|

New Works at

Wolverhampton

London has now lost practically all the large

engineering works it once had. One by one they

have been transferred to the Midlands, the North

of England, Scotland, and other parts of the

United Kingdom where better facilities for the

metal working industry are to be found. Although

this process of removal has been going on for

years, firms are still taking their departure;

but it seems that the time cannot be far distant

when none but very small works will remain. In

common with many other manufacturing firms,

Chubb and Son's Lock and Safe Company has been

compelled to consider the best means for

providing for a larger output. The company's

present chief works for safe making are in

Camberwell. S.E., but seven years ago as an

experiment, the firm opened a small branch works

alongside its lock works in Wolverhampton, the

object being to test the facilities and the

relative cost of manufacture in London and in

Wolverhampton. In addition to initiating this

practical test, they carefully considered the

relative advantages of ultimately establishing

larger works at other manufacturing centres or

in some country district.

The outcome of all the firm's inquiries and

of the practical experiment with the temporary

overflow works at Wolverhampton is that the

directors came to the conclusion that

Wolverhampton was undoubtedly the most suitable

place for carrying out the firm's manufactures.

They also believed it to be one of the most

convenient places for workmen to obtain

excellent and cheap housing. In consequence the

company has purchased a freehold plot of land,

10 acres in extent, situated on the Wednesfield

Road., just inside the borders of the borough of

Wolverhampton, and within a few minutes of the

goods stations of the London and North Western,

Great Western, and Midland railways. On this

site fine new works have been erected, and they

were formally opened by the Lord Mayor of London

yesterday. Not only are these works close to

many houses and cottages suitable for the

workmen, but within a short distance a large

garden suburb is being planned, and upon this it

will be possible for the men to obtain or lease

modern cottages of an exceptionally good type

and at a reasonable cost.

Before entering upon a description of these

new works a few remarks relating to the history

of the firm may prove of interest. The business

now carried on under the name of Chubb and Son's

Lock and Safe Company was commenced in the year

1818, when Mr. Charles Chubb, aided by his

brother, Mr. .Jeremiah Chubb, invented the Chubb

detector lock. From that date to the present

time, although alterations have been made in the

form and arrangement of the lock, the principles

remain the same, and the firm claims that no key

lock has since been invented which can

successfully compete with it for security.

After the death of Mr. Charles Chubb in 1846,

the business was carried on by his son and

partner, Mr. John Chubb, till the year 1872,

when, upon his death his sons succeeded him as

sole partners until the concern was converted

into a private limited company in the year 1882,

since which time it has been chiefly owned and

entirely managed by members of the family in

conjunction with a board of directors. When the

business was started it was confined to the

making of locks, later on the manufacture of

safes, strong rooms, and safe deposits was taken

up, and at the present time, this latter branch

of the business has grown to very large

dimensions.

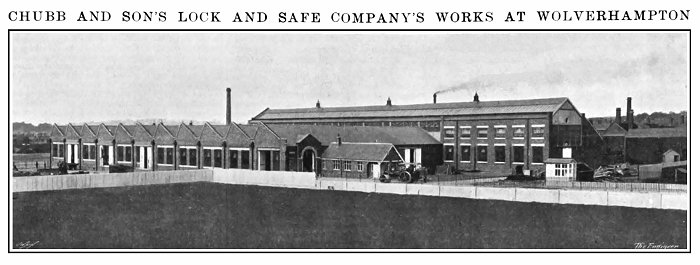

The foundation stone of the

new factory opened last Thursday was laid by Sir

George Hayter Chubb, on the 8th July, 1908. The

works, which are shown here cover an area of

63,500 square feet, and as will be gathered from

the plan, a good portion of this area is set

aside for erecting purposes. The plan, although

not quite correct as regards the arrangement of

some of the machinery, will serve to show the

general layout and the methods the firm has

adopted for turning out its manufactures. The

large erecting shop at the back of the centre

line of machine tools is set aside for the

construction of steel strong rooms, treasuries,

and safe deposits; it is 850 feet long and 40

feet wide, with a height of 38 feet clear of all

girders and roof principals. The height of the

remainder of the factory is from 16 feet to 14

feet at the lowest point. One inaccuracy in the

plan to which attention should be called is that

this large shop just referred to, has been

extended 75 feet to the right of the other part

of the works, as can be seen from the

illustration of the exterior of the works.

Nearly the whole area is undivided by parting

walls, and the general design of the buildings

gives the maximum amount of light, avoiding as

much as possible direct sun rays. Careful

consideration has also been given to the

question of sanitation and ventilation.

The centre part of the

works where the greater number of the machine

tools are situated is where the ordinary office

safes will be constructed. There are twenty five

standard sizes of these safes, and there are

also many intermediate patterns which are fitted

up to meet various requirements. The firm's

object in designing these works has been to

arrange the machines, so that as the work passes

from one tool to another, the material which

entered the door at one end gradually assumes

the form of finished articles and ultimately

leaves at the opposite end of the building,

without during the course of manufacture, having

travelled very far out of a straight line. The

part of the building shown on the lower part of

the plan has been set aside for special safe

work, and it is here where the plan is again a

little incorrect, the final arrangement being to

erect some of the machine tools shown in the

right hand bottom comer of the plan in the

spaces between the second and last row of

benches counting from the left. The benches also

run in the opposite direction to that shown in

the drawing. The group of machine tools marked 5

H.P. will also be erected in the space between

the second and last row of benches. Now, turning

to the centre row of machine tools, which are

already erected, and upon which, as previously

stated, the twenty five standard sizes of office

safes will be manufactured, the first machine

met with on the right is a plate roll by Craig

and Donald, of Johnston.

Two sets of rolls are shown

in the drawing, but up to the present only one

of these has been put down. Here the plates are

first rolled, and they are afterwards passed on

to the blocks where the flattening process is

completed by hammering. These levelling blocks,

only one of which has so far been erected, are

made of armour plate from the original and now

obsolete Dreadnought. The flattening of these

plates is an art to which safemakers attach some

importance and pride.

Having been flattened, the

plates are then passed on to a large edge planer

by J. Buckton and Company of Leeds. The work is

held down on this and other machines

hydraulically, thus saving an enormous amount of

time. Next to this edge planing machine there is

a heavy punching machine by W. Smith and Company

of Glasgow, on which the necessary holes in the

thick plates are punched. Then in the same line

of machine tools we come to a very handy machine

for counter sinking holes, which has been

supplied by John Hetherington and Sons, Limited,

of Manchester. The drill carriage can be run

along in a straight line, and the holes in the

various parts used in the construction of these

safes can consequently be countersunk with great

rapidity.

A point to which attention

should be directed is that a centre punch or a

foot rule are never used in the manufacture of

the company's standard safes. When a man

commences a drilling job, for example, he has

handed out to him from the stores the necessary

jigs and an instruction sheet, and in this way

marking off work is entirely dispensed with. The

last operation performed on the heavy plates, by

means of the machines in the centre of the

building, is that of bending, this being carried

out by means of two hydraulic presses shown at

the left of the row of tools which have just

been considered. The larger of these presses,

which is used for the longitudinal bending, is

by Hugh Smith and Company Limited, of Possil

Park, Glasgow, whilst the smaller is by Hollings

and Guest Limited, of Birmingham. It should be

mentioned that above all these machines, in the

centre of the building, there is a mono-rail,

and in addition, as can be seen from the plan,

there are special roller benches at the sides of

these machines, so that the operation of

conveying heavy plates from one tool to another

and placing the work in position is considerably

simplified, and this, together with the close

proximity of one tool to another, should be the

means of saving much time. The roller benches

are arranged to support the work whilst the

punching or drilling or whatever other operation

is being performed is in progress.

It will be seen from the

plan that the welding department is directly

opposite the line of machines just dealt with,

and that the safes can be lifted by a travelling

crane into this department. The welding at these

new works is to be carried out by the

oxy-acetylene method, an acetylene gas

generator, together with the other necessary

equipment having been supplied by the British

Oxygen Company, of Westminster. The gas

generator is in a well ventilated house

adjoining the main building. The ordinary system

of welding is used at Camberwell, but in this

new factory an endeavour has been made to take

full advantage of everything modem, and the

oxy-acetylene system has consequently been

adopted, and it is possible, we understand, that

this process will ultimately be employed for

cutting.

When the welding process

has been completed the next operation consists

of grinding off the rough parts so as to give

the safes a perfectly smooth surface. This

operation, as will be gathered from the plan, is

performed in the apartment next to that in which

the welding process is carried out. Here a

special grinding machine has been erected, with

which all the rough parts set up in welding are

removed. This grinding machine has been

constructed by John Holroyd and Company, of

Milnrow, near Rochdale. It consists of a long

vertical column and an overhanging arm similar

to that of a radial drilling machine. This arm

carries a revolving emery wheel mounted at an

angle, by means of which the rough places on the

safes are removed. The arm carrying the emery

wheel can be raised or lowered over a wide range

in order that work of various dimensions may be

dealt with. The machine is driven by means of a

vertical motor fixed at the top. The proofing

chamber in which the proofing material is

inserted between the inner and outer cases

adjoins the grinding department. From the

proofing shop the safes pass into the paint shop

and the drying room, and finally into the stores

or packing department, depending upon whether

they are to be dispatched or kept in stock.

There is, of course, a

considerable amount of comparatively light work

in connection with the fittings and lining of

these safes, and for punching, drilling, and

cutting the lighter parts there is a number of

smaller machines at the side of the line of

heavy tools previously referred to and shown on

the plan. There are small drilling machines, a

punching machine by Bliss and Company, shears, a

circular saw, and a fine radial drilling

machine, the arm of which revolves on ball

bearings. This latter tool has been supplied by

W. Asquith, Limited, of Halifax. It should be

mentioned that nearly all those machines shown

on the centre of the plan are at present

erected, whilst some of those shown at the top

and bottom of the plan will be put up later. The

smiths' shop was also in a rather unfinished

condition when we visited these works a few days

ago. Ultimately it will contain five hearths,

which are all being put in by James Keith and

Blackman and Company Limited, who are also

supplying the blower.

We may remark here that an

entirely new departure in the construction of

safes is being undertaken which embodies all the

best known principles, such as heavy 12 bend

bodies with welded corners, asbestos inner

doors, and inner and outer doors of new design

built on the external lock case principle.

A vertical boiler has been erected in the

smiths' shop for supplying steam for heating the

drying room. The hydraulic pumps and accumulator

are also erected in this shop. The pumps have

been supplied by Hugh Smith and Company of

Glasgow. There is also an electro pneumatic

hammer by B. and S. Massey, of Manchester. It is

in this shop that the hardening is to be carried

out. A double furnace for hardening two large

plates at once for strong- rooms will be

provided, and electric instruments for measuring

the temperature so as to ensure the plates are

not being overheated. The plates are heated to a

cherry red and then plunged into a tank of water

through which a continuous supply of cold water

flows. Although it may appear from the

illustration showing the exterior of the works

that a power plant has been put down for driving

the machinery owing to the presence of the tall

shaft in the background, this is nevertheless

not the case, the shaft in question belonging to

the works of J. Evans and Son, which are in

close proximity.

The whole of the machinery

in Chubb's new works is driven by three phase

induction motors, all of which are of the

squirrel cage type. Three phase current is taken

from the Corporation mains at a pressure of

5,000 volts. It is transformed down to 400

volts, and the current at this pressure is

supplied to thirty motors of various sizes

ranging from 2½ to 20 horsepower. Naturally,

each large machine has its own motor, whilst the

smaller tools derive their power from shafting,

one motor thus supplying power to a number of

the smaller tools. The whole of the motors have

been supplied and erected by the British

Westinghouse Company, of Trafford Park,

Manchester. They are all of the open type, and

many are mounted direct on the machines which

they drive, the power being transmitted direct

without the use of chains or belts. Many of the

starting switches are mounted on the walls, and

in the case of the large motors the starting

current is limited by means of the star to mesh

connection. In the case of the small motors,

however, simple resistances are used for

starting. The type of switchgear used is simple

and strong, and admirably adapted for workshop

use. In many instances ammeters are fixed to the

starting switch, and enable the operator to see

how much current the motor is taking, and so to

judge when the change from the star to mesh

connection should be made. The wiring is also

admirably suitable for workshop use, armoured

cables being employed. Usually, where electric

power is available, workshops are lighted by

means of arc lamps, but in this instance Osram

lamps have taken their place. Lamps of 100

candle power are used, and are suspended by

flexible wires in the usual manner. Additional

lamps, we understand, are to be provided on

those machines where a good local light is

needed. The periodicity at Wolverhampton is 50.

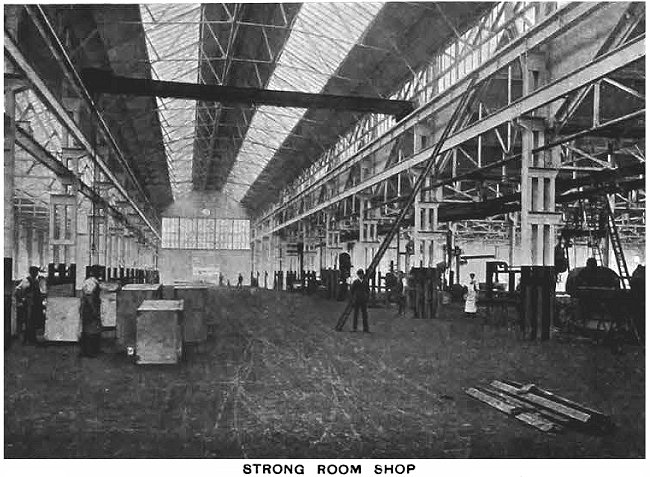

For lifting the plates in

the large shop where the strong rooms are to be

manufactured, a travelling magnetic crane is to

be erected. Alternating current for a magnetic

crane is, of course, quite unsuitable, and to

overcome this difficulty a continuous current

dynamo is to be driven from the shafting. This

will charge a storage battery so that continuous

current for use on the crane will always be

available.

A small block of temporary

offices has been provided, adjoining the main

factory, and a foreman's cottage is in course of

construction. The protecting fences and walls

enclose an area of about 20,300 square yards.

The approach from the Wednesfield Road is by a

wide private cart road. A large piece of land is

retained at the back of the factory for future

extensions, to which additional access has been

provided from the Woden Road. In the meantime it

has been placed at the disposal of workmen and

others for sports. A bowling green has also been

laid down.

The whole of the factory

buildings have been designed on lines carefully

thought out by the present directors and

successfully carried out by their architect, Mr.

G. Gordon Stranham, of Bush Lane, Cannon Street,

London, E.C. Mr. C. H. M. Mileham, of Lincoln's

Inn Fields, has acted with him as consulting

architect, and Mr. F. T. Beck, of Wolverhampton,

as local superintending architect. Mr. F.

Simpson was the general clerk of the works. The

contract for the buildings was placed in the

hands of Henry Lovatt, Limited, of

Wolverhampton. The steel construction is by

Drew, Bear, Perks and Company, of London. The

consulting electrical engineers were the British

Engine, Boiler and Electrical Insurance Company,

Limited, of Manchester. |