| In the late 19th century, bicycle manufacturing

became an important industry in Wolverhampton, employing

many people. By the early years of the 20th century, the

number of manufacturers had fallen, but many of the

smaller businesses had been replaced by sizeable

factories, where large numbers of people assembled

cycles. The larger manufacturers such as Sunbeam, Star,

and Wearwell, produced a considerable number of

machines, most of which were lined, often in gold.

Lining was an extremely skilled occupation, usually

carried-out by a team of girls and women, mainly because

of the high level of dexterity required to achieve the

required results. Any labour-saving aid, that would

simplify, speed-up, and cheapen the process would be

warmly welcomed.

The Wearwell Cycle Company Limited had a large

factory in Pountney Street, producing all kinds of

cycles. Sometime after 1900 Mr. J. H. Pickard began to

develop a lining pen at the factory, to simplify and

cheapen the lining process. His initial apparatus used a

complicated and expensive set of guides, but appears to

have been successful.

The following details from 1910 give an impression of

the savings that were achieved at the Wearwell factory,

when using the Pickard lining apparatus.. |

| The initial development work at the factory ended in

1911 when Wearwell went into liquidation. William

Clarke, who had been running the company, purchased the

ailing Wulfruna Cycle Company based at Eagle works in

Great Brickkiln Street, and formed the Wulfruna

Engineering Company, to produce Wearwell and Wolf

cycles. |

| By this time Mr. Pickard had developed his patented

lining pen, a simple and cheap device that could be used

to line cycle frames, forks, and mudguards, at a quarter

of the cost of traditional brush lining. The old

method often took years to learn, whereas the lining pen

could be mastered in a few minutes.

The advantages of using the the lining pen, and its

potential market, must have been well understood by the

Wulfruna Engineering Company, because by 1912 it was manufacturing, and selling the product. |

Pickard's Patent Lining Apparatus. |

| The device is a type of syringe, consisting of a

metal tube, with a small diameter nozzle at one end,

through which the paint flows. At the other end is a

metal piston, and operating lever, to force the paint

through the nozzle. An adjustable guide is attached to

the side of the pen, to enable a line to be drawn

parallel to the side of an article. The lining pen is

held in the hand, in the same way as a writing pen.

|

| The paint supplied with the pen dries within a few

minutes, and can be coated with the layer of protective

varnish, applied with a camel hair brush. Both the

varnish, and a suitable brush are included in the box,

with the apparatus. |

|

Lining a gent's cycle frame. |

To line the top and bottom tubes of a gent's cycle

frame, the frame is held in the left hand, and rested on

the bench. The pen is held lightly, but firmly in the

right hand. To line the back and chain stays the frame

is simply reversed.

To line the seat tube, rest the frame on the back

fork ends. |

| A lady's cycle frame is lined in the same manner,

except that the frame is held slightly sideways to line

the loop tube. |

Lining a lady's cycle frame. |

|

Lining front forks. |

To line the front forks, the steering column is rested on the bench, and one

side of the lines on each fork are completed. The

forks are then reversed with the ends of the forks

pressing on the bench. The opposite lines are then

drawn. |

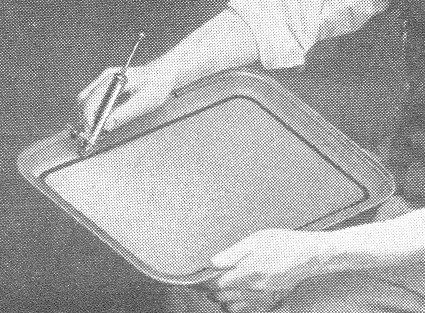

| To line a mudguard, place both ends on the bench as

illustrated, draw the line on one side, then reverse the

mudguard to draw the line on the other side. If a

central line is required, simply adjust the guide on the

pen, and draw the line where necessary. |

Lining mudguards. |

|

Lining a gear case. |

To line a gear case, hold it firmly in the left hand

and carefully draw the pen around the outside edge.

The guide will of course accurately follow the edge.

|

| To change colour, pour a small amount of turpentine

into a container, fill the nozzle, and press your

thumb on the end to squirt the liquid through the

nozzle, so removing any residual paint. The tube can

then be washed-out with turpentine.

When a large quantity of work is to be carried out,

it is worthwhile to have individual pens for each

colour, to reduce cleaning time. |

|

A price list from 1912.

The product was in use at Sunbeam, as can be

seen from this testimonial.

|

An article from May, 1914. |

The lining pens would be a useful tool for anyone

repairing, or restoring a cycle, and also in

cycle shops, where cycles were often assembled to

individual customer's requirements. |

An advert from 1917.

Another advert from 1917.

| Manufacturing would have ceased in 1922 when the

Wulfruna Engineering Company closed, after the death of

its owner, William Clarke. Undeterred, Mr. Pickard

continued to develop his apparatus, and launched an

improved version, which was sold under the name Pickard

& Smith, based at 20 Paget Road. The improved pen

had a freely rotating hardened steel wheel, mounted in

front of the nozzle, to evenly spread the paint over the

surface. The special paint supplied for the apparatus,

contained varnish, so that is was no longer necessary to

apply a protective coat of varnish. |

The improved lining apparatus.

|

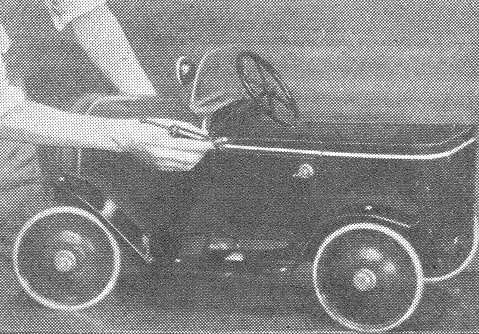

The booklet that came with the

improved apparatus suggested a variety of applications

such as lining children's toys, or prams, or even lining

a tray. |

|

Lining a tray.

|

|

A later price list.

|

Return to

the

previous page |

|