| The photographs below show just a few of the vast

number of products that were made by the company. Their

range of diesel engines, hydraulic and pneumatic

products was very large. I hope the few images that are

included below will give an idea of Turner's engineering

expertise. |

|

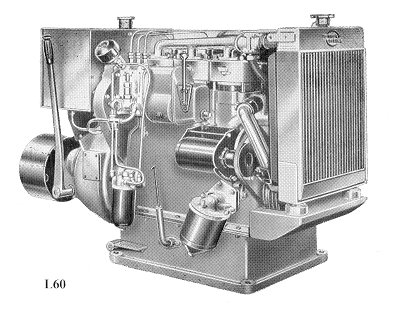

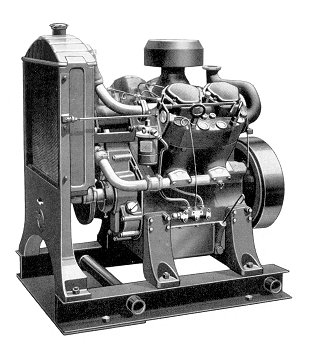

A Turner 2 stroke,

supercharged, industrial diesel engine type L60. |

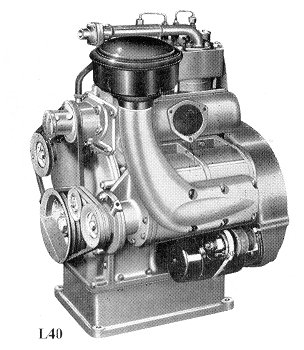

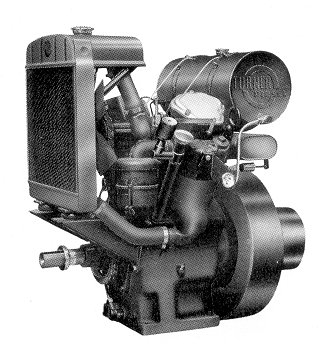

A Turner 2 stroke,

supercharged, industrial diesel engine type L40.

Suitable for generator sets, compressor

sets, pumping sets, welding equipment, power packs, and

winches etc. |

|

|

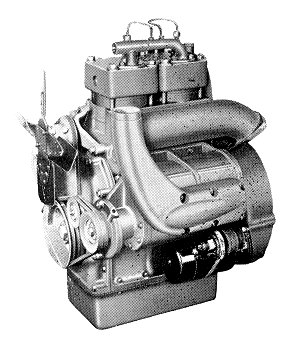

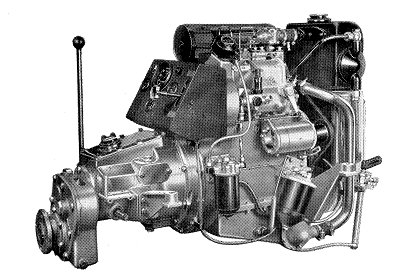

A Turner 2 stroke, automotive

diesel engine type L40.

It was designed for use in light and medium weight

commercial and passenger vehicles such as Land Rovers,

industrial taxis, agricultural tractors and harvesting

machines etc.

|

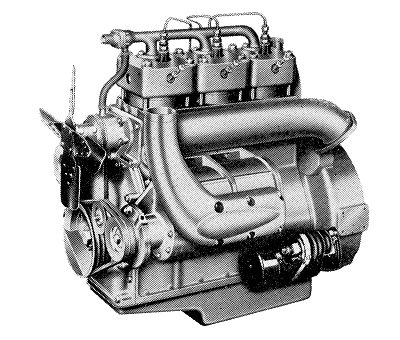

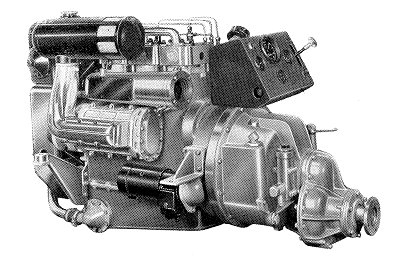

| A Turner 2 stroke, automotive

diesel engine type L60.

It developed 56b.h.p. at 2,800r.p.m., and had a maximum

speed of 3,150r.p.m. It could deliver a maximum torque

of 15.78 M.Kg. |

|

|

A Turner 4V95 four cylinder,

30 to 36hp. It was developed for the 'Yeoman of England'

agricultural tractor but was also available in a variety

of forms. |

| The smaller Turner

2V95 which like its bigger brother was available in a

number of forms. Tank

cooling or radiator cooling versions were available as

was a radiator cooled version with a clutch. |

|

|

A Turner 'Sea Princess' 2

stroke, supercharged marine unit.

They were the lightest marine

units in their power class in the world. |

The larger Turner 'Sea Prince'

2 stroke, supercharged marine unit. |

|

|

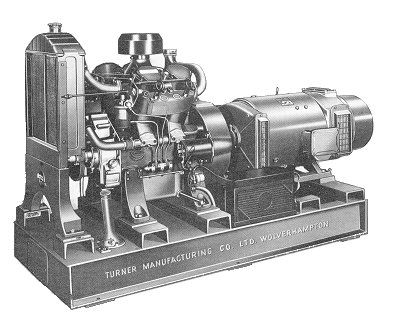

Turner also produced diesel

generator sets.

The one opposite could produce

18.5kW,(23kVA). They were available as 3 phase or single

phase units.

The 3 phase units supplied

either 400 volts or 230 volts and the single phase unit

supplied 110volts. |

|

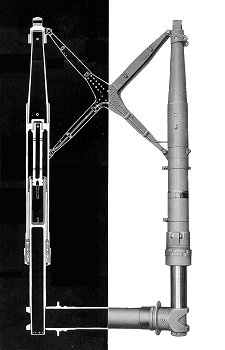

Turner pneumatic aircraft

undercarriages. The units

were both light and extremely simple, and were used on

many well-known aircraft.

Energy was absorbed during both

compression and extension of the shock absorber by the

passage of air through the throttling holes. |

|

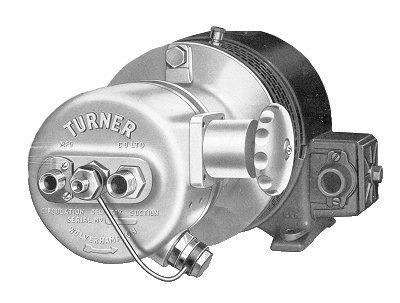

| Turner also produced a wide

range of rotary oil pumps for use in hydraulic systems.

They were used in many applications such as machine

tools, and jacks, or any system that required hydraulic

power. |

|

|

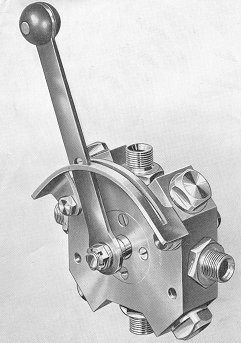

The photograph opposite shows

a Turner selector valve for use with their hydraulic

systems. This particular example has four ports.

Hydraulic equipment was very important to the company,

and large numbers of systems and components were

produced. |

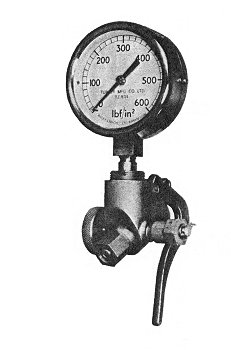

| Turners also manufactured test

equipment for hydraulic systems. The photograph opposite

shows a 772B MK2 Inflation Adaptor, which is a pressure

gauge for attaching to a hydraulic system. |

|

|

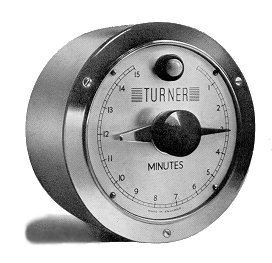

The company also manufactured

interval timers for use in any application where

accurate timing was required. |

| The photograph opposite shows

a Turner air pump which was used for the inflation of

pneumatic aircraft undercarriages. It is one of the many

air pumps that were produced by the company. |

|

An advert from 1956.

| The following article appeared in 'The Engineer', on

13th December, 1946: |

|

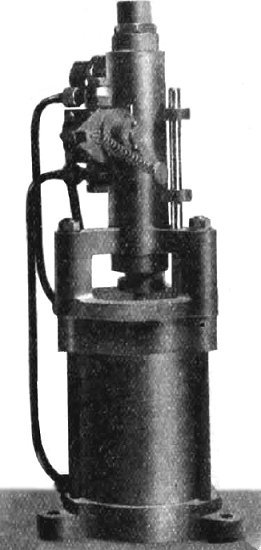

An Air-Operated Hydraulic Pressure Testing Pump

A compact small pump, designed

for use with high pressure hydraulic testing

equipment which is now being made by the Turner

Manufacturing Company, Limited, Villiers Street,

Wolverhampton, is illustrated in the accompanying

engraving. It is designed for coupling directly to

existing factory air lines, and serves as an

intensifier which uses the pressure of the air to

raise the oil or water in the hydraulic system to a

higher pressure. |

|

The pump has two cylinders arranged vertically

in tandem, the pistons in each cylinder being

coupled together by a common connecting rod. The

piston in the lower cylinder is actuated by the

compressed air and it has a considerably larger

surface area than the upper piston.

Air is supplied to the double acting lower

cylinder through a ported rotary valve, which is to

be seen on the side of the upper cylinder in the

illustration. This valve is operated through a push

rod connected to the air piston and projecting

upwards through the cylinder cover. The air valve

spindle is balanced by a spring and is unaffected by

the air pressure. This arrangement avoids any

tendency it might have to stick when being swung

over.

In order to save time when filling the hydraulic

system, the hydraulic inlet and outlet valves have

been designed to lift at relatively low pressures so

that liquid from the mains supply can flow straight

through the pump.

Once the pressure in the system equals that of

the mains supply, the pump begins forcing the

pressure up to the required figure. The pump

operates continuously until the maximum pressure is

reached when it stops automatically. |

|

It holds the pressure

indefinitely without any loss, but if the hydraulic

pressure is lowered during the test the pump

restarts automatically. An air-reducing valve which

can be fitted to the unit permits an infinite

variation of air pressure up to the maximum of the

mains supply.

Pumps are made in two types,

each working with an air supply of 80 lb per square

inch. One pump delivers liquid at 750 lb per square

inch at a rate of 4.5 cubic inches per stroke, and

the other at 2,000 lb per square inch at 1.7 cubic

inches per stroke. Higher air pressures of up to 100

lb per square inch may be used to give

correspondingly increased hydraulic pressures. |

|

|

Return to

the

previous page |

|