|

The Fast

20-Seater; What Guys are Doing

An article from 'The

Commercial Motor', 30th October 1928. Courtesy of Brendan Kinsella. |

|

The New OND

Model Guy is a Robust Product at a Moderate Price

Much attention has been given during recent

years to the development of the large capacity coach and bus

capable of travelling at much higher average speeds than were

formerly possible, and it seems that the smaller passenger

vehicles have been somewhat neglected. For this reason the

latest product from the Wolverhampton works of Guy Motors,

Limited, should, receive a warm welcome from those users and

potential users of vehicles of moderate capacity.

Even a cursory inspection of the new OND

model Guy chassis will reveal the fact that it is no ordinary

semi - converted goods model, but one designed expressly for the

purpose which it is called upon to serve, including as it does,

an extremely powerful and live engine, a frame dropped at the

dash and arched over the rear axle, Dewandre-operated

front-wheel brakes, and a most complete equipment. |

|

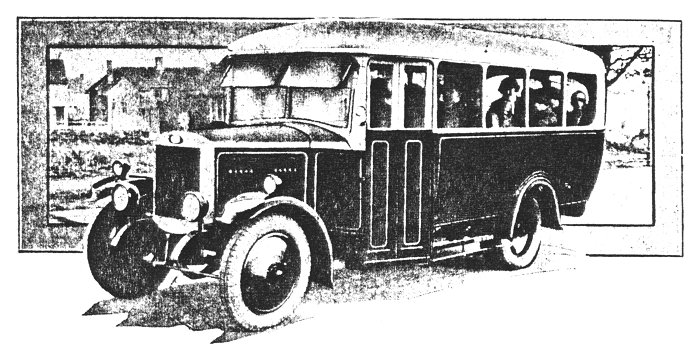

A 20-seater bus in which the new Guy

chassis is used. |

|

Road tests, with this model, fully laden;

have revealed a surprising turn of speed. The vehicle speed at

1,000 rpm. of the engine is 18.8 mph. and the engine is easily

capable of 8,000 rpm.; actually 49 mph. has been obtained with

ease. Gear changing is finger-light, the steering easy and

affording an excellent lock; furthermore, long, fairly stiff

gradients can be climbed on top gear and on the lower speeds

little more than a faint hum can be heard.

The following are the main dimensions,

etc.: Engine four cylinders, 90 mm. bore and 130 mm. stroke,

rated at 20 hp.; gear ratios, top, direct, third, 1.7 to 1,

second, 2.61 to 1, first, 5.27 to 1, reverse 8.23 to 1; axle

ratio, 5.4 to 1; wheelbase, 12 ft. 3 ins: track, 4 ft. 9½ ins.;

overall length, 18 ft. 10 ins.; dash to end of frame, 14 ft. 8

ins:; frame height under load 2 ft.; ground clearance under

front axle, 12½ ins. under rear axle, 7¾ ins.; turning circle,

approximately 50 ft.; chassis weight approximately 35 cwt.

The frame is built up with side members 6

ins. deep with 2¼ ins. flanges, the material being ¼ ins. thick.

There is a deep, dropped cross-member at the front to carry the

forward pinion support of the engine-gearbox unit, and both

tubular and channel-section cross members elsewhere, two being

bolted right through to the pressed-steel rear spring brackets.

The suspension is by long semi-elliptic springs with bushed

eyes. Tecalemit-Zerk lubricating nipples are

utilized throughout the chassis. |

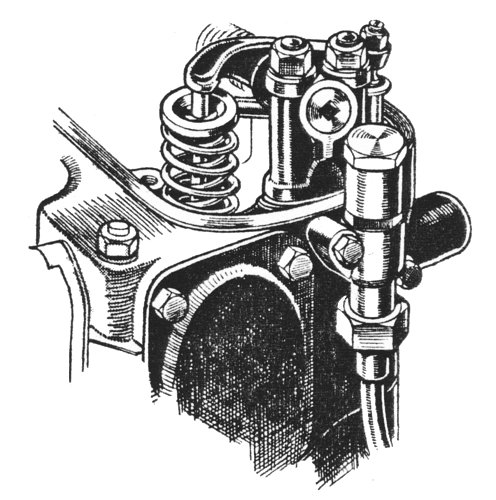

The forward end of the engine in the new

Guy, showing one of the rocker-operated valves, and the camshaft

oil lead containing the relief valve. |

In the power unit the four cylinders are

cast en bloc with the upper half of the crankcase and the head

carries the valves and rocker gear, which is operated by

push-rods from the camshaft in the crankcase.

The rockers carry

ball-ended adjustable pins working in oil cushioned cups on the

push rods.

Cast iron pistons, each with three ordinary

and one scraper ring, are utilised.

The gudgeon pins are dowelled into the

pistons and held by wide spring steel bands. White metal-lined

shells are fitted into duralumin connecting rods. |

| There are three main bearings for the extremely robust

crankshaft. Quietness is assisted by the use of helical timing

gears and a skew-gear for the cross-shaft, which drives a Lucas

magneto at the near side and a centrifugal-type water pump at

the other. There is a breather on the timing case and the dynamo can be

flange-fitted at either side. Circulation of the engine oil is effected

by a submerged pinion-type pump driven from the camshaft. The

oil enters a readily accessible external filler chamber from

which one lead takes it to the main bearings and thence through

the drilled crankshaft to the big ends, whilst a second lead

takes it to a relief valve chamber bolted to the cylinder head,

and from this to the hollow shaft carrying the rocker arms.

Distribution of the mixture from the triple-diffuser Zenith

carburettor is effected within the cylinders, but the exhaust

manifold is external. A hot-spot is embodied in the arrangement. |

|

The cooling water is circulated around a

gilled-tube, cast-aluminium radiator of pleasing design through

which air is drawn by a large cast-aluminium fan mounted on

ball-bell rings on an eccentric spindle and driven by an endless

rubberised-fabric belt. The bhp. developed is 23 at 1,000 rpm.,

34 at 1,500 rpm., and 38 at 2,000 rpm.

Twelve compression springs are utilised for

the single-plate clutch of the semi-steel flywheel, which is

totally enclosed in the engine-gearbox unit but can be examined

through an inspection hole provided with a steel cover.

|

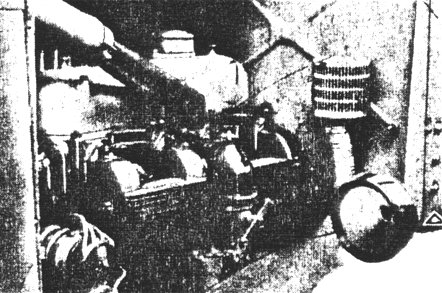

Engine accessibility as exemplified in the

Guy. Note air cleaner. |

|

Four forward speeds are given by the

gearbox, which has short, stiff shafts and wide-toothed pinions

carried in a one-piece casting, in the cover of which is mounted

the selector mechanism. A particularly interesting feature is

that either central change or right-hand gear control can be

provided. In the latter case, the lever is mounted on a cast

aluminium extension of the gearbox cover. At the off-side of the

gearbox is a plate which can be detached to permit a power

take-off from the layshaft, whilst at the rear of the box on the

third motion shaft is the positive gear drive for the

speedometer.

|

|

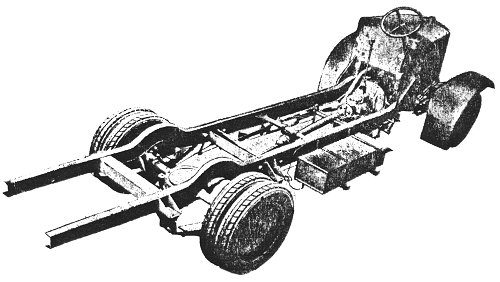

A semi-plan view of the new OND Guy

passenger chassis. |

Behind the gearbox is a two-piece tubular

propeller shaft with three ply Hardy flexible fabric joints at

the forward end and a Spicer all-metal joint with a plunger at

the rear end, a centre bearing being provided.

A horizontal banjo forged casing of

exceptional strength is used for the rear axle, which is driven

by an underneath worm. All the wheels are carried on

taper-roller bearings.

|

|

The front axle is of the reversed Elliott

pattern with the truck rod at the front. This rod has ball and

socket joints, whilst the drag-link is provided with spring

loaded ball joints.

Duplex brake shoes are provided for the

rear wheel drums, one set of shoes being controlled by the hand

lever, whilst the other set is coupled up with the front brakes

and operated through the Dewandre servo. Spherical bushes on the

two cross-shafts prevent any risk of binding through frame

flexion. The brake drums are deep-flanged forgings with, dust

covers for the shoes and the hand brake is not compensated, so

simplifying the gear.

|

|

Brake adjustments are made by turnbuckles

and sprung snap-over wing-nuts at the extreme ends. At the near

side of the frame is mounted a 16-gallon petrol tank from which

the carburettor is supplied by an Autovac.

It is obvious that close attention has been

given to that vitally important point, accessibility. Inspection

covers are provided for the timing gear, Bendix pinion of the

starter, big-ends, etc., whilst the three-point mounted

engine-gearbox unit can easily be removed from the front.

Although the chassis we illustrate is

arranged for the normal driving position the company is quite

prepared to provide a chassis with forward control, and to

facilitate this, the engine is so designed that all its

auxiliaries are accessible from the near side, although the

dynamo can be mounted at the other side if desired.

The tyres provided as standard are 30 inch

by 5 inch twins at the rear, all on steel-disc wheels, a spare

wheel and tyre being included. As an alternative, 33 inch by 5

inch tyres can be provided at an extra cost.

|

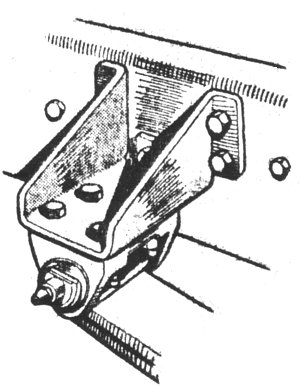

The rear spring brackets are light but

strong. |

|

The chassis is designed to carry a net load

of 27 cwt., and the gross load, inclusive of body, must not

exceed 2 tons 5 cwt. With 12 volt, five lamp lighting set,

starter, speedometer, air cleaner, electric horn and Dewandre

servo, the chassis price is £445.

|

|

Return to the

previous page |

|