|

Tack Manufacturing: The Later Years

The manufacturing process had now been

perfected and no further changes to the

machines were necessary. A girl could now feed 15

machines and a fitter could look after 15 machines. After

bluing, the tacks were put into pans and transported up an

elevator to the floor above, where they went around a gravity

fed roller conveyor to cool. After cooling they were weighed and

put into the appropriate packaging as requested by the

customer. The company’s brands were “Lion Brand” and “Bugle

Brand”.

|

|

The tacks were noted for their quality, clean finish and sharp

points. Tacks were also available in a zinc-plated finish or

made from copper or aluminium, for use in boats and roofing.

Most of the tacks were exported to many countries including:

America, Hong Kong, Malaysia, Germany, Switzerland, West Indies,

Panama and Malta. Requirements varied from country to country.

Some wanted lighter tacks or smaller heads and these differences

had to be catered for. |

| In the 1970s the Crown Nail Company broke into

the American Market and between 10 to 15 tons of tacks at a time

were sent to one customer alone. At this time the Chinese tack

manufacturers started supplying cheap tacks to North America and

the Americans started buying them in preference to the more

expensive British variety. This was a blow to the Crown Nail

Company and as a result the factory went on short time for a

while. About 18 months later the Americans once again started

buying the superior Wolverhampton product in preference to the

cheap Chinese tacks, because of a large number of complaints

from customers. One of the Crown Nail Company’s last production

runs was for an American customer. It was for 13 tons of special

stake tacks with a dimple in the head, and tip nails to hold

steel shoes on foundry boots. |

| In later years it became difficult to attract

young people into the industry, which was perceived as being

dirty, with a lot of heavy manual labour. In the mid 1980s there

was a price war. |

|

|

The company’s main competitor drastically

reduced the price of its tacks and everyone else followed. A

little while later production ceased at the competitor’s works.

The Crown Nail Company’s efficient production techniques had

paid off yet again.

The tacks were produced in a size range of

6mm to 32mm and were packed in 500gm, 2.5kilo and 10kilo boxes.

Most tacks are now sold in bubble packs and small cartons in

D.I.Y. stores. In later years about 99 per cent of the Crown

Nail Company’s tacks ended up this way. This resulted in a three

fold increase in the price of the tacks after they were sold to

the distributor who could purchase them in bulk 25 kilo and 10

kilo cartons.

|

|

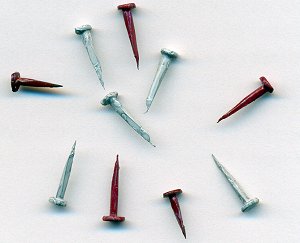

Gimp Pins.

|

One of the Crown Nail Company’s products was gimp pins,

which are used by upholsters. They have a thin head and are

coloured to match the furniture. The colouring is done by

placing 25 kilos of the tacks in a rotating barrel with internal

metal vanes. Paint is poured in and the tacks are coloured. It

is essential that the paint is lead-free, because many

upholsterers put the tacks in their mouths and so cellulose

paint is used. Gimp pins are rapidly disappearing because of the

introduction of staple guns and today they are only used on

hand-made furniture. A similar tack was also produced for

shoemakers. |

| Next door to the works, in

the front room of one of the old houses was Crown Stores. The

shop was owned by one of the company's employees and run by his

wife. They sold sandwiches, bread, sweets, cigarettes and

tobacco.

Photograph courtesy of Mary Ashleigh. |

|

|