|

100 Years of

Boiler Making |

|

|

What follows is taken from a booklet produced by John

Thompson Limited, as a memento of the visit to the

factory, made by the Institution of Mechanical Engineers

on the 29th June, 1927. It provides us with a detailed

and accurate description of the company at the time,

with many illustrations.

John Thompson Limited, Wolverhampton

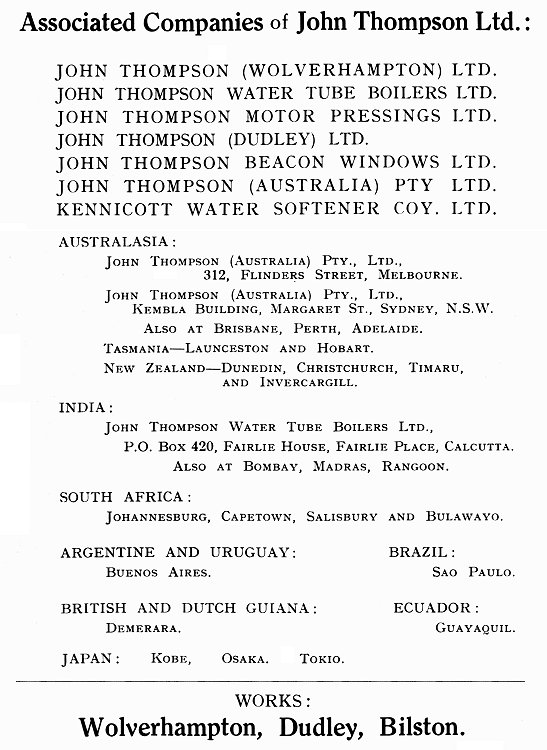

This is a combination of six

companies, all under private ownership, divided so as to

put each branch on its own footing (and to enable

members of the staff in the various sections to be

elected to the different Boards). All of them carry the

name of John Thompson and include:

The Water Tube Boiler Company,

Wolverhampton

The Motor Pressings Company, Wolverhampton

The Boiler & Engineering Company,

Wolverhampton

The Kennicott Softener Company,

Wolverhampton

Beacon Windows Limited, Wolverhampton

The John Thompson Structural Engineering

Company, Dudley |

The Firm of John Thompson was

founded 100 years ago by the grandfather of the present

governing directors, and has made great progress since

1887, and particularly since 1900; it has an unbroken

successful record, and no outside money has ever been

applied for, either public or private.

The productions cover those named

under the different headings above mentioned, and today,

the staff and workpeople number 2,000, and the works and

land total some 35 acres.

|

|

Founders of the firm. |

|

The directorate of John

Thompson Limited, companies. |

|

The main offices. |

|

Lancashire Boilers - the

firm were pioneers in the production of Lancashire and

other boilers in the fewest number of plates and joints,

and for the manipulation of this larger material, a

special plant was installed. They have also been

pioneers in two very important improvements: dished

ends, that eliminates the necessity for any internal

stays or gussets, with which is combined either a

corrugated flue throughout, or a corrugated section,

which secures at one and the same time greater strength,

elasticity, and heating surface. The dished ends are

forged in heavy hydraulic presses, and the corrugated

sections are heated by water gas and welded by hydraulic

roller machines (no hammering), and as long ago as 1907

a boiler 30ft. long by 9ft. in diameter, 230lbs. working

pressure, was made from 9 pieces of steel only: 3 shell

plates, 2 end plates, and 4 flue plates (2 only in each

flue), a feat which had previously never been

accomplished, but of which many thousands are now at

work throughout the world. There is a battery of 56 of

this type in Japan.

In this department also is produced

multi-tubular, Cornish, and vertical boilers in great

quantities, many of which can be found in India, where

the firm has its own staff and offices, as also in

Australia and other parts of the World. |

|

The Lancashire Boiler Shop. |

A boiler built in 1908 from only 3

plates, which has worked for 19 years without giving the

least trouble and steams daily at 230 lbs. pressure. |

|

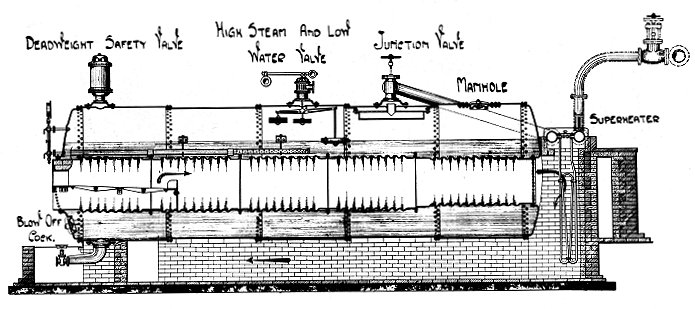

A dish-end boiler with corrugated

flues. |

12 boilers with dished ends and

corrugated flues, suitable for 160 lbs. per square inch

working pressure. Used by the South African mines. |

| Water Tube Boilers - have been more

particularly developed since 1903, and have now

become a very important section of the firm's

productions. They embrace 4 distinct types,

particularly "The John Thompson" patent vertical

straight tube type, of which hundreds are now

working, there being upwards of 100 in Australia

alone, for pressures up to 350lbs. per square inch.

The firm's manufactures include their own stokers,

superheaters, steam piping, chimneys, and water

softening plant. They also erect and carry out

contracts for the whole boiler house station,

including the brickwork of the boiler house itself,

with brick or steel chimneys as may be desired. |

|

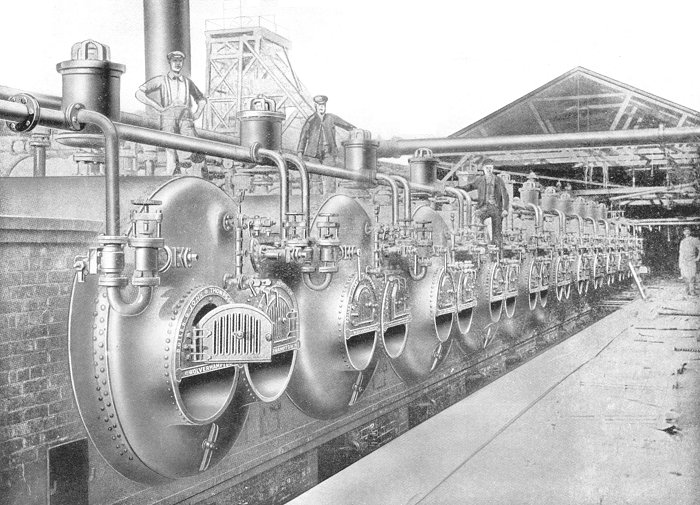

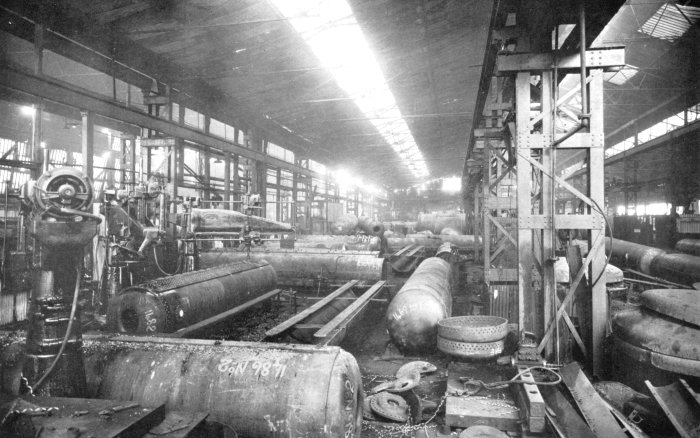

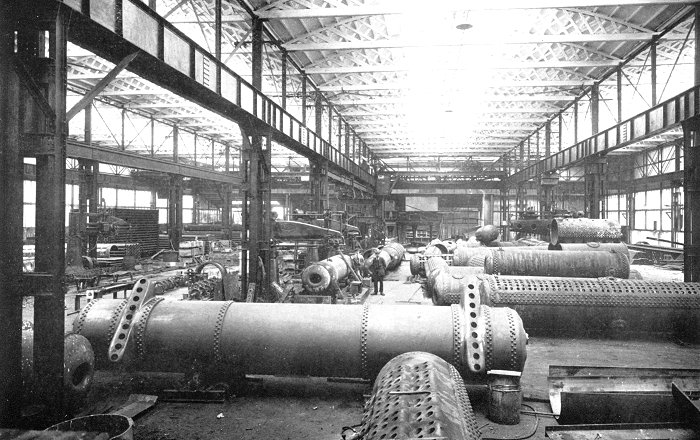

Part of the Water Tube Boiler

Shop. |

|

Part of the Water Tube Boiler

Shop. |

|

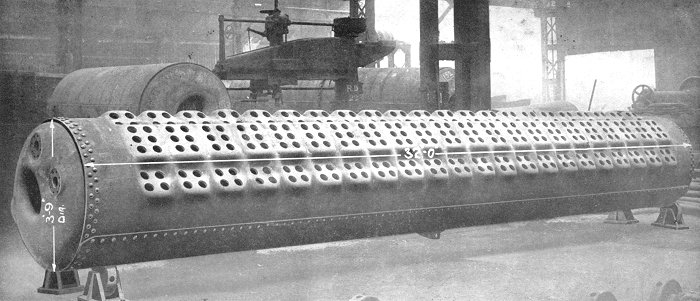

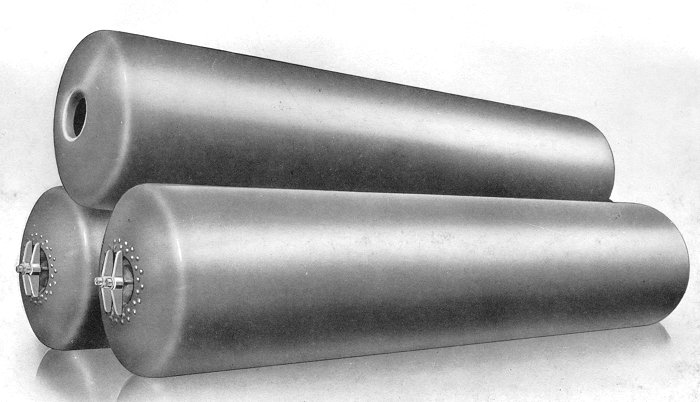

A steam drum, 44 tubes wide, 7

tubes deep, tube plate 1¼

inches thick, diameter 3 ft. 9 inches, 32 feet long. |

|

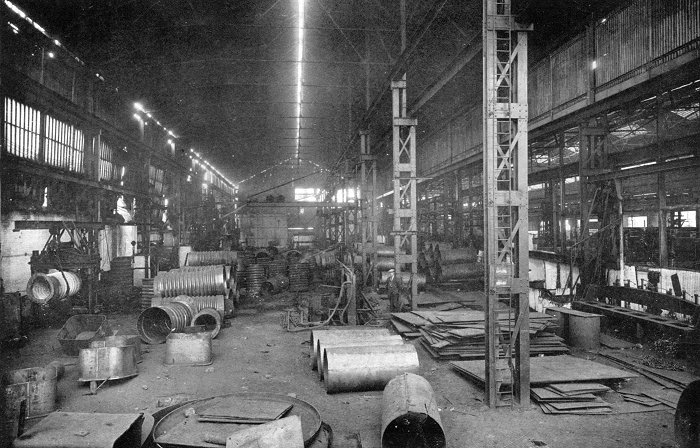

The Corrugated Furnace Shop.

The Corrugated Furnace Shop. |

|

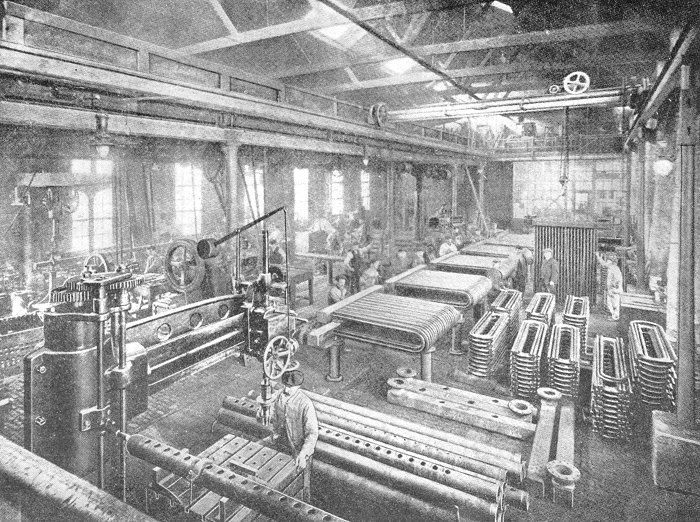

The Superheater Erecting Shop. |

|

Special mention should be made of

the Australian Brown Coal Electricity Plant in Victoria,

operated by 12 of the largest water tube boilers in the

southern hemisphere, each of which are equal to an

evaporation of over 100,000lbs. per hour.

Water Softening Company - The "Kennicott"

water softeners are recognised as the best on the

market, and have been in use for many years and in the

largest units, both for town, railway, industrial and

household supplies, in all parts of the world, including

the United States.

Structural Works, Dudley - have

some 250 men and are now producing a great variety of

work (Welded and Rivetted) also chemical works and oil

storage plants.

Motor Pressings - has its own very

extensive works for cars and lorry frames, wings and

bonnet work for cars, and is equipped with very heavy

hydraulic presses, 25 to 28ft. long, and American power

presses.

It is interesting to remark that

the Frame for the Sunbeam car which achieved the world's

record of 207 miles per hour, was made at these works. |

|

The world land speed record

breaking 1,000hp. Sunbeam car, during chassis erection. |

|

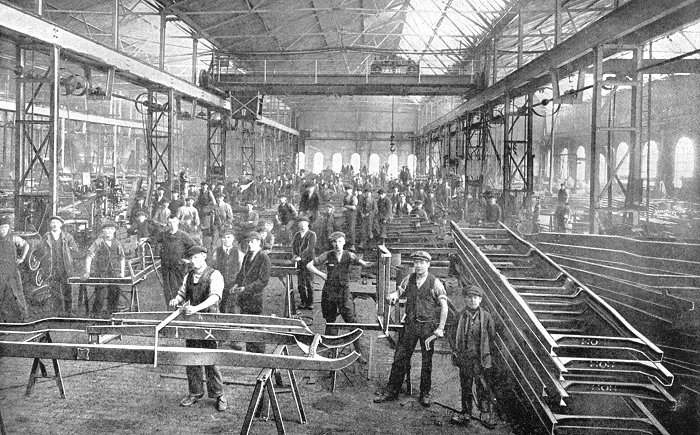

The Frame Erecting Department at

the Motor Pressings Works. |

|

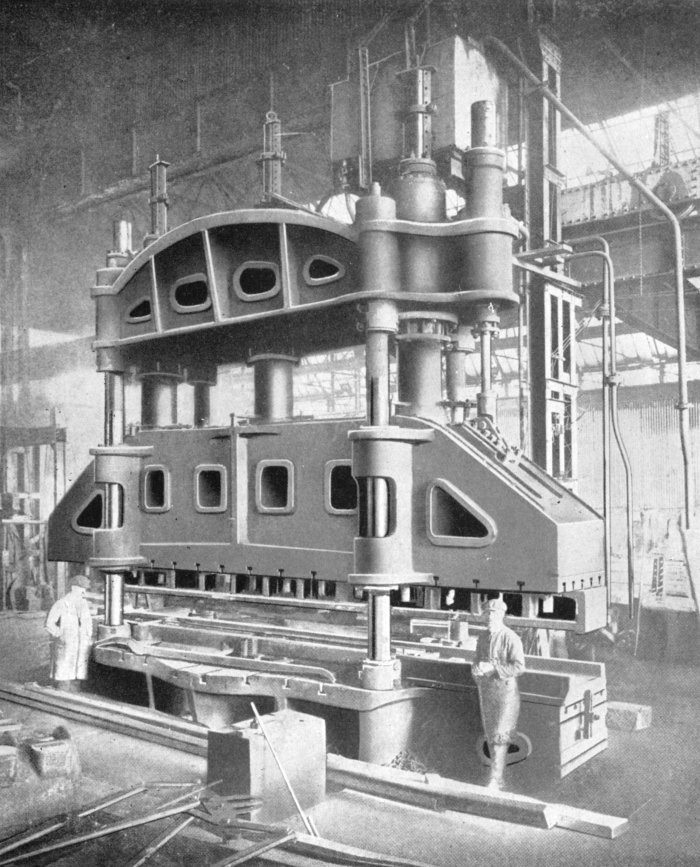

One of the large hydraulic

presses, 28 feet long. |

|

Window Frames - This is a

separate company employing some 250 men on steel window

frames.

The company also has its own staff

overseas, including a subsidiary company with main

offices in Melbourne and Sydney (Australia), also

Calcutta (India). |

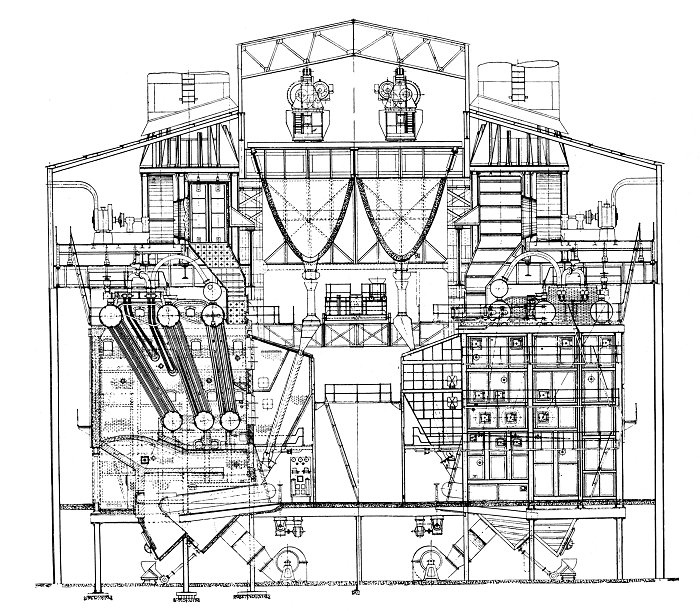

The patent vertical straight tube

'Alpha' boiler in a boiler plant, consisting of 12

boilers, each having 14,500 square feet of heating

surface, 260 lbs. working pressure, complete with

superheaters, stokers, fans, chimneys and boiler house

plant. Supplied to Yallourn Power Station, State

Electricity Commission of Victoria, Melbourne,

Australia. |

|

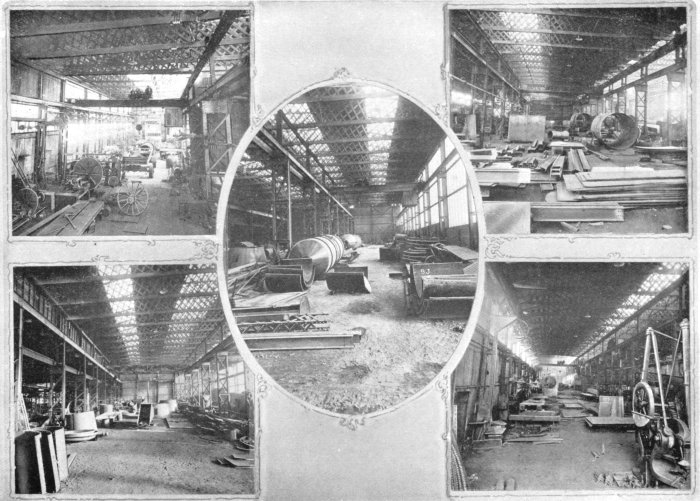

The interior of the Dudley

factory. |

|

Welded Gas Receivers, 20 ft. long,

4 feet 6 inches in diameter. Test pressure 275 lbs. per

square inch. |

|

Staff and Workpeople - The

staff and workpeople have had first consideration.

Facilities were granted for the purchase of shares first

to the staff and afterwards to the workpeople, and

during the past 14 years some 700 of these have been

shareholders, and who at the present time hold one-fifth

of all the shares of the company, preference and

ordinary, the remainder being held entirely by the four

governing directors. The shares have been paid for by

savings from wages and salaries week by week or month by

month, and from the staff and workpeople, directors have

been elected to sit on the boards.

There has also been established at

the firm's expense, special funds for unemployment,

accident, benevolent, and an old age pension scheme.

About 40 men can claim to have been regularly employed

between 40 and 60 years, and a further 150 for 30 years

and over. In many instances there are three generations

of families working in different departments,

consequently the relationship between employers and

employees is of the happiest nature, which justifies the

firm in saying that if only such schemes were adopted

more extensively, there would be almost an end to the

serious troubles which have gone so far to upset

conditions in this good old country.

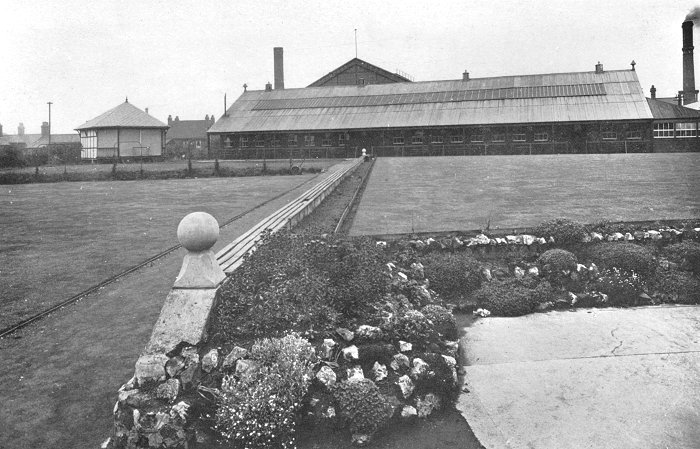

Sports and welfare has not been

neglected; the workpeople have their own athletic

ground, tennis courts (five) with large pavilion;

canteen, adjacent to which are two bowling greens, and

bandstand, these latter directly adjoining the works.

They also have their own band which

elected to serve as the band of the 6th Battalion South

Staffordshire Regiment; male voice choir, football,

tennis, bowling, fishing and poultry clubs. |

|

An employees' children's party. |

|

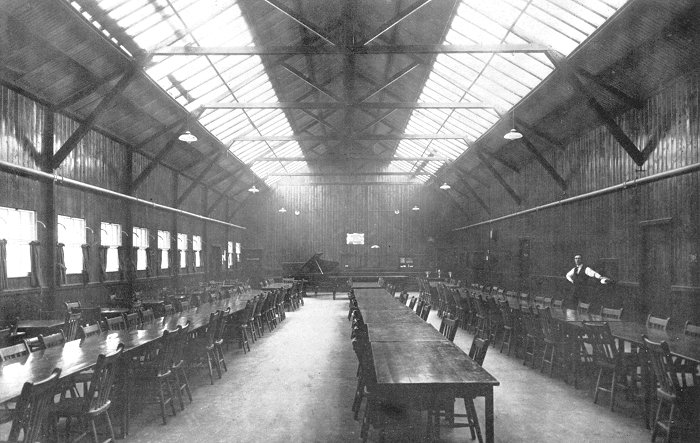

Works Canteen, seating 400 people. |

|

Canteen, bandstand and bowling

green. |

|

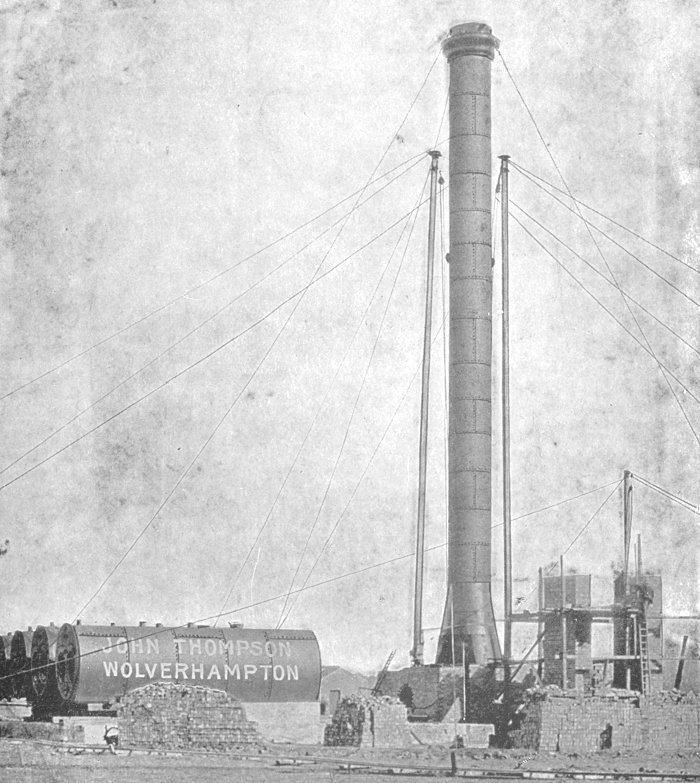

Self supporting steel chimney, 110

feet high by 5 ft. 9 inches in diameter, in course of

erection. |

|

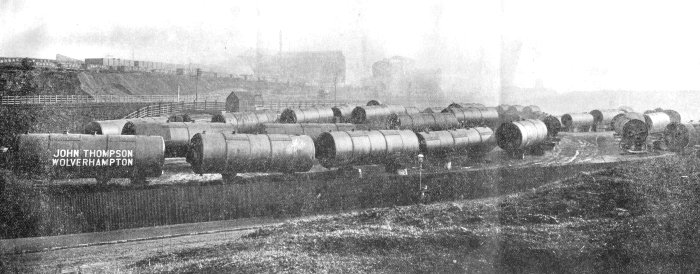

Completed boilers awaiting

transportation. |

|

Return to

The Menu |

|