|

The

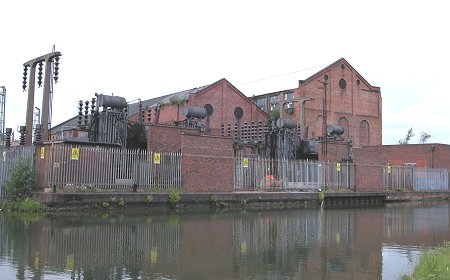

Commercial Road Power Station

The foundation stone of the Municipal

Lighting Works was laid on Monday, 21st May, 1894 at a ceremony

performed by the mayor, Alderman C. T. Mander. Several of the

guests were involved in the project. They included Thomas

Parker, the town’s consulting electrical engineer, who designed

and supplied some of the equipment, F. H. Lewis, the town’s

electrical engineer, A. P. Brevitt the architect, and H.

Willcock the builder.

Afterwards they were entertained at a

luncheon at the Victoria Hotel during which speeches were given.

Mr. Thomas Parker said that “eleven and a half years ago he came

to Wolverhampton a solitary working man, with one boy, and

started not many yards from where the foundation stone had been

laid that day. Since then they had built, under his supervision,

works for the lighting of a great number of towns and for a vast

number of purposes, and now Wolverhampton was waking up to the

uses of electricity, and he had been able to perceive the

consummation of a long-entertained hope in the laying of a

foundation stone which meant the lighting of Wolverhampton by

electricity. With all the systems devised, and with all the

various efforts made by others throughout the world, they had

that day adopted the system of his own devolution. They had, he

felt convinced, acted wisely in adopting that system, and it

would be the one that would be taken up elsewhere.”

The power station, built at a

cost of £32,000, officially opened on Thursday 30th

January, 1895. The opening ceremony was performed by

the famous 19th

century physicist and electricity expert Lord Kelvin, President

of the Royal Society.

The power station in 2004.

The coal fired power station depended upon

the canal for its supply of coal. When it first opened it

supplied an area of roughly 5 square miles using rope driven,

direct current generators which were shut down at night, when the

town was supplied from a 9,000 ampere hour battery.

|

A

visit by members of the Institution of

Mechanical Engineers in 1897 to

Wolverhampton Power Station in

Commercial Road

The erection and

equipment of these works was completed

in January 1895, when they were formally

opened by Lord Kelvin; and since that

date the supply of electricity has been

continuously maintained. The present

capital expenditure has been £38,000,

with a capacity of 15,000 lamps of 8

candle power. The buildings at present

consist of a main generating station and

three sub stations.

The system of

supply is the high pressure continuous

current. The current is generated at

2,000 volts pressure, and is distributed

by high pressure mains to the outlying

sub stations, where it is transformed by

means of motor transformers down to

about 110 volts, at which pressure it is

distributed to low pressure mains, and

thereby to consumers' premises.

The plant at the

generating station consists of four

complete generating sets, each

comprising a horizontal compound

condensing engine and a separately

excited continuous current dynamo with a

rope driven exciter. Three of the four

sets are of 140 kilowatt capacity, and

the fourth is of 65 kilowatts; all four

are rope driven, and each can develop

2,200 volts. The dynamos are two pole

inverted. The condensing plant consists

of a Ledward ejector condenser, and a

centrifugal pump driven direct by a

vertical steam engine for raising the

condensing water from a canal.

The boiler house

contains three Lancashire boilers, two

economisers, pumps, etc. and steam is

generated at 130 lbs. per square inch.

The chimney is 100 feet in height, and

is of circular section throughout

inside. A water softening apparatus is

in use, having a maximum duty of 300

gallons per hour. The high pressure

mains consist of vulcanized bitumen

cables laid in iron troughs, which are

filled with bitumen and closed with a

watertight iron lid. The low pressure

mains are armoured single conductor

cables buried in the ground.

The sub station at

the Town Hall performs a quadruple duty:

it serves as a central switching

station, takes its share of the

transforming, controls the arc lighting

circuits, and deals with a battery of

accumulators. It is equipped with three

motor transformers, each giving 400

amperes at 110 volts for the general

supply; one arc lighting transformer for

splitting the 2,000 volts into two of

1,000 volts on two separate circuits;

and one booster for supplying some 40

volts extra for the charging current for

the battery. The battery has a specified

capacity of 600 ampere hours. Mr. F.

Harman Lewis is the borough electrical

engineer. |

|

In 1892, Thomas Parker, whilst working for the E.C.C

developed what came to be known as “The Oxford System” for

electricity distribution, in which the central generating

station produced either 1,000 or 2,000 volts DC. This was in

turn converted to 200 volts D.C. by motor-generators that were

housed in sub-stations. The first installation at Oxford used a

2,000 volt high tension line. Following its success, similar

systems were installed at Birmingham, Charing Cross, Chelsea,

Sydenham and Shoreditch. This is the system that was used at

Wolverhampton.

The Commercial Road power station was

directly connected to the Town Hall, where the vault under the

sessions court contained a switching station, housing a rotary

converter, to convert the 2,000 volts DC supply from the power

station to 220 volts. From there it went to distribution

stations at the Art Gallery and the Free Library.

The initial equipment, which had a capacity

of 350KW, consisted of 3 DC generators, each powered by a steam

engine. The generators were provided by Thomas Parker Limited

and the E.C.C. At the time consumers paid 2½ pence per unit of

electricity.

|

The power station as seen from the canal.

|

The venture proved to be a success and by

1908 the capacity had been increased to around 6MW. The

following description from the 1908 Red Book includes a detailed

account of the equipment installed at the power station at the

time:

The buildings at present consist of a main

generating station and three sub-stations. The system of supply

is continuous current distributed on the 3-wire system at a

pressure of 440 volts between the outer mains and a standard

pressure of 220 volts for the supply to consumers' premises. The

outlying portions of the town are supplied by motor transformers, the driving current

of which is applied at a pressure of 2,000 volts from the

generating station, and is transformed down to the standard

pressure of 220 volts.

The plant at the

generating station

consists at present of eight complete generating sets, as

follows :-

One 200 B.H.P. Belliss two-crank high speed compound

condensing engine, direct coupled to a Parker two pole dynamo,

140 kilowatt, 2,000 volts. This generating set is used for

street lighting and for supplying current to the motor

transformers in the outlying parts of the borough.

Two 350 B.H.P. Belliss three-crank compound condensing engines, direct

coupled to Parker's dynamos, each 220 kilowatt, 550 volts.

One

460 B.H.P. Belliss three-crank triple expansion condensing

engine direct coupled to 300 kilowatt 550-volt E.C.C. generator.

Two 800 I.H.P. Willans three-crank compound condensing engines,

direct coupled to 500 kilowatt E.C.C. multipolar generators, 550

volts.

One Davey Paxman 800 I.H.P. three-crank compound

condensing engine, direct coupled to 500 kilowatt E.C.C.

multipolar generator, 550 volts.

One Bellis 800 B.H.P. 3-crank

triple expansion engine, direct coupled to 600 kilowatt 550-volt

Parker generator.

All these

generating sets are also

available either for electric lighting or tramway traction. The

five Belliss engines are arranged to exhaust into surface

condensers supplied by Joseph Evans and Sons, of Wolverhampton;

and the Meirlees Watson Company of Glasgow. The Willans engines

and the Davey Paxman engine each exhaust into a separate Ledward

ejector condenser, which is supplied with circulating water by

a Gwynne centrifugal pump, direct driven by a 20hp. Parker

motor.

The combined lighting and traction

switchboard was supplied by Thomas Parker, Limited, to the

design of the chief engineer.

The Boiler house contains six Lancashire

boilers, 30ft. by 8ft., and two "Economic" boilers, 14ft. 6in.

by 9ft. 9in., two economisers, and the necessary feed Pumps,

etc., and a water softening plant is in use. These boilers work at a pressure of 130lbs. per square

inch and have

a maximum duty of 2,000 gallons per hour.

The brick chimney is 115 feet in height,

and is of circular section throughout inside, and an induced

draught exhaust fan has been installed to improve the draught of

the chimney.

A large Battery Room has been built over

the present boiler house for the purpose of containing two

storage batteries, one of 260 Tudor cells for lighting purposes,

and one of 263 cells for tramway work.

An Auxiliary Station has been opened at the

Refuse Destructor, in Crown street, and the following plant

installed:

Two 125 Kilowatt multipolar shunt wound Parker

generators, coupled direct to two Belliss two-crank compound

enclosed 180 B.H.P. steam engines. The steam for driving these

engines is supplied from the refuse destructor.

A new generating station is now in the

course of construction at Commercial Road, especially designed

for the purpose of power supply for large consumers. The initial

equipment of this new station consists of two steam turbine

generating sets of 1,000 kilowatts capacity each. The turbines

being constructed by Williams and Robinson, of Rugby, and the

generators by the Electric Construction Company, Wolverhampton.

Current will be supplied from these generating sets at a

pressure of 6,000 volts alternating.

The boiler house equipment of the new

station will consist of two large water tube boilers, by Babcock

and Wilcox, of London, each boiler having an evaporative

capacity of 20,000lbs. of water per hour. The waste gases from

the boilers after passing through Green's economiser are

discharged into a Steel Chimney 175 feet in height, supplied and

erected by J. Thompson.

The extensions to the boiler house and

engine room were officially opened on 16th March,

1908 and increased the capacity to 6.4MW. The new buildings were

constructed by local builder H. Gough.

|

The old generating hall seen from the

canal.

|

Under the Corporation Electric Lighting

Extension Order of 1913, the area covered by the power station

was doubled to 11 square miles by the inclusion of the Parish of

Bushbury.

In 1925 the DC generators were scrapped and

replaced by two 7,500KW turbo alternator sets to increase the

station’s capacity to 23MW. There were then 7 turbine-driven

alternators provided by Siemens Brothers Limited, of Stafford;

the British Thomson-Houston Company Limited, of Rugby; and the

Electric Construction Company, Limited, of Wolverhampton.

The boiler plant consisted of large and

modern Stirling, and Babcock and Wilcox Water-tube boilers, with

economisers and water softeners. The power station then fed an

area of 47 square miles, including Brewood and Codsall. The

Borough's own Acts of Parliament in 1928 and 1932 extended the

area to 106 square miles to include Saredon, Brineton, Blymhill and Penkridge

to the north, Pattingham to the West, and Albrighton

and Tong to the north west. |

|

The derelict site as it is

today. |

In 1925 the power station came under the

control of the West Midlands Joint Electricity authority that

took over the existing electricity supply companies and

generating stations in Staffordshire, Shropshire and

Worcestershire. In 1933 the three phase AC distribution system

was introduced, and in 1936 a new generating hall was added. At

the time about 80% of the supply was taken by industry. |

|

The power station

switchboard room in the early 1930s. |

|

An advert from the

early 1930s. 83 Darlington Street was the

location of the department's showroom. |

|

Another advert

from the early 1930s. |

| In 1948 the industry was nationalised, and

local supplies were proved by the Midlands Electricity Board (MEB)

as from 1st April. The power station continued

much as before, but by the 1970s at 80 years of

age it was getting a little old fashioned and

un-economical when compared with the large

efficient power stations of the day. |

A final view of the

surviving generating hall. |

| As a result it closed in

the late 1970s, and a local landmark, the cooling tower, was

demolished. The power station was the only single-tower power

station in the midlands. The power station’s fleet of twenty

canal boats were in use until the middle 1950s, after which the

coal came-in by road. |

|

Return to the Canals

and Industry Menu |

|