Ever Ready Radios

The Early Years and Lissen

Britain was slow to electrify and many of the

rural areas remained without electricity for a long time. Due to this

there was a large battery market and for many years large numbers of

radio batteries were sold. In 1934 the sales of high tension radio

batteries exceeded 15 million. The Ever Ready Company (Great Britain)

Limited was the market leader and was part of an international group

that originated in America at the turn of the century. It was

incorporated in Canada in 1932 and the British company held quite a

number of the shares.

|

|

|

The History of Radio |

|

In 1928 Ever Ready purchased Lissen Limited from

its owner and Managing Director, T. N. Cole, for over 1 million

pounds. Thomas Noah Cole was born in 1891 at Llanllwni, near

Lampeter and brought up in Cardiff. He was interested in

football and a keen supporter of the Cardiff team. His father

was a marine engineer and Thomas's first job was selling bananas

from a hand cart.

In the early 1920's there was a lot of

interest in radio and he realised that there would soon be a

large market for radio components. With this in mind he moved to

London and set up the Lissen Company.

In 1923 he formed Lissen

Limited, with works at Shepherd's Bush, to sell a large range of

components, most of which were made at the factory. Thomas's

wife Rebecca was the main shareholder and the company was very

successful, employing around 3,000 people by the mid 1920's. |

|

The company had three factories, one produced batteries and the other two

produced components. The company sold everything that was required to build a

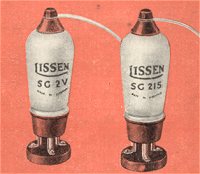

radio. There were Lissen valves, resistors, capacitors, coils, transformers,

loudspeakers and cabinets.

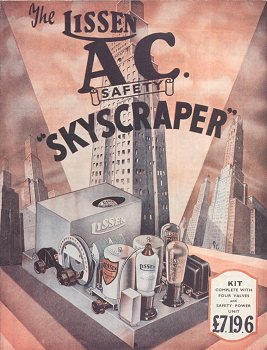

Lissen also produced a range of complete radio kits

under the name of Skyscraper, and published plans which encouraged builders to

solely use Lissen components, suggesting that to do so would produce a receiver

of superior quality. Ever Ready continued producing Lissen components and radios

until the beginning of the second world war, after which the Lissen name ceased

to be used. |

The Lissen Skyscraper 4. |

|

|

|

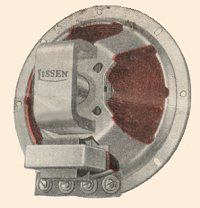

A Lissen moving coil

loudspeaker from the early 1930's. |

|

The circuit diagram of the Lissen

Skyscraper 4.

|

When Ever Ready purchased the company, part of the

deal was that Thomas Cole would remain as Managing Director, but

for 10 years he would not get involved in any business venture

that would be in direct competition with Lissen Limited.

Eventually he would come to regret not being his own master, and

in 1934 purchased the ailing Burndept radio company and founded

a new battery company called Vidor. |

Vidor was named after the initials of Thomas's two daughters, Valerie and

Denise, and his Wife Rebecca. As a concession to Ever Ready and his agreement

with the company, he did not run Burndept and Vidor himself, but employed Mr.

R.P. Richardson as Managing Director. In 1935 Thomas brought an action appealing

against the agreement and engaged Sir Stafford Cripps, and two other eminent

lawyers. On the eve of the action, an out of court settlement was made and from

that time on, relations between Ever Ready and Vidor were strained. This wasn't

helped by the fact that Vidor batteries were popular with radio dealers, because

the company offered a 25 percent discount and the batteries sold at a very

competitive price.

The Move to Wolverhampton

|

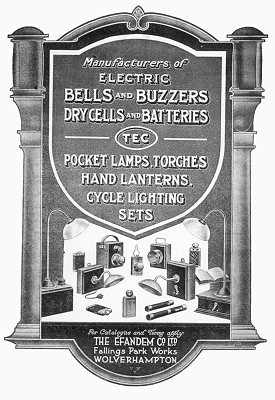

An Efandem Co. Ltd. advert from 1920. |

In 1911 the Efandem Company Limited moved from Birmingham

to new premises at Park Lane. The strange name Efandem (F & M )

came from the initials of the two directors.

The company produced a wide

range of electrical goods including batteries, torches, hand lanterns,

searchlights, sirens, car and bicycle lighting sets, hand lamps, torch

cases, bells, buzzers, and friction clutches for machinery. |

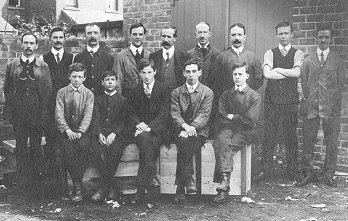

| A photograph of the Efandem staff in

1913. |

|

|

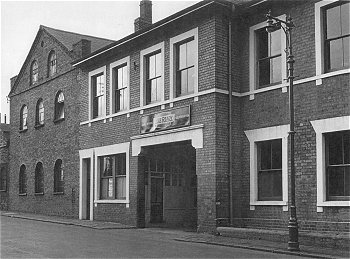

The front of the Ever Ready factory in Park

Lane, in 2001. Most of the building has since been demolished. |

| During the first world war production was concentrated on

the war effort and the items produced included torches, torch batteries,

searchlights and sirens. After the war the company was in a poor

financial state and the Managing Director was convicted for embezzling

several thousand pounds.

As luck would have it, Ever Ready was

interested in the factory and purchased the company in the mid 1920s. The works went on to employ nearly 3,000 people and produced large

numbers of dry batteries and radio receivers. |

|

Ever Ready's Canal Works in Lower Walsall Street.

photo courtesy of Trevor Ridgeway. |

A few years later, motorcycle and vehicle manufacturer,

A.J.S., went into liquidation and the company's Lower Walsall Street

Works were put onto the market.

The works were sold to Ever Ready on

25th January 1932, for £12,750, and went on to become an important

centre for the manufacture of torches. The works became known as Canal

Works. |

The Radio Era

Ever Ready's commercial policy was to encourage the use and production of

battery powered equipment, and with this in mind the company entered the radio

manufacturing business. The first two Ever Ready receivers appeared at the

beginning of 1935 and strangely one of them was mains powered. Initially Ever

Ready collaborated with Pye and Mr. Charles Orr Stanley who owned Pye, was

invited onto Ever Ready's Board as a non-executive director. The chassis and

cabinets were made by Pye and put-together at Ever Ready's Finsbury Park

factory, which was supervised by Pye management. The collaboration only lasted

for a few years. Just before the war Charles Stanley fell out with Magnus

Goodfellow, who was Ever Ready's Chairman, and the venture came to an end.

|

|

|

|

The Sky Baronet valve portable. |

The Lissen factory at Islington was still in production and at the beginning

of the second world war it obtained a ministry contract to assemble and repair

"Comfort Sets" for the armed forces. All went well until 1941, when the factory

was destroyed in an air raid. The company was tied to the ministry contract and

so it was essential to quickly find new premises, and continue production.

Initially manufacturing began again at Amersham, Buckinghamshire, but the

buildings were too small and unsuitable for this kind of use. Space was found at

Canal Works and in 1942 Ever Ready began to build radios in Wolverhampton. More

space was still required and so the radio department soon made its final move to

Block 'A' of the Park Lane works.

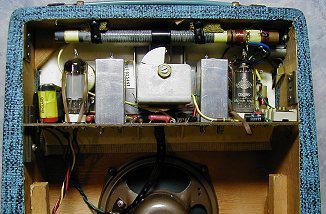

| Although the radio department was situated in a part of

the battery works, it operated as a separate unit and reported directly

to the company's Board of Directors. After the war, the department began

to produce radios for the civilian market, and all future Ever Ready

radios were designed and built here, except for the Type 'B' of 1947,

which was built by Plessey.

The first receiver to be produced after the

war was the Model 'A', which was a development of the wartime "Comfort

Set". It was a heavy 4 valve superhet in a wooden case with a crackle

paint finish. The controls and carrying handle were on the top, and it

was powered by a B103 battery. |

The Sky Captain. |

The next model produced here was the Model 'C', which was still as heavy as

the Model 'A', but had a more elegant appearance. One notable early receiver was

the 'J' Type or "Saucepan Special" which was launched in September 1949.

Laurence Orchard was one of the company's senior executives. In 1948 he was on a

visit to Ever Ready's South African subsidiary, BEREC ( the British Ever Ready

Export Company).

|

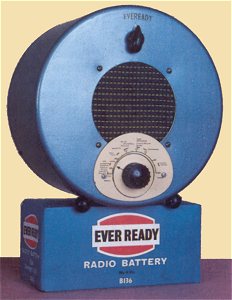

The Saucepan Special. |

While there he was approached by the man in charge of

broadcasting in Nyasaland and Rhodesia. He wondered if Ever Ready could

produce a tropicalised dry-battery radio that could sell for £5, as this

was all that many members of the rural community could afford. The

company rose to the challenge and developed a small 4 valve shortwave

receiver that was powered by a B136 battery.

One problem was to find a

cheap housing for the receiver. This was cleverly solved by using a

blue-sprayed metal case that was made by the British Aluminium saucepan

factory. It was basically a 10inch saucepan with the handle removed and

a hole punched in the bottom for the loudspeaker. The radio sat on the

B136 battery, which was too big to fit inside. The radio was sold in

many parts of the world, including Malasia, and almost a quarter of a

million were produced. |

The circuit diagram of the Berec 'Ballerina'.

The circuit diagram of the type 'N' from 1951.

The 'J' Type was followed by the 'K' Type and then the 'N' Type, after which

the company began to use the word 'Sky' in most of the names of new receivers.

This came from the old Lissen days when Lissen produced its successful range of

Skyscraper receivers. In 1957 the company produced the Sky Leader, which

was Ever Ready's first transistorised receiver. The company's last valve

receiver was the Sky Captain of 1961. The radios were very successful and

production peaked at about 5,000 receivers per week. The factory produced over 1

million radios.

|

|

|

Early Receivers

Produced in London |

| Model |

Year |

Valves |

| 5007 |

1935 |

K80A, K50M, K23B, K77A |

| 5008 |

1935 |

TP2620, VP1321, PENDD4020 |

| 5012, 5024, 6012 |

1936 |

K50M, K30D, K70B |

| 5016 |

1936 |

A50P, A50B, A70D, A11D |

| 5027 |

1937 |

A50P, A30D, A70D, A11B |

| 5028, 8122 |

1937 |

K50M, K30D, K70B |

| 5029, 5040 |

1937 |

A36B, A50P, A23A, A70D,

A11D |

| 5032 |

1937 |

K80B, K50N, K23B, K70B |

| 5038 |

1937 |

A80A, A50P, A27D, A11D |

| 5010 |

1938 |

K50M, K30K, K30K, K70D |

| 5010, 5118 |

1938 |

K80B, K50N, K23B, K70B |

| 5041 |

1938 |

K50N, K30K, K30K, K70B |

| 5103, 5117 |

1938 |

A36B, A50P, A23A, A70D,

A11D |

| 5203 |

1939 |

ECH3, EF9, EBC3, EL3, AZ1 |

| 5214, 5215, 5216, 5217, 5218, 5219, 5318 |

1939 |

DK1, DF1, DAC1, DL2 |

| |

|

Valve Receivers

Produced at Wolverhampton |

| Model |

Year |

Valves |

| Model 'A' |

1945 |

DK32, DF33, DAC32, DL35 |

| Model 'C' |

|

DK32, DF33, DAC32, DL35 |

| Model 'H' |

|

|

Model 'J' - "Saucepan

Special" |

1949 |

|

| Model 'K' |

|

DK91, DF91, DAF91, DL92 |

| Model 'N' |

|

DK91, DF91, DAF91, DL92 |

| Sky Queen T K |

|

DK91, DF91, DAF91, DL92 |

| Sky Queen |

1953 |

DK96, DF96, DAF96, DL96 |

| Sky Prince |

1954 |

DK96, DF96, DAF96, DL96 |

| Briefcase N3 |

1955 |

DK96, DF96, DAF96, DL96 |

| Sky Monarch |

1955 |

DK96, DF96, DAF96(2),

DL96(2), DM70 |

| Sky Monarch (AM / FM) |

1955 |

DF97, DK96, DF96(3),

DAF96(2), DL96, DM70 |

| Sky Monarch (AM / FM) |

1956 |

DF97, DF96(4), DAF96(2),

DL96(2), DM70 |

| Sky Baby |

1956 |

DK96, DF96, DAF96, DL96 |

| Sky King |

1956 |

DK96, DF96, DAF96, DL96 |

| Sky Princess |

1956 |

DK96, DF96, DAF96, DL96 |

| Sky Lord |

1957 |

DK96, DF95, DAF96, DL96 |

| Sky Casket |

1958 |

DK96, DF96, DAF96, DL96 |

| Sky Emperor |

1958 |

DF97(4), DK92, DAF96,

DL96(2), DM70 |

| Sky Queen 2 |

1959 |

DK96, DF96, DAF96, DL96 |

| Sky Baronet /Countess |

1959 |

DK96, DF96, DAF96, DL96 |

| Skyscraper L26 |

|

DK92, DF96(2), DAF91, DL94 |

| Sky Captain |

1961 |

DK96, DF96, DAF96, DL96 |

| |

|

Transistor Radios |

| Model |

Year |

Transistors |

| Sky Leader |

1957 |

OC44, OC45(2), OC78(3) |

| Sky Leader |

1957 |

OC44, OC45(2), OC71,

OC72(2) |

| Sky Personal |

1959 |

XA102, XA101(2), XB113,

XC121(2) |

| Sky Personal |

1959 |

XA102, XA101(2), OC71,

OC72(2) |

| Sky Baron |

1960 |

XA102, XA101(2), XB113,

XC131(2) |

| Car Portable |

1960 |

OC44, OC45(2), OC82(3) |

| Sky Lark |

1963 |

OC44, OC45(2), OC81D,

OC81(2) |

| Sky Master |

1963 |

AF117(3), OC81D, OC81(2) |

| Sky Tourer |

1964 |

|

| De-Luxe Receiver |

|

|

| |

|

Some of the Berec

Receivers |

|

Berec Ballerina |

| Berec Brigand |

|

|

| Berec Commander |

|

|

| Berec Demon |

|

|

| |

|

|

|

The Radio Department

Everyone in the department worked closely with other members of the team and

helped to maintain the quality of the products. A family-business atmosphere

prevailed and everyone enjoyed their time at Ever Ready.

The management team was as follows:

| Freddy Hillman |

Factory Manager |

| Tom Harrison |

Production Manager |

| George Webster |

Chief Inspector |

| Roland Williams |

Quality Control and Test |

| Bob Lampitt |

Chief Engineer |

| Tom Poulton |

Assistant Factory Manager |

| New products were designed by Bob Lampitt and his team of

engineers and designers. Prototype receivers were subjected to a

critical analysis to determine the best method of assembly. Tom Harrison

(Harry), and Roland Williams and his team, decided what sections were to

be made as sub-assemblies, and what metal pressings were required.

They

also decided on the coils and transformers that would be produced in the

coil winding section, tag boards, battery and loudspeaker leads, silk

screening artwork, for printed items, case covering, and a thousand and

one other things. |

The Sky Master. |

A pre-production batch of six or more receivers were assembled by a select

group, who in co-operation with the drawing office and laboratory, carried the

new model into production. These receivers were used to prove the design,

establish quality standards, test procedures, and timings to determine the "rate

for the job". Once finalised, the assembly of large quantities followed, along

with test, packing and despatch.

|

The end of a day's work.

photo courtesy of Trevor Ridgeway. |

The Ever Ready Van Sales force distributed many of the

finished products to radio shops, outlets selling batteries, general

stores and cycle shops.

Large quantities of receivers were distributed

by BEREC and others were sold to mail order companies and Wireless for

the Blind. |

By 1968 it was all over. Ever Ready decided to close the radio department and

concentrate solely on battery manufacture at Park Lane. Just before closure the

team designed and produced a prototype portable television receiver that ran on

dry batteries. It used electrostatic deflection to reduce power consumption and

was far ahead of its time.

Battery production continued at Park Lane until the spring of 1980, when the

works finally closed. Demand for the company's products had slowly been falling

and the works were no longer profitable.

I would like to thank Trevor Ridgeway and his wife, for all of their help in

producing this section.

|

|

|

Return to the List

of Manufacturers |

|