| Hydraulics & Pneumatics Limited manufactured a wide

range of industrial and marine hydraulic and pneumatic

equipment, and valves for liquids and gases. The

valves, known as 'Fullway' valves were available in a

wide range of sizes to suit many applications. They

could also be remotely controlled and so were suitable

for automatic systems.

They had many advantages over the competition. They

offered a smooth full-way passage that avoided the

possibility of turbulence, and could operate without

leakage, in either direction of flow. They required no

lubrication, which could contaminate the media, had no

wearing surfaces, so they were reliable for long

periods, and needed little attention. The smaller valves

could operate at pressures of up to 5,000p.s.i. They

were suitable for viscous or gritty liquids, or high

vacuum, and could work over the wide temperature range

of -80oF to +400oF. |

|

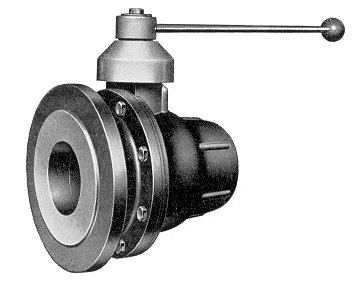

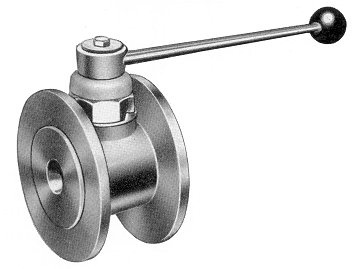

An SFFK ball valve. |

SFFK ball valves were fitted with a spherical plug

shut-off unit and provided a straight through circular

passage with excellent flow characteristics.

Turbulence was eliminated because the medium passed,

as if through a smooth pipe, and a leak-tight seal was

given in either direction of flow.

The valve was fitted with 90o rotational

stops and consisted of a forged steel body with an

anodised aluminium alloy spherical plug, and Perbunan

seals. |

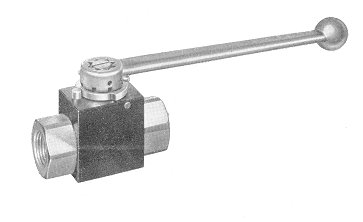

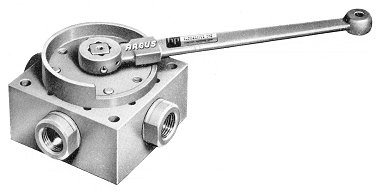

| BK ball valves, like the SFFK valves, had the same

excellent flow characteristics and freedom from

turbulence. Sealing of the spherical plug was ensured by

sealing rings under pressure, which gave a leak-tight

seal in either direction of flow. The body and

connections were of rust-proofed steel, the spherical

plug was made of brass, and the seals were made of

Perbunan. |

A BK ball valve. |

|

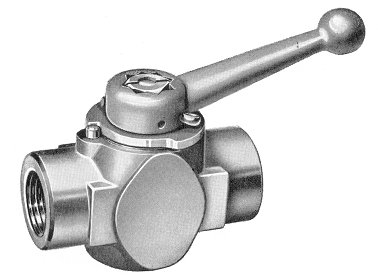

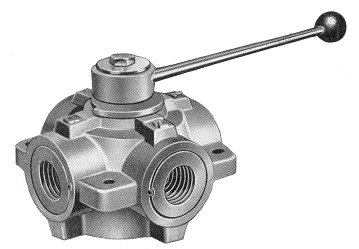

A low pressure NK ball valve. |

The NK valve was fitted with a spherical plug

shut off unit offering excellent flow

characteristics and freedom from turbulence. Sealing

was ensured by an annular sealing ring whose contact

pressure increased as the operating pressure rose.

This provided a tight seal in both directions of

flow. The valve operated over a rotation of 90o.

The body and interior parts were made of brass and

the seals were of Perbunan or Polyamide. |

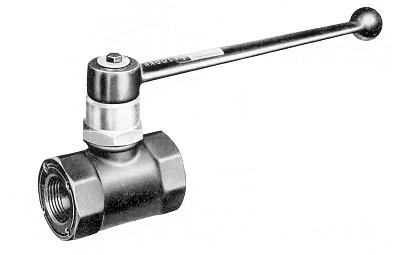

| Like the other valves in the range the MK was fitted

with a spherical plug shut off unit and so had the same

flow characteristics and freedom from turbulence as the

other models. Sealing of the spherical plug was ensured

by sealing rings under pressure, which gave a leak-tight

seal in either direction of flow. The spherical plug

had a hard chromium plated surface and the seals were

made of Perbunan, Polyamide or Teflon. |

A screwed ball -valve type MK. |

|

A flanged ball-valve type KFK. |

The valve had the same excellent flow and operating

characteristics as the other models.

The KFK valve was shorter, and mounted between two

large pipe flanges. It could handle very high pressures

of up to 4,250p.s.i.

The internal pipe diameter was between

½ inch and 2 inches. The

body was made of steel and the plug of chromed steel or

chromed cast iron. The seals were of Perbunan,

Polyamide or Teflon. |

| BKM valves were 3 or 4 way valves which provided a

tight seal in all directions of flow. The operating

pressure was up to 4,250p.s.i. depending upon size, but

they were not suitable for use with gases or vacuum.

They had a forged steel, black anodised body, a bronze

annular piston and stainless steel ball-plug. The seal

rings were made of Teflon. |

A BKM Multi-Way valve. |

|

An MW3 3 Way Valve. |

Fullway 3 way valves were fitted with a spherical

plug shut off and control unit, and had 'T' or 'L'

ports. They were ideal for use with oil or water up to a

pressure of 3,550p.s.i. The smaller sizes had a

wrought steel body, whereas the larger models had a

malleable cast iron body. The interior parts were made

of chromium plated brass and the seals were made of

Perbunan or Polyamide. |

| H & P produced their own high pressure seals up to a

diameter of 6 inches. They were originally developed for

the aircraft industry and worked without backing rings

up to a pressure of 5,000p.s.i. They were also suitable

for use in hydraulic systems. Many of the rings were

made of P.T.F.E. although they were available in a range

of materials. |

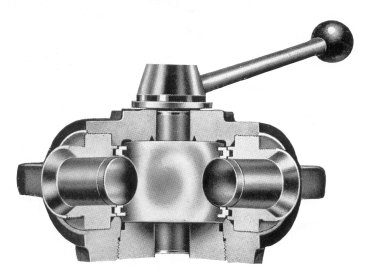

The inner workings of a Fullway

multi-way valve. |

|

A power operated remote control

for Fullway valves. |

The H & P remote control was designed to operate the

whole range of Fullway valves. It consisted of a

double-acting hydraulic cylinder that was attached to

the pipework by two 'U' bolts.

The distance between the valve and the 'U' bolts could

be adjusted to endure that the valve fully opened and

closed. |

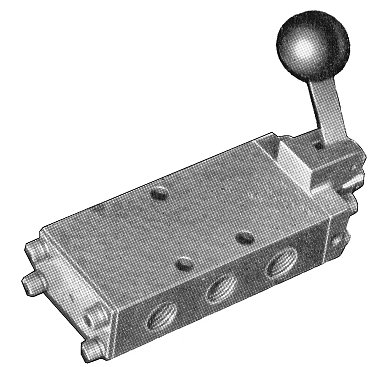

| Several different types of control valve were

produced to operate the remote controls. The one

opposite is a simple hand-operated valve. |

|

|

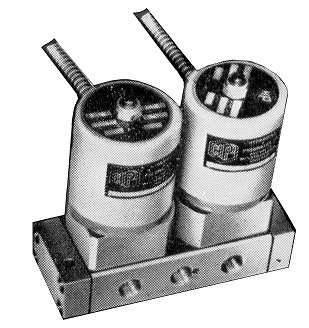

More complex or automatic control systems for the

remote controls could use solenoid valves. The

photograph shows a double H & P solenoid operated valve. |

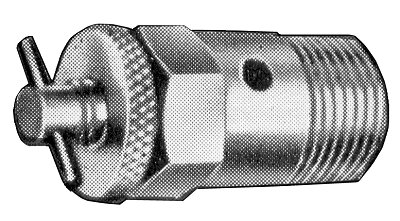

| Speed controls, such as the one opposite were

produced to control the time taken for the remote

control to open or close a valve. |

|

Large diameter Fullway valves in use in a tanker

wagon loading

station. |

|

Several remote controls in

operation. |

The Fullway valve system was extremely

sophisticated, and complex systems could easily be

developed. Large installations could be remotely

controlled from a central point, an important

feature that found uses in many industries including

shipping.

|

|

Read

about H & P's

marine products |

I would like to thank Derek Beddows

for his help in producing this section. |

|

Return to

the Turner

Manufacturing Co. |

|