This is an account of how mill

rolls were produced. On the following pages (linked at the

bottom of this page) are photographs from a book produced by

Perry's which illustrate this process. These photographs

are referred to by their numbers in this account.

The production process

can be said to start with the making of the patterns (wooden

replicas of the necks and wobblers of the rolls) and sweeps (for

grain rolls) (See photographs 1,2 and 3). Sweeps were

profiled wooden boards used for moulding rolls, which were cast

with their profiles.

The neck and wobbler

patterns were placed in moulding boxes and sand rammed hard

around them. (See photographs 4 and 5) When all the sand

had been added the patterns would be withdrawn leaving a neck

and wobbler shaped void into which the metal would be cast when

the final mould assembly took place.

The method of making

grain rolls using sweeps is described alongside photograph 3.

Once the mould had been

made and assembled the melting process could begin. The furnaces

were charged with a mixture of lumps of scrap roll (worn out

rolls bought back from the customer) (See photograph 8),

surplus metal from previous casts, the heads and gates from

previous casts, and pig iron.

The weights and chemical

composition of each of these various components of the

charge were established and a great deal of careful

calculation done by the metallurgists to ensure that the mix was

such as to provide a chemical composition as near as possible to

that demanded by the nature of the rolls being cast. (See

photograph 31)

Chemical constituents

included carbon, silicon, manganese, nickel and chromium. It was

necessary to calculate the charge so that the minimum of

alloying additives (which were expensive) would need to be added

to the furnace to obtain the correct composition.

The furnaces were

reverbatory furnaces fired by pulverised coal. [A reverbatory

furnace is one in which the fuel is not in direct contact with

the charge, the heat generated by the burning fuel bouncing-

reverberating- from the furnace walls onto the charge.]

Once the furnace was

charged- the furnaces shown had removable tops so that the

charge could be loaded by crane – and the tops replaced, the

pulverised coal was drawn from the silos (see photograph 9)

by a system of pipes to the furnace burners where it was blown

into the furnaces as a jet of coal dust and air.

The coal/air jet was lit

and the heat produced by the burning jet of coal dust and air

heated up the furnace and after a while caused the metal to

melt. The metal would only be tapped from the furnace when it

had reached the desired temperature for the particular metal

composition and roll type. (See photographs 10 and 11)

How long a charge took

to melt and attain the desired temperature depended upon a

variety of considerations: the weight of the charge; the tapping

temperature needed etc., but was certainly several hours. The

furnaces would be fired up early in the morning (perhaps at

around 6.00am) and it might be 1.00pm or 2.00 pm before the

furnace was ready to tap.

The furnace would then

be tapped out as shown in photographs 12 13 and 14 and

cast as shown in photographs 15 and 16.

After casting, the mould

would have to be left for some while (in the case of the large

rolls for perhaps 3 days) to allow the casting to cool

sufficiently to be removed, partly because of the danger and

discomfort to the workers involved and partly because if done

too soon the thermal shock of the cold air on a hot casting

might cause it to fracture.

The moulding boxes and

chills (where used) would be removed by a small gang of men

called “Strippers”, the gate broken off the casting and

the casting lifted by crane to one end of the foundry, when

adherent sand would be removed using a pneumatic chisel and

powered grinders. The man who did this was called the “Dresser”.

The casting would then be transferred to the machine shop for

machining. (See photographs 17 to 30)

Some rolls would have to

be annealed before machining. This involved placing them in gas

fired annealing furnaces and heating them slowly to a

temperature well below the melting point and then allowing them

to cool in a controlled manner over days. The purpose of

annealing was to alter the metal structure by the heating and

cooling process and so make them more resistant to the shocks

which they would encounter when in service in the mills.

The following photographs, which appeared

in the book which Perry's published in 1967, to mark the

modernisation of the plant, give a good idea of how mill rolls

were produced.

|

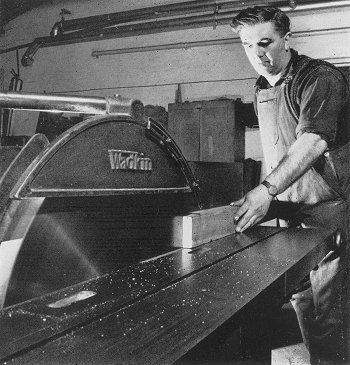

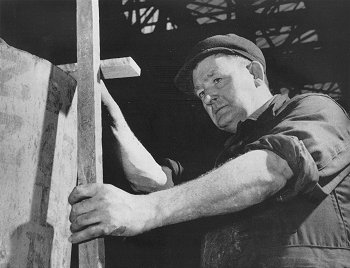

1. Using the circular saw to cut timber for

patterns.

The pattern maker is Roy Miller.

|

|

2. Shows the pattern maker, Roy Miller, checking the

dimensions of a wooden pattern for a roll neck. |

|

|

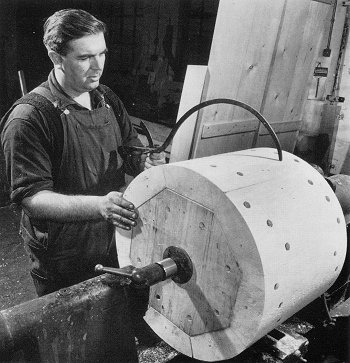

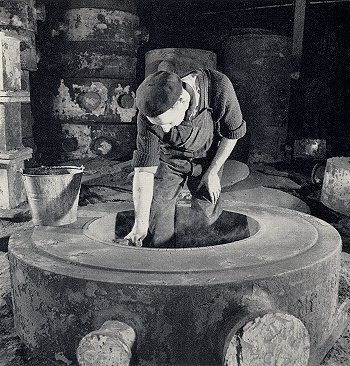

3. Shows Isaiah Wellings beginning to mould a section of a

grain roll. |

|

A grain roll was a

relatively soft sand cast roll, cast with its profile.

Grain rolls were used in the mills for initial rough forming of

steel. The mould was made in sections using a sweep- a wooden

board cut to the profile and size necessary. A moulding box was

placed on a metal base plate on the foundry floor and the sweep

bolted to a rotating central spindle [these are clearly seen in

the photo] Iron bricks (called denseners) were built up and sand

packed between them, the sweep being rotated to ensure that the

correct profile was being maintained. When all the denseners had

been placed a coat of loam (always pronounced “loom”) was

applied by hand. This was a thick paste of sand and various

binders (special clays etc). [In the old days horse manure was

added to the loam mix to give added binding power but I cannot

recall this being done during my time]

The sweep would be

rotated again as necessary until the moulder was satisfied that

the correct dimensions and profile had been produced. The mould

section would then be removed and dried in coke fired ovens

[always called stoves] for perhaps two or three nights. Once

dry, the various sections would be brought to the casting pits

and assembled to form the finished mould. |

|

4. Shows the moulder,

Tommy Morris, checking that the pattern for a “wobbler” is correctly

set in the mould before beginning to mould the sand around it.

The wobbler was essentially the means by which the roll was

connected to the mill drive when installed in the mill. [If I

remember right not all rolls had wobblers- some had spade ends (see

photo on page 55 for illustration of spade ends) I think that it was

probably the strip and plate mill rolls which had spade ends rather

than wobblers.] |

|

|

5. Shows the beginning

of the moulding process for the neck of a roll.

The moulder, Walter Jayes,

is checking that the wooden pattern is level and at the correct

height.

|

|

6. Shows a large chill

being sprayed with a carbon black solution. This was to prevent the

molten metal adhering to the chill during casting.

A chill is a cast iron

cylinder of suitable diameter, used to make the mould of the body of

certain kinds of rolls [known as chill rolls] The purpose of the

chill was, as its name rather suggests, to cause very rapid cooling

of the molten metal during casting, producing a very dense metal

structure at the cast surface and imparting a hard-wearing surface

to the body of the roll.

I cannot remember the name of the worker. |

|

|

7. Shows a small chill

being dressed. A slurry of sand and binders was applied with a

brush. Again the purpose was to prevent the molten metal adhering to

the chill during casting.

The chill dresser is Ron

Smith.

|

|

8. Shows the scrap gantry to the rear of the foundry. This

gantry was installed as part of the mid-60s modernisation. |

|

Not seen in the photograph is the breaking pen. This was a

circular enclosure of heavy steel plate (lined I think with

baulks of timber). Scrap rolls would be lifted by the crane into

this breaking hole and then a heavy steel ball dropped from the

crane onto the rolls, thus breaking them into pieces suitable

for charging to the furnaces.

Perry’s prided itself on having very low production scrap rates

so virtually all of the rolls seen in the scrap gantry would

have been worn out ones purchased from the customer for

remelting to make new rolls. |

|

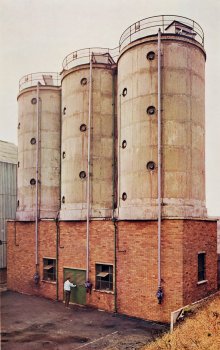

9. Shows the silos

used to store the pulverised fuel which fired the furnaces after the

modernisation.

The coal (ready pulverised)

was delivered by tanker from James Durran of Penistone, Yorks and

pumped into the silos. From the silos it was transferred by pipes to

the furnace burners as needed. |

|

|

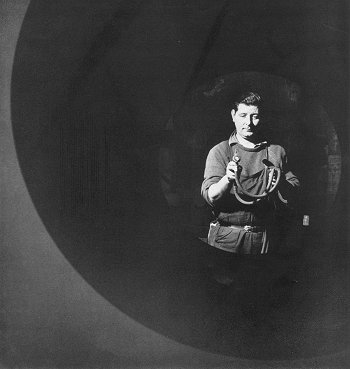

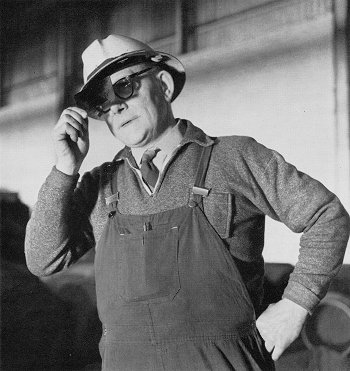

10. Shows the furnace

chargehand, Harold Hall, looking into a furnace through a piece of

blue glass.

Furnacemen of long standing- like Harold -

claimed to be able to judge the temperature of the molten metal in

the furnace nearly as accurately as could be measured by an

instrument, simply by looking at the colour of the metal and

applying their experience. |

|

11. Shows the

temperature of the molten metal (the “bath”) in a furnace being

taken.

Holding the pyrometer is Bill Farrell, Chief Metallurgist. Standing

next to the furnace is Bill Mullinder, furnaceman. |

|

|

The long pole like object is a pyrometer, an instrument

specifically used for measuring molten metal temperatures. The

cable seen trailing from the rear goes to a recorder which

traces the temperatures on a paper chart. |

|

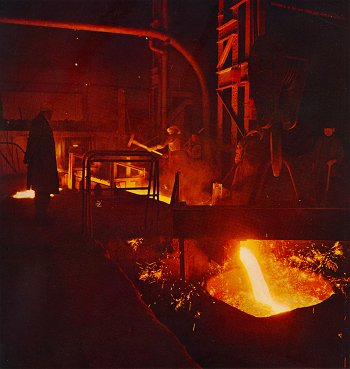

12. Shows one of the

new furnaces (i.e. post the 1960s modernisation) tapping out into a

ladle.

Each furnace had a hole at

the bottom of the base from which the molten metal would run.

Before melting began this hole would be plugged with sand. When the

melt was of the right temperature and composition the crane-held

ladle was dropped into position and the sand plug removed by using a

long pointed steel bar [This was tapping out]. The molten metal was

then free to run from the furnace into the ladle. |

|

The man shown wielding the hammer is driving down the steel

gates in the runner channel to hold back much of the slag which

emerges at the end of the tap-out, while still allowing the

remaining metal to flow into the ladle. [The slag is

lighter than the molten iron so floats on top of the iron in the

furnace- as the last of the molten metal runs out so does the

slag.] |

|

13. Another view of a furnace tapping out into a ladle. |

|

|

14. Another view of a furnace tapping out into a ladle. |

|

15. Shows a roll being

cast.

The rolls were cast standing on end in casting pits. The box into

which the metal is being poured was called the receiver. From there

the molten flowed vertically down through a part of the mould called

the gate [always pronounced “git”] and entered the main body of the

casting from the bottom. |

|

|

Although it cannot be seen from the photos the git was moulded

in such a way that the metal entered the bottom of the roll

mould at a tangent. This caused the metal to spin as it rose up

the mould, sweeping any slag and debris into the centre and

rising to the top. This was so that debris etc would not cause

defects on the face or in the body of the casting. |

|

16. Shows the final

stage of the cast, topping up the head. The ladlemen here are Billy

Elbro (on the left) and Arthur Billingsley.

The head was at the very top of the mould. Its purpose was to

provide a reservoir of metal which would remain molten for longer

than the main body of the roll and so feed metal down as cooling and

contraction took place, thereby eliminating voids in the finished

casting which would have had a very deleterious effect. |

| Exothermic compounds were shovelled onto

the head to help the metal in it stay molten longer.

Casting was one of the most skilful parts of

the roll founding process. There was no question of delivering a

weighed amount of metal to the mould; all was done by judgement

and experience. Clearly the mould had to be filled to the top,

i.e. the head, but equally clearly it was highly undesirable to

put so much metal in that the head overflowed sending quantities

of molten iron over into the casting pit and presenting a real

risk of burns to anyone in the vicinity.

Each cast was controlled by the Foundry

Superintendent or Foreman who (while the metal was being poured

into the receiver) stood on the metal plate shown in front of

the mould (protected from splashes and sparks by a hand held

wooden shield) and watched the metal rise up the mould. When he

judged that there was sufficient metal to fill the mould

including the head (and taking into account the quantity of

molten metal still in the receiver) he would call “Up” to

the ladlemen and they would then swing the ladle back upright,

so stopping any further metal entering. Notwithstanding all the

experience of the Superintendent or Foreman, sometimes he called

“Up” a little too soon and then the head had to be topped up.

This is what seems to be happening in this picture. A large part

of the skill in correctly calling the ”Up” was not simply

judging how much metal had already gone in but how quickly the

ladlemen could swing the ladle upright. This would depend upon

the size of the ladle (a big ladle would move much more slowly

than a small one) and even on the characteristics and strength

of the individual ladlemen. |

|

17. Shows a beam roll

being machined in the machine shop. The machinist is Norman

Willis(?)

A beam roll was used to

impart the H or I section to steel in the mill. A beam roll would be

set vertically in the mill to produce this section. |

|

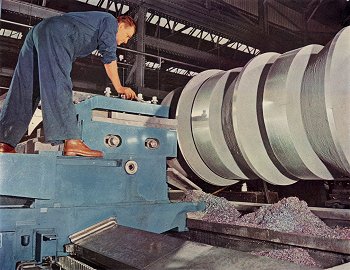

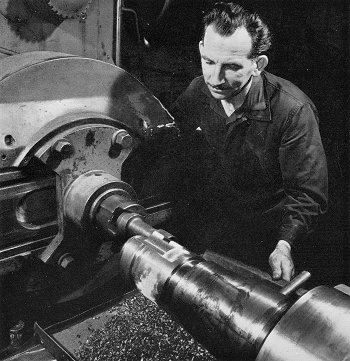

18. Shows a strip mill

or plate mill roll being machined.

I cannot remember the name of the machinist. |

|

|

19. Shows a grain roll being machined. The machinist is Norman

Willis(?). |

|

20. The same, taken from a different angle. |

|

|

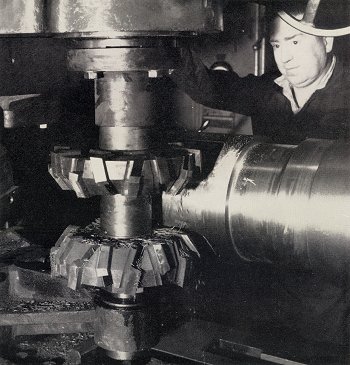

21 A small chill cast roll

being machined. The operation here seems to be machining wobblers.

|

|

22. A small chill cast

roll being machined.

|

|

|

23. What seems to be a plate or strip mill roll being

machined. |

|

24. A small chill cast

roll being machined. I think the machinist is

Cyril Darby. |

|

|

|

|

|

|

Return to

Later

Company History |

|

Return to

the contents |

|

Proceed to

the

Production Process 2 |

|