The Bigwood

Pipe-Bending Machine

Many people criticise Britain’s ailing

industries, especially in these post Thatcherite days when

engineering has sadly become so unfashionable. Not that many

years ago Great Britain was at the forefront of many

technologies and this is often forgotten. What follows is an

example of just how good we were at developing cutting-edge

technology. Even if we no longer have the will, or inclination

to invest and build new factories in which to use our innovative

technology, others still do. This is the story of an important

machine that was built in Wednesfield between 1979 and 1981,

which is now surplus to our country’s industrial requirements.

The machine has found a new home in Canada where it will

hopefully have a long and productive future. Background

In 1980 Bigwoods in collaboration with Radyne Ltd and the

Babcock organisation, built one of the world’s largest induction

pipe-bending machines. It was built under contract to the

consortium of the British Steel Corporation and Vickers U.K.

This machine ended its U.K. life in Scotland and has recently

been transported to Canada to be re-assembled as one North

America’s most important large pipe-bending facilities. |

|

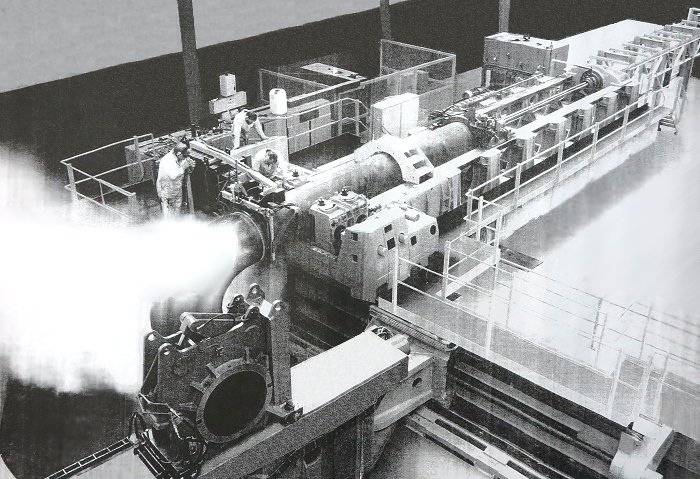

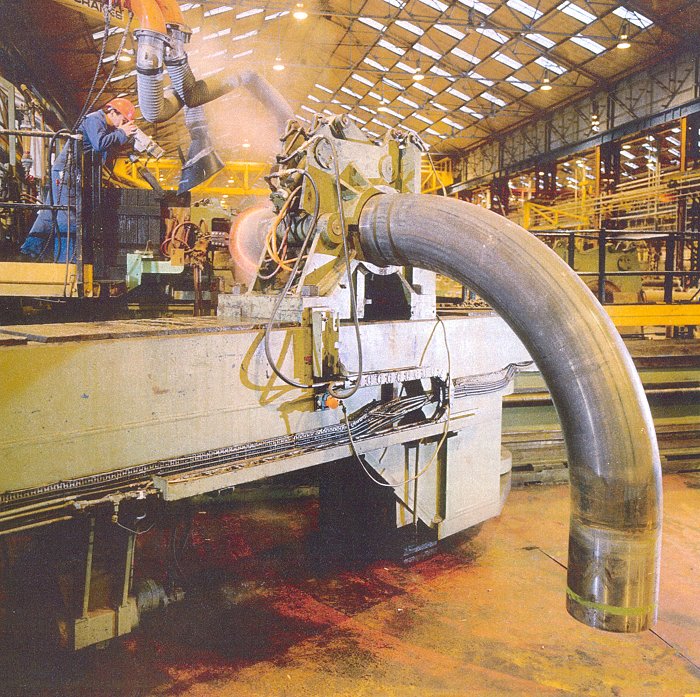

The pipe-bending machine in operation. |

| A Brief History

In the 1980s the Romeo Vickers consortium

were developing nuclear power stations and equipment for Trident

submarines. For part of the work they required a large

pipe-bending machine and so a joint venture was set up between

Romeo Vickers and the British Steel Corporation at Tipton to

develop a suitable machine for the purpose. The design and

building work for the machine was contracted out to four

companies by the project managers at B.S.C. as follows:

Babcock Power Limited, Research Centre,

Renfrew carried out design and development work.

Bigwood & Company of Wolverhampton carried

out the mechanical, structural and hydraulic work and did the

final assembly.

Lightwood Engineering produced the

electrical layout.

Radyne of Wokingham, Berks designed and

built the necessary electronic control equipment. |

|

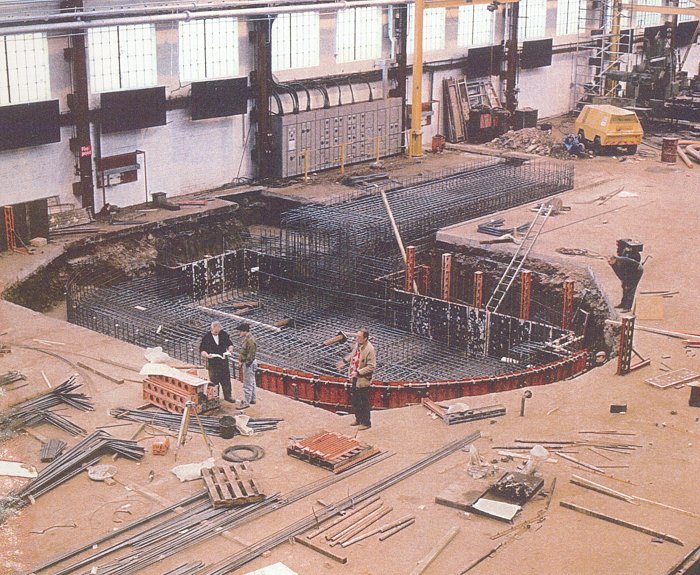

Preparing the site, in readiness for

the installation of the machine. |

| The machine has an impressive specification. It is

capable of bending a 36 inch diameter pipe with 4 inch thick

walls and can equally handle a 6 inch diameter pipe with quarter

inch walls. The machine includes an induction heater to heat the

pipe and a water and air cooling system to cool the pipe after

bending. The temperature is accurately controlled and the water

system filters and recycles the water for reuse. There is a

triple axis movement of the rolls and coils, with forward,

backward, up and down control of the pipe and independent

adjustment of the heating coils. A 65 ton hydraulic ram with a

30 foot stroke transports the pipe through the machine at speeds

from 38mm per minute for large bore heavy wall pipe to about

250mm per minute for small bore light wall pipe. |

|

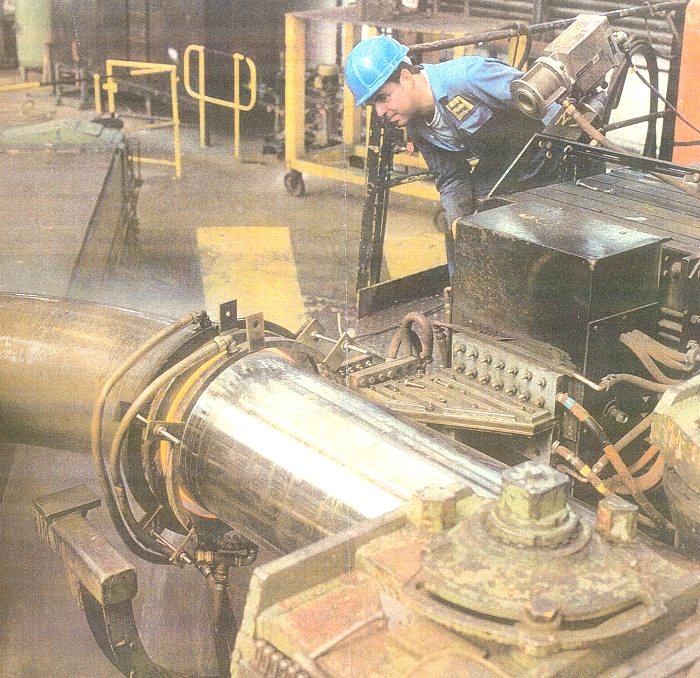

An operator keeps an eagle-eye on a large

bend. |

|

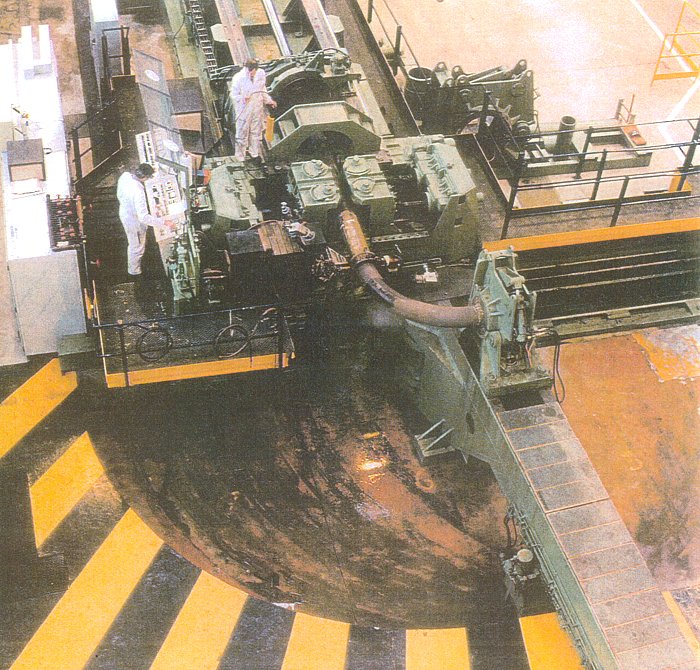

An aerial view

showing the machine in operation. |

| The operator has light finger-touch controls which

allow for a large degree of control and latitude to perform an

excellent pipe bend.

The machine was assembled by Bigwoods and put into service in

the Birmingham area in about 1982. It originally accommodated

the pipe-bending requirements of Britain’s Trident nuclear

submarine program at Vicker’s U.K. yard.

Sometime in the late 1980s it was moved to the premises of

Mitsui Babcock in Renfrew and used to bend pipes for Babcock

built power stations throughout the world and North Sea oil

installations. |

|

A large pipe leaving the machine with the

operator monitoring the induction heating. |

| Rebirth

In 1998 the Babcock plant closed and was turned into a glass

storage warehouse. The pipe-bending machine was purchased by

Triple DDD Bending of Calgary, Alberta, Canada. It was

decommissioned, disassembled and transported to Canada under the

watchful eye of Project Manager Syd Maskey. The company is

building a new plant to house the Bigwood machine and a draw

bending machine on land at Glenmore Trail and 48th

Street, Calgary. The now outdated induction heating and control

system will be replaced with modern technology and the Bigwood

Induction Bender will be housed in a purpose built 70ft x 200ft

factory at 4715 Glenmore Trail S.E., Calgary, Alberta, where it

will hopefully have a long and useful life. |

|

A final view of the machine in

operation. |

|

I would like to thank Mr. Syd Maskey and Mr. Pat Jordan for

their help in producing this history of an important

Wolverhampton-made product.

|

Return to the

previous page |

|

|