|

6. The works under Stewarts and Lloyds,

1920 - 1966

| We can interrupt our source here to say

something further about this important change in ownership.

Stewarts and Lloyds were a very old company, an amalgamation of a

company set up by Samuel and Edward R. Lloyd in Birmingham in 1859;

and a company set up by Andrew Stewart in Glasgow in 1861. By 1920

it had wide interests in iron and steel but mainly concentrated on

tube making. In the early 20th century the company

adopted a policy of securing its position by acquiring companies

which would enable them to control all of their supplies,

manufacture and distribution.

So Alfred Hickman Ltd was a very

suitable acquisition, and with it they got the Hickman owned company

Ernest N. Wright Ltd. of Monmore Green and Millfields.

By the time of the takeover in 1920 Wrights were mainly

constructing furnaces for the production of iron and

steel and this they continued to do, over an even wide

range of furnaces, after the takeover. |

A long service certificate. |

|

Fettling an open hearth at Bilston. |

(What Stewarts and Lloyds did not acquire was

Hickman's Tarmac business which was an independent

company. It is not clear but they probably did

not get the basic slag fertilizer business either). |

To return to our anonymous source:

"A Morgan Skelp Mill was installed in 1921

for the production of strip for tube making. A little later the

26‑inch billet and bar mill was modernised to a 28‑inch mill,

electrically driven and capable of producing slabs in addition to

the billets and bars required for tube making. A feature of this

mill was the very good shape of rounds produced which, coupled with

the steelmaking techniques employed, enabled bars to be used for

tube making in the black‑conditions. This was the only works that

was able to do this on a regular production basis. Whilst this was

rightly a matter of great pride to the mill teams, it was, of

course, expensive in terms of manpower, but nevertheless justified

itself for many years.

| "Instrumentation on the Open Hearth Furnace

was applied initially in the late 1930s, roof temperatures and

chequer temperatures being the first points tackled. With increasing

experimentation and sophistication coupled with experience shared

with one or two other works, “the clocks” as the furnace men called

them, became not only accepted but indispensable. |

An early 20th century view of

the works. |

|

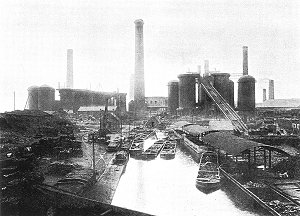

A view of the works probably

in the first half of the 20th century.

The canal

remained an important feature of the works which also

had an internal railway system. |

"From the employees’ point of view,

reference must be made among other things, to the provision of a

licensed canteen, along with slipper baths and a swimming bath in

1910. These were the outward and visible signs of concern for the

employees welfare that had existed for many years and included a

provident fund and other methods suitable to the age which, the more

enlightened employers adopted in those days.

| Disputes and strikes

did occur, of course, but provision was made for the wives and

children of employees on strike to have a plate of soup if they

cared to come for it. Many of them did!

Between the wars under the

new ownership, this spirit of interdependence was fostered and

culminated in 1939 in the opening of the Social Centre, built by the

Company towards the furnishings of which the men made a substantial

contribution out of their own funds." |

Another early 20th century

view of the works. |

|

|

|

|

|

Return to

1900-1919 |

|

Return to

the

beginning |

|

Proceed to

World War 2 |

|