| The

moulding and casting process

Sadly very few working foundries

still survive in the UK and the once familiar moulding

and casting skills are rapidly disappearing. The

manufacturing processes and terminology were well known,

but are now alien to many people. The following section

describes the processes that go into producing a casting

from beginning to end. |

|

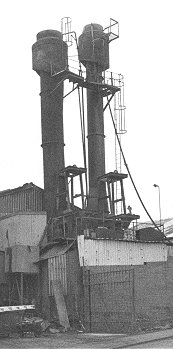

An early type of cupola. |

The molten iron is usually

produced in a cupola furnace. This is a vertical

cylindrical steel shell with a “well” at the bottom to

collect the molten metal.

The inside can be made of fire

bricks, but is normally constructed of steel, with a

water jacket for cooling and lined with clay. The well

at the bottom is lined with sand and the furnace is

charged through a door at the top with pig iron or scrap

iron, coke and limestone. |

|

Air is necessary

for combustion and this is blown into the furnace

through several tuyeres (blast holes) near the base.

There are cold blast cupolas where the air enters at

atmospheric pressure and hot blast cupolas where the air

is preheated by the heat from the exhaust gases. This

type of cupola has an increased melting rate, produces

hotter metal, and uses less coke.

The coke burns

fiercely thanks to the air blast and the metal soon

melts. The limestone acts as a flux, reacting with the

sand and ash etc. to form slag, which floats on top of

the molten metal. This is removed through a slag hole

below the tuyeres.

The cupola

extends above the charging door to produce a chimney

where the exhaust gases are removed and cleaned before

entering the atmosphere. The coke can be fired directly

to start the combustion process, but electricity, oil or

gas are often used with carbon being added to the

charge. |

A more modern cupola. |

Cupolas at Hermit Industries in

Upper Gornal. |

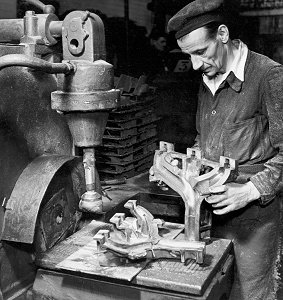

Iron is usually

cast in sand into which an impression of the item to be

cast is made. The impression is made by a pattern, which

is produced from the original drawing and is slightly

larger than the final casting. Patterns were originally

produced in wood, with several special types being used

including jelutong from the Philippines, cherry wood,

mahogany, maple, and white pine. Pattern making is an

extremely skilful occupation; the patterns must be

precisely shaped and accurately finished.

As the molten

metal cools it shrinks, and to allow for this the

pattern must be larger than the finished product.

Pattern maker’s rules are used, which are scaled to

allow for shrinkage in various metals. Although

traditionally made of wood, many patterns today are made

in resin that is shaped on a milling machine. The

machines can be computer controlled and work directly

from the original drawing data. In the past, every

foundry had at least one pattern maker but today many

buy their patterns from specialist companies. |

| If the casting is hollow, a core

is inserted in the mould to shape the interior. Cores

are made from silica sand (with a low clay content) and

held together with a bonding agent such as sodium

silicate, which can be bonded by passing carbon dioxide

through the mixture. Such a mixture is very strong and

has good dimensional stability. Cores were originally

made in a core box but today they are usually formed by

machine. The mould is made

in two halves, one forming the bottom and the other the

top. Each half consists of a box into which sand is

tightly packed around the pattern. When the pattern is

removed its impression is left in the sand and this

forms the mould. |

A core box and filling machine. |

|

Different types

of fine sand are used with chemical additives that bind

the sand together to give an accurate and detailed

impression of the pattern. The sand is recycled and soon

blackens from its contact with the molten iron.

|

|

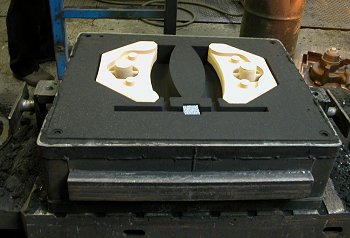

The bottom half of a moulding box

with 2 cores in place. |

When the two halves of the mould have

been prepared and any cores inserted they are fastened

together in preparation for casting.

The mould will include a network of

small flow channels that lead the metal into all of the

corners of the impression in the sand.

Provision is also made for the

escape of the hot gasses that are released when the

molten metal enters the mould. |

|

When the casting

has solidified and cooled it is knocked out of the mould

and taken to be dressed (cleaned up). Metal will have

solidified in the flow channels and this will be

attached to the casting and must be removed. Any

extraneous pieces are cut off and ground flat using

grinding wheels. Shot blasting can also be used to give

a clean finish. Precision castings are often accurately

machined and may be tested for unwanted cracks or flaws.

Crane Foundry

products are made of grey cast iron, in which silicon

causes the carbon to come out of the molten solution as

graphite, to leave a matrix of pure soft iron. This type

of iron produces sharp castings and has a high

resistance to corrosion and wear. It also has a good

thermal conductivity and so is ideal for saucepans and

casseroles etc. and is easy to machine. |

|

Return to

the

previous page |

|