|

The Chillington Iron Company

and the Chillington Tool Company

The Chillington Iron Works, the

first iron works to be built within the old

Wolverhampton boundary, opened in 1822 on the site

of Stowheath Manor. The works were founded by John

Barker, James Foster, and George Jones. The

company’s products were well known throughout much

of the world for their quality, and the

“Chillington” brand gained a high reputation.

|

|

A map of the old works. |

The ironmaster at the works was

John Barker, a Justice of the Peace, a Sheriff of

the County, and School Superintendent at the Sunday

school at Snow Hill Congregational Church.

John Barker grew up on his father's farm in Cheshire

and came to Wolverhampton after obtaining the

post of assistant in Mr. Warner's drapers shop in

High Green. |

| He went into business with George Jones and they

joined forces with banker James Foster to form the

company. Mr. Foster provided most of the capital and

George Jones the business experience.

Barker was clear headed and strong

willed, and very industrious. He died in 1852 and

his two sons inherited his share in the business.

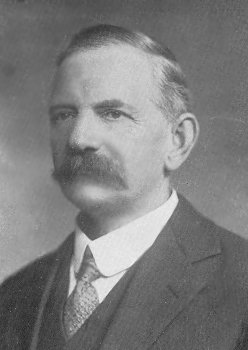

James Foster was well known for his large

manufacturing works at Stourbridge; Foster, Rastrick

and Company, and also his iron works; John Bradley

and Company, also at Stourbridge. He was born in

1786 and became a successful banker. He lived at

Stourton Castle. |

John Barker. |

|

James Foster. |

The plant for the works was

designed and supplied by John Rastrick who had

joined forces with James Foster in 1816 to form

Foster, Rastrick and Company, the large

manufacturing concern at Stourbridge. They became

well known for their work on early railways and

built a few locomotives including the Agenoria, and

the Stourbridge Lion; the first steam locomotive to

run in North America.

James Foster died in 1853. He

never married and his estate passed into the hands

of his nephew William Orme Foster. |

| The site of Chillington Works, about a quarter of a

mile to the east of the canal, had its own coal and

iron ore mines, furnaces, rolling mills and

foundries. The works were connected to the canal by Chillington Basin. The old Stowheath Manor had a

moat, part of which still existed when the works

were built. It consisted of a large pool, 100ft.

long and 75ft. wide. Waste water from the steam

plant was fed into the pool. The company greatly

benefitted from the coming of the railways. On 9th

March, 1836, an order was received from the Grand

Junction Railway for 500 tons of rails and chairs.

In 1839 there were 4

blast furnaces in operation, each producing around

80 tons of iron per week. The total production in

1839 was 16,661 tons. The furnaces used a cold

blast.

John Barker’s sons George and

Thomas eventually purchased the interests of the

partners and extended the works. They leased 200

acres of land at Bentley, Darlaston where they

opened mines and set-up several blast furnaces. They

also purchased the Capponfield Iron Works at

Bilston, and Lea Brook Iron Works at Wednesbury. In

1872 the brothers transferred their properties to a

joint stock company and ran it as managing

directors. By 1873 the company had 95 puddling

furnaces, and 6 mills and forges, with the hammers

working at 10 blows a minute. They also had 6

blast furnaces working night and day at Wolverhampton, and 3 at Bilston.

At Chillington Colliery the company had around 100 shafts that were sunk for

the mining of coal and iron ore. They were

eventually closed due to a dispute with a

neighbouring mining company over the pumping out of

water, which resulted in the pumps being turned off,

and the flooding of the pits.

|

The location of Chillington Colliery which

covered a large area.

|

|

|

|

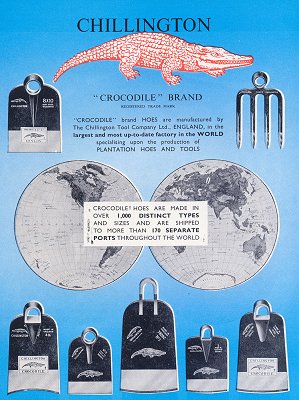

Two adverts

from 1873. |

| The company was hit hard by the

recession in the 1870s and ran for several years at

a loss. As a result serious consideration was given

to a change of direction. The minute book of the

Iron Works Board includes a reference dated 20th

April, 1876 to the “Desirability or otherwise of

taking up the edge tool trade” A further minute of

27th July, 1876 reports that “The

erection of the Edge Tool and Horse Shoe Works has

commenced”. |

In its earlier years the company produced mainly

horse shoes and became known as the largest maker of

hand-made horse shoes in the world.

The shoes were produced under the brand name “King

Of The Road”. The making of horse shoes by hand

required considerable skill and was very arduous. |

The location of the works and

the company's canal basin. |

The tool works superimposed on

a map of the iron works.

|

An old advert. |

It became increasingly difficult to find

sufficient smiths to meet the growing world demand,

and as the demand for hoes and other edge tools

increased, horse shoes were phased out.

The company decided to concentrate on the

manufacture of lighter edge tools such as hoes, and

would soon claim to be the largest manufacturer of

hoes in the world. The tools were sold under the

“Crocodile” brand name and included axes, forks,

shovels and spades, most of which were exported.

The Chillington Tool Company

Limited was formed in 1892 under the direction of

John William Hunt. |

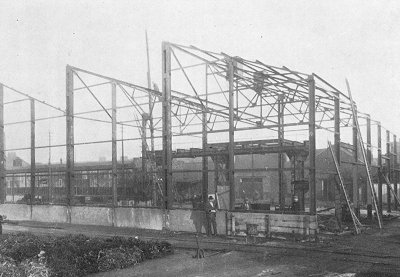

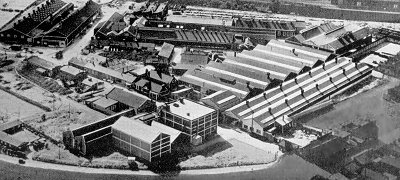

| The tool works soon covered a much larger area

than the old iron works. The buildings were

greatly extended in the 1920s and included a new

up-to-date forging department. |

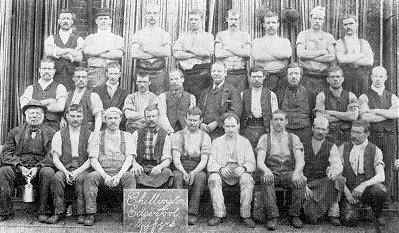

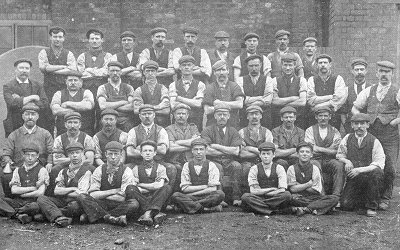

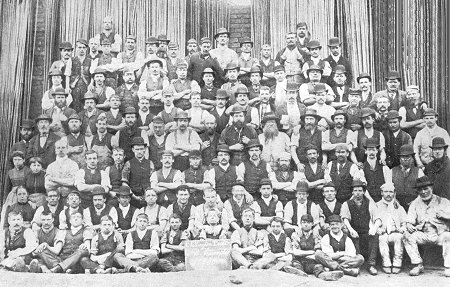

A group of workers from 1888. |

| There were forges, fitting shops, polishing

shops, an emery wheeling department, mill

department, stores, a packing department, a

laboratory, and a metallurgical department.

The works office included the wages department,

the buying department, and the drawing office. There

were also up-to-date toilets with washing basins,

hot and cold water, liquid soap, nailbrushes, and a

plentiful supply of clean, dry towels.

In the early 1920s the fitting shop was used for

the building of gas and oil furnaces. |

|

|

An advert from 1892. |

|

The Warehouse Department

in 1901. Left to right:

Back row - Tom Hitch, Sarah Booth, George Heath,

Ethel Jackson, Joe Green, Eliza Steele, Sidney

Monckton, Dave Lavell,

W. Porter and Rose the dog.

Front row - Sarah Pritchard, Eliza Pritchard, Lily

Chinn, Arthur Parkes, Minnie Jackson, Harriett

Rogers, and Esther Bodley. |

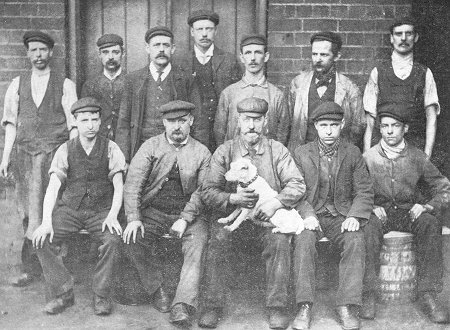

| The grinders

and polishers in 1903. |

|

|

|

The engineering staff in 1903. |

Left to right:

Back row - J. Gandy,

A. Fisher, J. Delve,

J. Halfpenny,

W. Thomas, J. Brown, and H. Webb.

Front row - T. Gandy, G.

Fisher, J. Hopkins, W. Fisher, and

J. Vincent. |

Factory workers in 1888.

Mr. J. W. Hunt's 60th birthday

celebrations at the Agricultural Hall in 1904.

Another view of Mr. Hunt's birthday

celebrations in 1904.

|

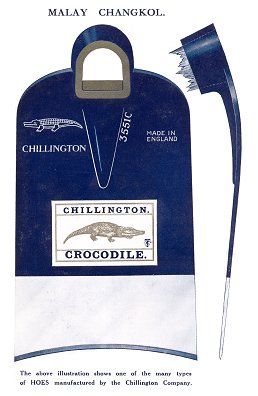

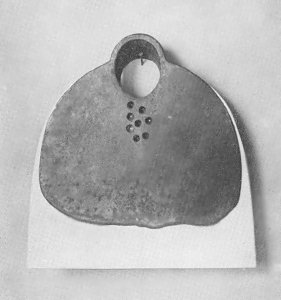

One of the many types of

hoe that were manufactured by the company. |

| An old Chillington hoe

found in the West Indies in 1930 after 12 years of

use.

The white background shows

the original size of the hoe. |

|

| In 1908 a fire broke out at the works one Sunday

morning, but unfortunately the employees were caught

without any effective means of fighting it. As a

result the company's Fire Brigade was formed. Initially the

equipment consisted of 6 lengths of hose and a wheel

valve to connect to the pump. Over the years the

equipment improved and 6 of the members, Chief

Officer H. W. Hunt, 1st Officer G. A. Fisher, 2nd

Officer S. Hopton, Engineer W. Thomas, and Firemen

J. Caddick and A. Adey obtained long service medals

from the National Fire Brigade Union. |

|

Sports and Social Activities

The company had a thriving

sports and social club known as "The Working

Men's Club and

Institute". There were many sports teams including a

thriving football team who played in the local

football league, the works league, and the J. W.

Hunt Cup, named after one of the company's founders.

There were tennis teams, athletics teams, and an

angling team who played for the Chillington

Challenge Cup, and a bowling team who played in the

Chillington Works Bowling Championship.

|

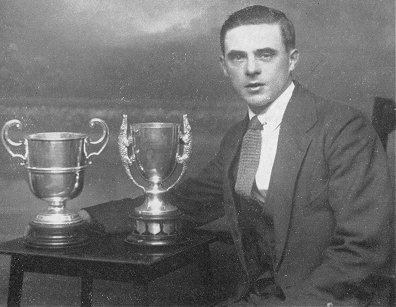

Mr. George Surplice, president

of the Club and Institute in 1929. |

Other activities were provided

by the camera club, the thrift club and the

horticultural society. Whist drives and dances were

also held at the institute, and the fancy dress

carnival dance became one of the highlights of the

social calendar. An annual outing would also be

organised. The many dances were used to raise

funds to pay for the club's activities, and for

donations to local charities. |

The 1927 Fancy Dress Ball.

In 1928 the football teams in

the Wolverhampton and District Works Sports

Association League were:

|

Division 1 |

|

Division 2 |

| Chillington 'A' Team |

|

Chillington 'B' Team |

| Sunbeam |

|

Sankeys |

| Rubery Owen |

|

Weldless Tube |

| Perks and Sons |

|

Jenks and Cattell |

| Harpers |

|

Great Western |

| Palethorpes |

|

Motor Pressings |

| Great Western |

|

Palethorpes |

| Weldless Tube |

|

Sunbeamland |

|

|

|

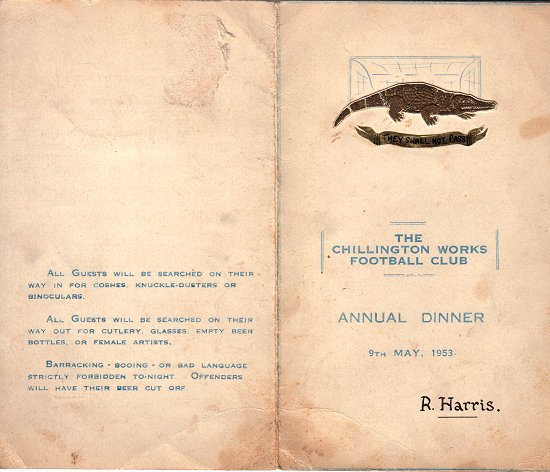

A menu from 1953.

Courtesy of Tina Harper whose father played-for and

ran the football team at the time. |

|

The inside of the 1953 menu.

Courtesy of Tina Harper. |

|

Louis Ward from the

Warehouse Department who played for the 'A' Bowling

Team and became the best bowler in the whole of the

Works League in 1928.

His awards included the Plant

Cup and Gold Medal for the Works League Individual

Men's Competition when he beat 175 other entrants.

He also came first in the Merit Competition, beating

J. Whitehouse of Sunbeam 21 to 11. |

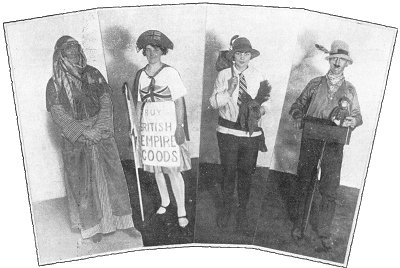

| The prize winners in the

Fancy Dress Carnival held in 1928.

Left to right:

Mr. C. Walker, Mrs. C.

Walker, Miss D. Taylor, and

Mr. W. Crowe. |

|

| The founder of the tool company, Mr. John

William Hunt died on 10th December, 1925 at his home

Maycroft, Ash Hill, Compton. He was 81 years of age.

Some of the employees

in the 1920s |

|

Mr. Sidney Monckton

entered the company in 1889 as a warehouseman. In

1911 he took charge of the Shoe Turning Department

where he remained until 1918. afterwards he was in

charge of the General Stores.

During the First World War he

became chairman of the Chillington War Savings

Association and afterwards became secretary of the

Angling Club. |

| Mr. Aaron Heath began at

the works in 1887 as a horse shoe striker for Harry

Johnson, and later for Jack Baxter, then Joe Miller.

After a couple of years making shoes, a reduction in

demand meant that he had to return to striking. He

struck for Pat Powell, Jimmie Kerrigan and later

Arthur Wilden. After a few years he returned to shoe

making until 1917 when he began tool setting in the

Forge. He was proud

to have never drawn a day's sick pay. His two

brothers, four stepsons and his daughter all worked

for the company. |

|

|

Mr. Jack Hewins started at

Chillington in 1885 as a boy of 14. He began his

working life heating hand-made ploughs for Dave

Smith. He then moved to the Polishing Shop to become

a polisher under Jesse Broome.

During the First World War he

became a charge hand working night shifts at a time

when much of the production consisted of entrenching

tools. After the war he continued as a charge hand

but worked on the day shift.

His two sons, two

daughters, brother and nephew also worked at

Chillington. |

| Mr. Tom Edge started work

in 1890 at the age of 13 as a heater for H.

Cartwright, a mould steeler. After some time

striking on horse shoes, and another stretch in the

Steeling Department he became a mould steeler. After

many years he became a stamper.

His 3 sons, stepson, and

daughter-in-law also worked at Chillington. |

|

|

Mr. Harry Wilden started at Chillington in

1883 at the age of 14. He began his career

working as a heater for Harry Cartwright and was

promoted to striking before he was 16. He later

heated for Alf Heath and then joined his brother

in the Shovel Shop, where he worked for many

years. His son Harry Wilden junior and his

daughter also worked at Chillington. |

| Mr. Tom Hunt was the Works Engineer. He became

well known as a song writer and had many

compositions to his credit.

One of his songs "The Baby Tank", written in

France during the First World War, became well known

in several countries. It became quite popular and

resulted in the sale of about half a million

records. |

|

|

Mr. Fred Roberts started

at the works in 1889 at the age of 14 as a heater.

He later worked with his brother Tom, then started

striking for Dave Smith on odd work.

His daughter Tilly worked in

the Warehouse and his son worked in the Mill. |

| Mr. John Dutton worked for

many years as a wet grinder. Unfortunately the dust

and fine particles caught up with him and he had to

retire early on a pension at the age of 46. He was

one of the last wet grinders because that type of

grinding was abolished. After a long and trying

illness he died at the age of 50. |

|

|

Mr. David Potts worked at

Chillington for 32 years as a plater. His son Albert

also joined the company as a plater, and his other

son Dave worked in the Mill. |

| Ted Bradley started work for the company in 1989

at the age of 13. He began working as a heater and

striker for Dave Smith who worked on the Coffee

Diggers and Shovel Bits. At the start he was so

short that he had to stand on a box to strike at the

hot metal. After striking for the shoe turners,

Ted migrated to the Mould Steeling Department and

remained there until the late 1920s when he was

given employment of a lighter nature.

His brother Alf Bradley also worked for a while

at Chillington as a mould steeler. |

|

|

Mr. George Fisher started

at Chillington on 26th March, 1892 as a boy in the

Fitting Shop. He soon became a die sinker, but

unfortunately he lost the sight in his left eye

after it was struck by a chipping from a die. He

left the bench but returned during the First World

War. In 1927 he took charge of the Fire Station and

the upkeep of the fire appliances.

Strangely enough his son

Arthur also joined the staff at the Fire Station

after loosing the sight in his left eye. |

| Fred Gandy began in the

Warehouse Department under Arthur Parkes in June

1887. After 5 years he moved to the Horse Shoe

Department to strike for his brother Jack even

though this meant a drop in wages of 6 shillings a

week. After learning

his new trade he went on to punch the holes in the

horse shoes using the company's first punching

machine. It was driven by a steam engine and the

cogs jumped up and down to such an extent that it

could be heard all down Willenhall Road.

After 25 years he gave up

punching to go into cheeking up. His brother Jack

died in 1925 after 42 years service at Chillington.

His two other brothers also worked for the company. |

|

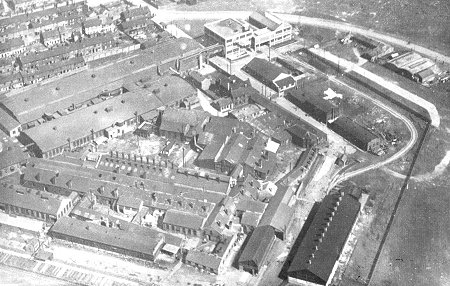

Chillington Tool Works from the air in

1928.

|

In the late 1920s the employees of the Mill and

Warehouse started a benevolent fund to provide financial help to

members who were away from work through no fault of their own,

for a period of 3 or 6 weeks. It also assisted in cases of

hardship.

Men and women over 18 years of age

contributed 3 pence and 2 pence each week

respectively, and younger members of staff

contributed one penny a week. When a man had been

away from work for 3 weeks he received £2 from the

fund, and a further £2 at the end of 6 weeks,

providing he was still off work and that sick notes

were produced. Women and juniors received two

thirds, and one third of the benefit respectively.

|

The Packing Warehouse in 1929.

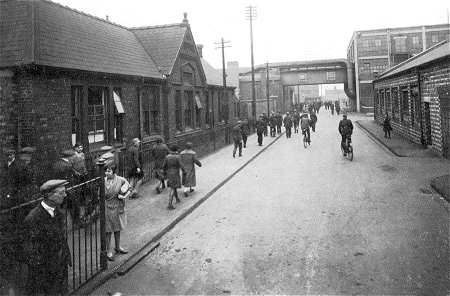

The main works drive in 1929.

Another view of the Packing Warehouse.

Some of the gas forging furnaces.

|

Packing

hoes.

|

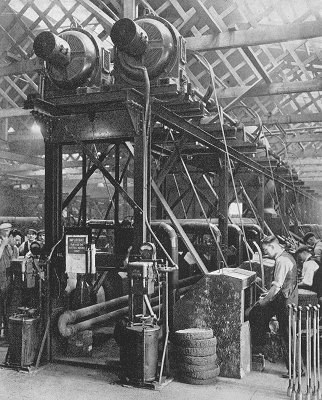

| A bank of

electrically-powered grinding machines.

Note the overhead line shafting.

|

|

|

|

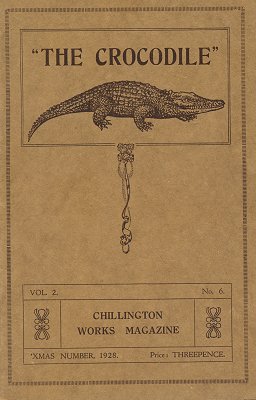

The company's works magazine. |

Building work in the late

1920s.

|

Another view of the new buildings erected

in the late 1920s.

|

In 1953 the company produced plantation hoes, bars

and forks; shovels, spades, axes and other edge

tools. Chillington and its associated companies

became the largest group of edge tool makers in the

world, exporting most of their products. The

associated companies, the EVA Industries Group of

Companies, were Edward Elwell Limited of

Wednesbury, A.W. Wills & Son Limited of

Wolverhampton, John Yates & Company Limited of

Wolverhampton, and the Pheonix Shovel Company

Limited of Cradley Heath.

By the 1950s a considerable jig and tool division,

equipped with modern high precision machine tools

had been formed to produce jigs, fixtures, and press

tools for the aircraft, motor and domestic appliance

industries. Jig boring and inspection were carried

out under ideal conditions in temperature controlled

rooms. The company also provided facilities for

special purpose machining, and manufactured rolls

and ancillary tools for tube production. |

An advert from the early

1950s. |

The works in the early 1950s.

|

The Chillington Tool Company has since moved to

Willenhall and the original site is now occupied by

an industrial park. The old Chillington canal basin

was purchased by the London and North Western

Railway in 1902 to become the Chillington

Interchange Basin. Sadly it is now in a derelict

state.

|

The old Chillington Interchange Basin as it

was a few years ago.

|

Return to the

previous page |

|