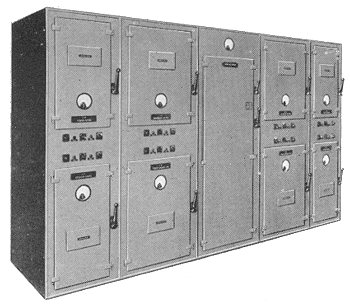

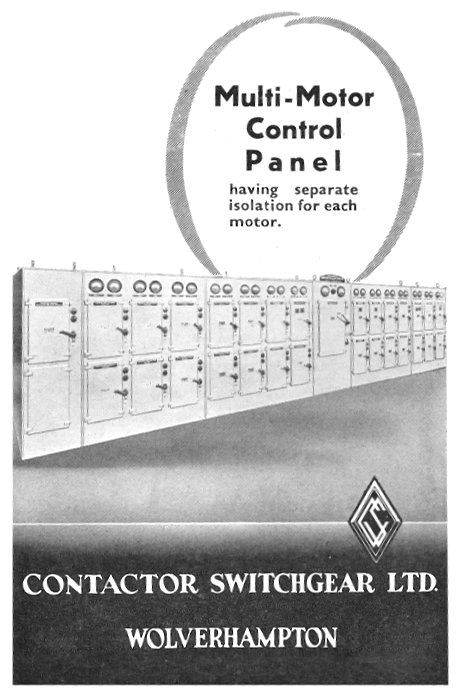

A power station boiler auxiliary motor

control board with individual isolation for each panel. |

The company was founded by Harry Rayner and Jeanne

Liwski in October 1936. They obtained a licence which allowed

them to manufacture switchgear that was designed by La

Telemecanique Electrique, a French company. Harry and Jeanne

obtained premises in Moorfield Road and started with just 6

staff.

The high quality switchgear sold well and the company soon opened a new machine shop. The Moorfield

Road works had a number of departments including the Test Dept.,

Sub-Assembly Dept., Sheet Steel Dept., Development Dept.,

Inspection Dept., Stores and the Company Office. |

| The switchgear was built to a high standard and

the workforce was proud of the company's products, which

included contactors and automatic electric control gear up to

1,000H.P. This was used to control such things as A.C. motors up

to 5,000 volts, electric furnaces, machine tools and rolling

mills. The number of employees grew rapidly and by 1957 had

reached 600. Many people enjoyed working in the happy family

atmosphere so much that they stayed there for the rest of their

working life. |

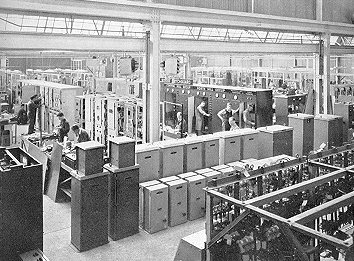

The Main Assembly Bay where control boards

and starting panels are being assembled. |

| Sales were good and in order to increase

production more space was required, so in 1959 the company

decided to build a new factory at Leominster in Herefordshire.

Some departments moved to the new works and others such as the

Test Department stayed in Wolverhampton. By this time there was

a large spares market for the company's products, both for

repairs and modifications to existing installations.

In the late 1960s the company produced the Tactorstat logic

controlled, electronic, automatic control gear. This was

extremely reliable, had a long life and operated at high speeds,

because it had no moving parts due to its solid state design.

The system could also operate in locations where the equipment

would be subjected to atmospheric pollution or dust.

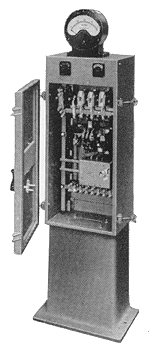

The photograph shows a standard 'direct

on' contactor for use in A.C. motor starters. |

|

|

The company's other control gear could operate up

to 6,600 volts A.C. and 650 volts D.C. It was used in iron and

steel works, power stations, rolling mills, mechanised

foundries, sewage works, chemical plants, gas works and cement

works.

In 1969 Contactor Switchgear was taken over by M.T.E. and

the company stopped making its own parts. M.T.E. parts were used

instead. The Leominster factory was closed and 120 people made

redundant. By this time Harry Rayner had died and Jeanne Liwski

was nearing retirement.

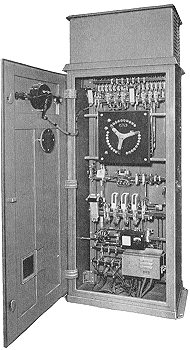

The photograph shows the control panel

at Goldthorn Hill Repumping Station that was built by Contactor

Switchgear. |

|

An advert from 1948. |

|

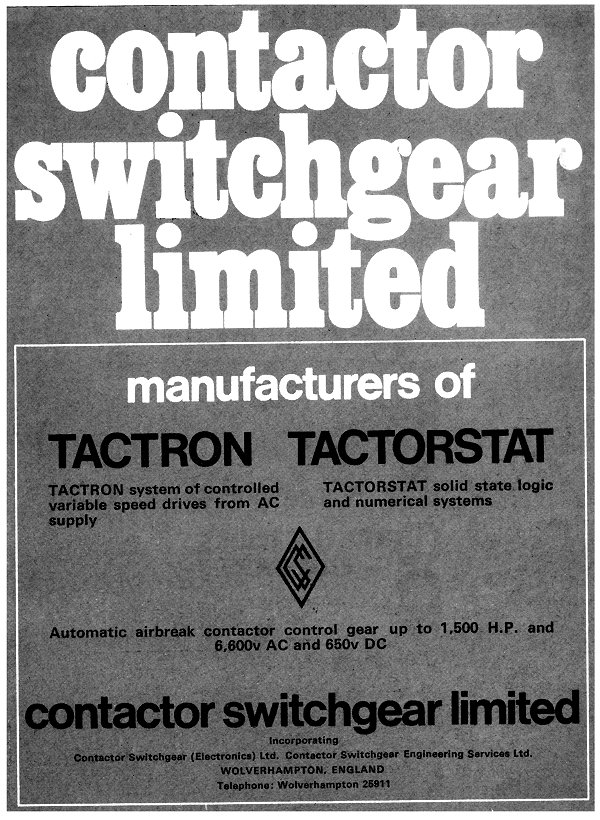

An advert from 1970. |

|

Sales started to fall and in 1974 M.T.E. was taken

over by R.H.P. who made ball bearings. R.H.P. planned to close

the Wolverhampton factory and sell the buildings. Luckily one of

Contactor Switchgear's old customers, Lawrence Scott and

Electromotors stepped in and purchased the company, which saved

the day.

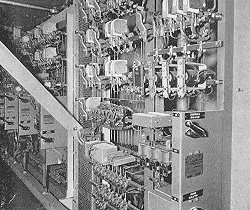

The photograph shows part of the

control panels which were built by Contactor Switchgear for use

with a high production grabbing crane at Stewart and Lloyds in

Bilston. |

| In 1980 Lawrence Scott and Electromotors became

part of Mining Supplies, who already had a switchgear division.

There were further redundancies and by 1984 the workforce had

fallen to 120. Sales fell and in October 1985 the company

started a three day working week. This continued until the

following February when sales started to pick-up again. |

Part of the works at the end of Moorfield

Road. On the right is part of Turners factory.

Courtesy of Jim Boulton. |

The end came in July 1986 when Mining Supplies was taken over and it

was announced that Contactor Switchgear would close, on October 31st. It

was a sad end to a company that produced such high quality products.

|

|

|

Return to the list of

manufacturers |

|