another Troughber installation at

these works is handling dust drawn from the secondary

crusher plant. From the brochure. Courtesy of Paul

Nightingale. |

Filtration efficiency. From the brochure.

Courtesy of Paul Nightingale.

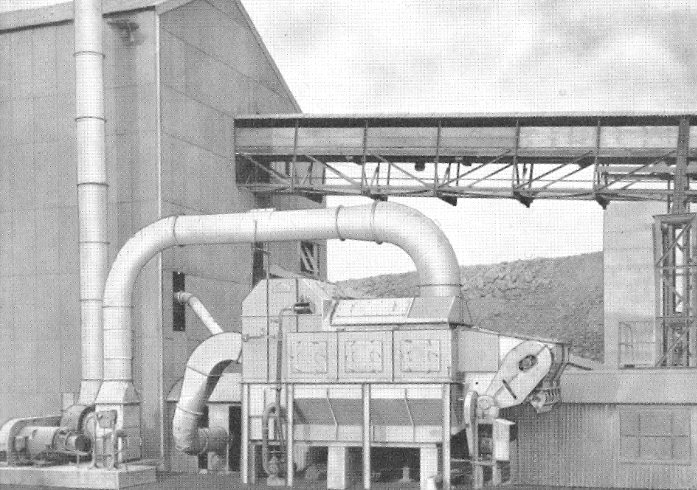

Twin 'Throughput' cyclone

pre-collectors with 'S' type filter units. Each plant is

handling 10,000 c.f.m. of gases at 135 degrees

centigrade. The collected slag dust is discharged

through gravity chutes into a ground filler hopper. From

the brochure. Courtesy of Paul Nightingale. |

|

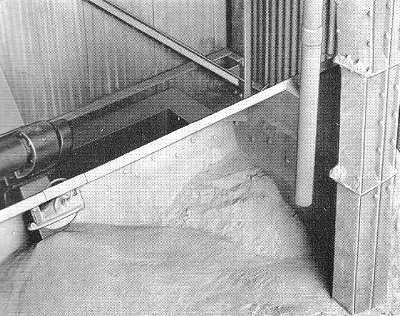

A close-up view of a ground

filler hopper. From the

brochure.

Courtesy of Paul Nightingale. |

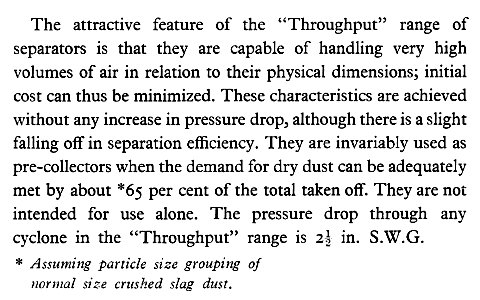

| The 'Throughput' range of

separators. From the

brochure.

Courtesy of Paul Nightingale. |

|

|

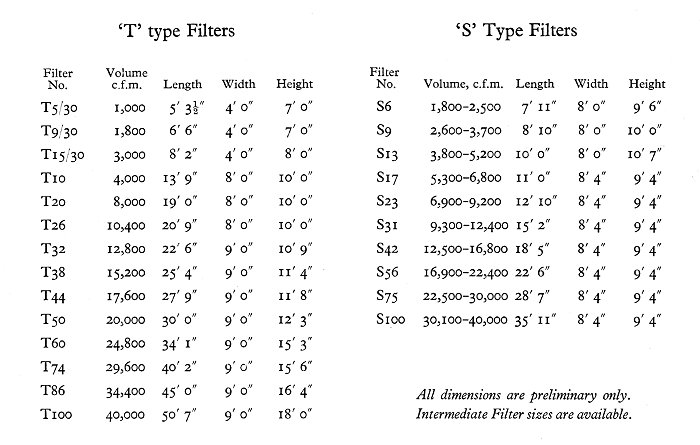

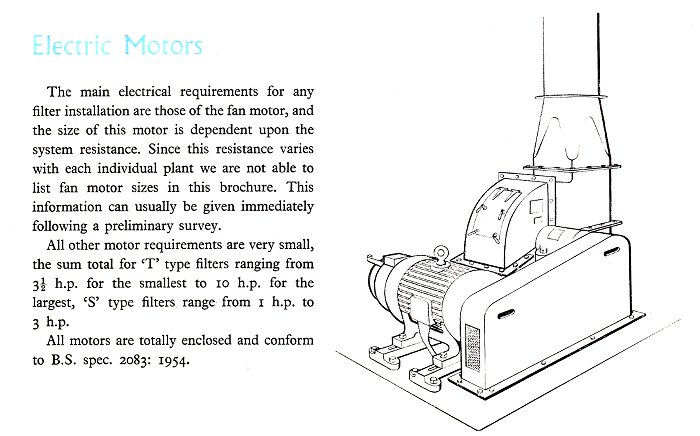

From the brochure. Courtesy of

Paul Nightingale. |

|

From the brochure. Courtesy of

Paul Nightingale. |

From the brochure. Courtesy of Paul

Nightingale.

From the brochure. Courtesy of Paul

Nightingale.

A photo at an unknown site with Troughber dust

extraction equipment. Courtesy of Paul Nightingale.