|

The Wolverhampton Die Casting

Company Limited was formed in 1919 at a small factory in Great Hampton Street. The

company rapidly leapt to the forefront of the industry

to become the largest pressure die casting organisation

in Europe. By the 1950s over one hundred and fifty

million zinc and aluminium alloy pressure die castings

were produced each year, for over 700 customers in 30

different industries. Castings were produced to very

fine limits to eliminate practically all machining. |

|

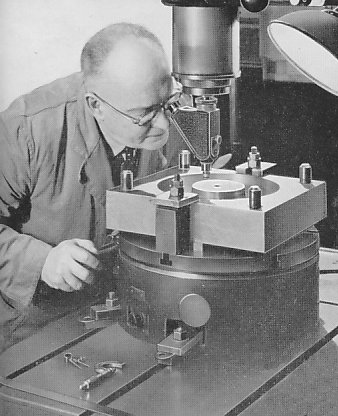

A diesinker at work.

The dies were constructed from

solid forged blanks of special die steel, and in much of

the work, particularly in the case of a delicate and

detailed job, the skill of the hands of the diesinker

cannot be over-estimated.

In many cases even the most

modern machinery cannot perform the intricacies

required. |

|

In February 1934 the company

acquired part of the A.J.S. site at Graiseley Hill, on

which to build a new factory, in order to expand

production.

Success continued, and further

expansion followed. The ‘Hollies Works’ was built on the

other side of Graiseley Hill, and a factory was acquired

at Ludlow. The total factory floor space now amounted to

nearly 400,000 square feet.

In 1950 an affiliation began with

the Precision Castings Co. Inc. of Fayetteville, New

York, the largest pressure die casting organisation in

the United States, which operated from nine separate

factories.

The association between the two

companies enabled them to keep up-to-date with the

latest technical advances in each country. |

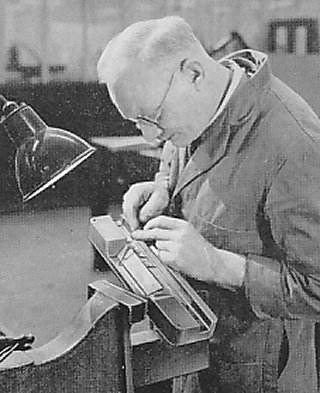

Another view of a diesinker at

work. |

|

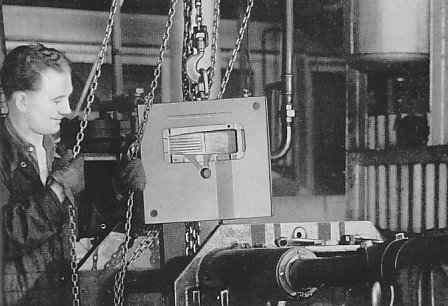

At work on one of the

specially designed automatic casting machines in the

foundry. |

|

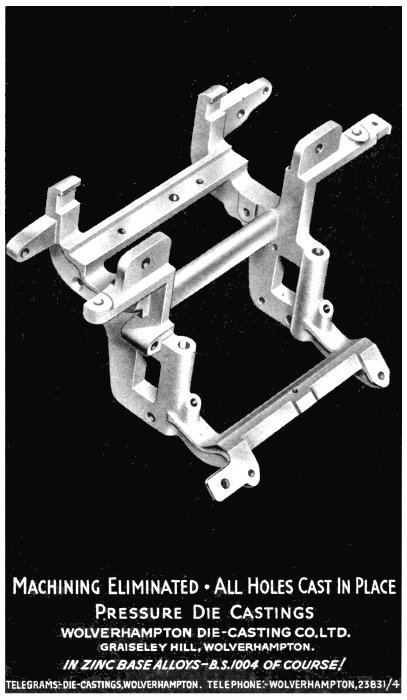

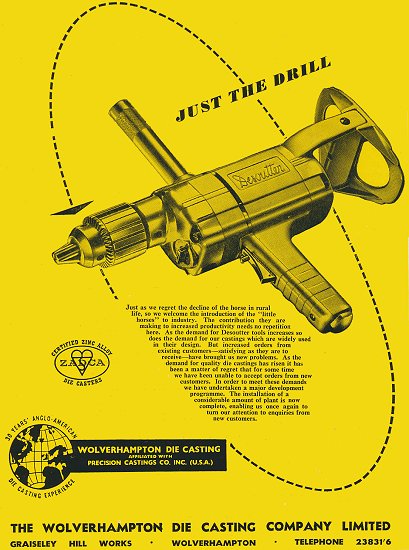

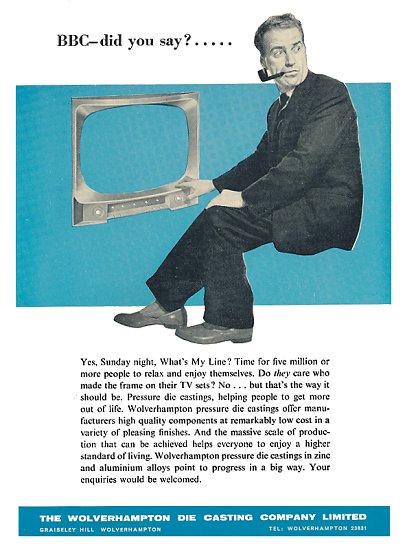

An advert from 1948. |

|

|

|

|

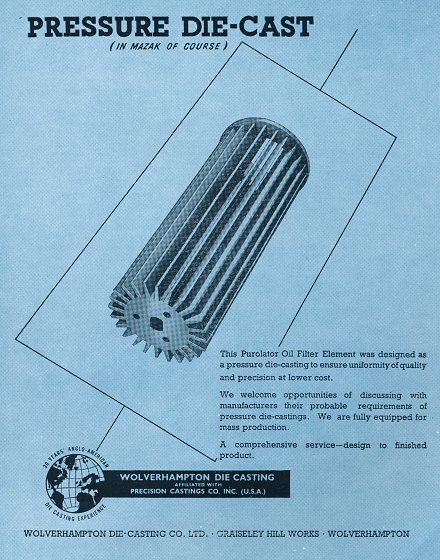

An

advert from 1949. |

|

An advert from 1953. |

|

|

In the mid 1960s the company joined

forces with British Pressure Diecasting Limited of New

Barnet, which had two factories, one at New Barnet and

another at West Chirton.

The Wolverhampton company employed

over 2,300 people, 60 percent of whom were men, and 40

percent women.

It was clearly a good place to

work, with a family atmosphere. It was not uncommon for

several generations of a family to be employed there,

and a considerable number of the employees were related.

Many of the draughtsmen in the

drawing office where exceptionally well qualified, and

experienced, and carried out design work on customers'

components before the dies were made. |

An advert from 1956 |

|

An advert from 1958.

|

In the laboratory, the

specifications of the zinc alloy and the various

aluminium alloys cast in the foundry were regularly

checked, to ensure that the high standards of purity

necessary for the production of castings, were

maintained.

Routine checks of the alloys, and

visual and photographic X-ray examinations of castings,

were regularly carried out.

Routine checks were also made in

the foundries on the quality of the surface finish, so

that a high standard was always maintained.

Inspection of castings was carried

out at various stages in the production sequence, and

more than 120 people were provided with special tooling

for this work.

By the mid 1950s the foundries

covered around 95,000 square feet, had 800 staff, and

produced approximately 3 million castings each week.

There was a separate polishing and

plating department where castings could be plated in

copper, nickel, chromium, gold, or silver. |

|

In order to ensure a supply of

well-trained people, an apprenticeship scheme was

developed in conjunction with Wolverhampton Technical

College.

Young men were instructed in

casting, plant maintenance, machine shop work, plating,

polishing, electrical engineering, metallurgy and die

designing.

Special technical courses were

offered to the apprentices who showed the necessary

ability and initiative, and these often led to

appointments in key positions, both in technical and

administrative fields.

The Welfare facilities for

employees included both indoor and outdoor sports, and

social activities. The sports and social club was

extremely popular.

A contributory pension scheme was

in operation, and employees automatically became members

of a non-contributory pension scheme after ten years

with the company. |

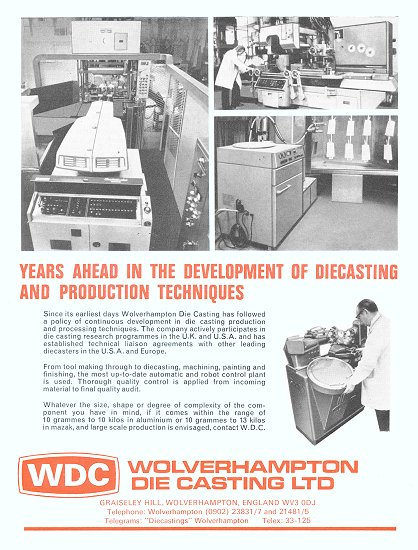

An advert from 1965. |

|

An advert from 1954. |

Advertising for apprentices in 1967.

|

An advert from 1974.

|

In 1977 the business was acquired

by Worcestershire based Mitchell Somers.

Things started to go wrong in the

recession in the late 1970s when orders declined. The

company began to make a loss, and was sold to Cookson in

1985.

The business became Metal Castings

Limited, but sadly closed on the 16th December, 2004.

All traces of the Graiseley Hill

factory have now disappeared, the site will soon become

a shopping centre. |

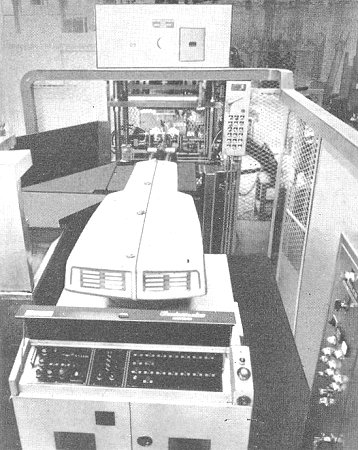

| An example of the up-to-date

machinery that was used on the site. Industrial robots

were very new at the time. |

|

|

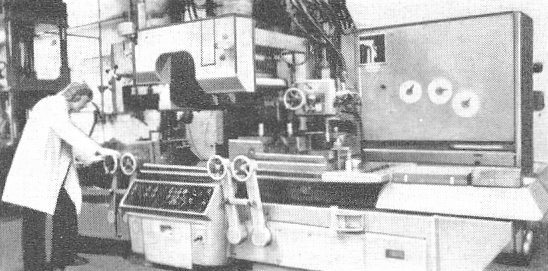

Another example of the modern

manufacturing facilities at Graiseley Hill, and the

investment that was put into the factory. |

|

Return to

the

engineering hall |

|