|

At the beginning of the war, Guy’s chief

engineer went to Mersa Matruh in North Africa to see the Guy

armoured vehicles in operation in the North Africa Campaign. The

vehicles performed well and gave good service.

Many Guy military vehicles travelled to

Dover, at the beginning of the war. They were taken to France

for use by the British troops. When the country was invaded by

the Germans, and the allied troops were evacuated in May 1940,

the vehicles, like many others, were driven over the cliffs to prevent

them falling into the hands of the enemy.

Shortly after the start of the war,

production of the ‘Ant’ and ‘Quad Ant’ range moved to Karrier.

Guy did however, produce some armoured bodies. 21 Guy ‘Lizard’

armoured command vehicles were produced in the factory, as were

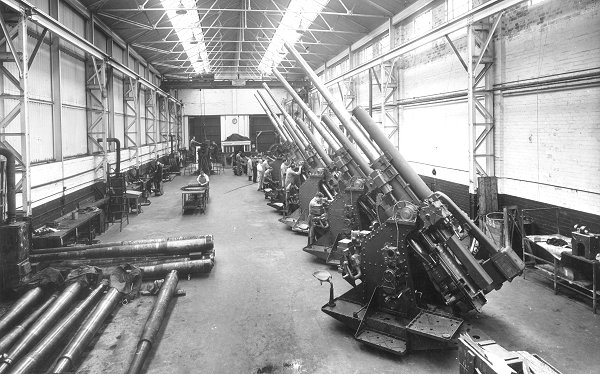

several 4x4 universal gun carriers. The factory also produced

anti-aircraft, and other guns thanks to the company’s reputation

for high quality, precision work.

Part of the gun shop.

Production of searchlight generator

vehicles soon ended due to the development of radar. Some

civilian vehicle production did take place at Park Lane due to a

shortage of vans and lorries for essential services and

supplies. Each vehicle required a government permit in order for

it to be built. |

A 1937 'Arab' in operation during the war at Wombourne.

| Around the same time as production of searchlight generators

ended, Guy received an order from the Ministry of Supply for the production of a chassis suitable

for a use with a double-deck bus body. At the time there was a

severe shortage of buses, many of which had been lost in the

blitz. The specification had been completed on 5th September,

1941, and the prototype was ready on 31st March, 1942. The new vehicle, called the ‘Arab’ utility

double deck bus was based on the original ‘Arab’ bus chassis

from 1933. Due to the shortage of materials, the aluminium parts

were made of cast iron, which increased the chassis weight by

20%. Great attention was paid to increasing the life of

components, and the time between vehicle overhauls. The new bus

gained favour with many operators because of its reliability and

low running costs. The buses were supplied with 5-cylinder Gardner '5LW'

engines, other than a few that were built to operate in hilly

areas, which had the larger Gardner '6LW'.

Sydney

Guy's son Robin joined Guy Motors in the autumn of 1941 after

leaving school. He started in the drawing office, and worked on

the 'Arab' utility bus. He joined the navy, then trained at

Gardner Engines in Manchester. |

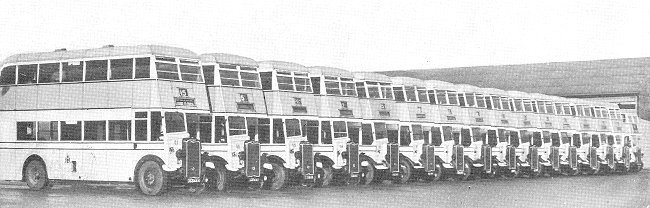

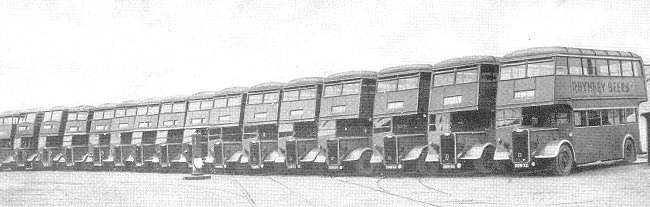

A fleet of 'Arab' utility buses.

A Guy 'Arab'. Courtesy of Brian Shaw.

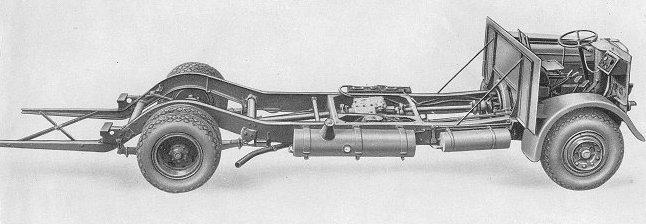

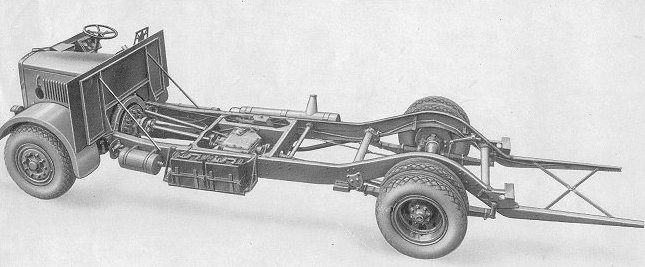

A Guy 'Arab' chassis. Courtesy of Brian Shaw.

Shaw.

Another view of the Guy 'Arab' chassis. Courtesy of

Brian Shaw.

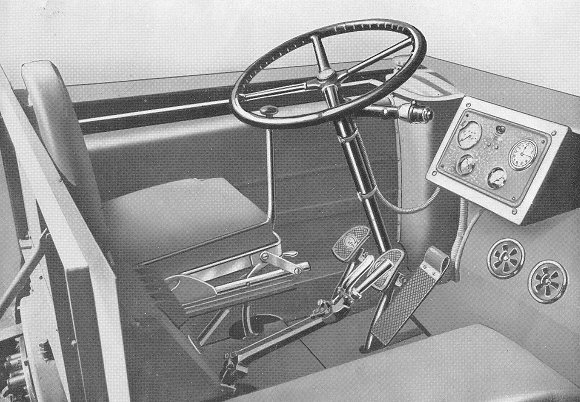

The 'Arab' driving compartment. Courtesy of Brian

Shaw.

Courtesy of Brian Shaw.

A Guy 'Arab'. Courtesy of Brian Shaw.

Guy 'Arabs' operated by the Lancashire United

Transport & Power Company. Courtesy of Brian Shaw.

A fleet of Guy 'Arabs' operated by Glasgow Corporation

Transport. Courtesy of Brian Shaw.

A fleet of Guy 'Arabs' operated by Newport Corporation

Transport. Courtesy of Brian Shaw.

Courtesy of Brian Shaw.

Guy 'Arabs' operated by the Maidstone Corporation

Transport Department. Courtesy of Brian Shaw.

| Initially Guy was the only wartime manufacturer of double

deck bus chassis, until December 1942 when Daimler received an

order from the ministry for some 'CWG5' chassis. Daimler's

factory in Coventry had been badly damaged during the air raids,

and so production began at a factory commissioned for the

purpose by the Ministry of Supply. This turned out to be part of Courtaulds' factory in

Wolverhampton. So for a time, all UK double deck bus chassis

were built in Wolverhampton.

Over 2,700 Guy bus chassis were built during the war. The

orders not only kept Guy going at the time, but also

established the company as one of the leading suppliers of bus

chassis, which led to the continuation of orders for many years

to come. During the war the factory worked long hours to keep up with

the demand for vehicles and components. Employees worked from 8

a.m. until 8 p.m. on weekdays, 8 a.m. until 4.30 p.m. on

Saturdays, and 8 a.m. until 12.30 p.m. on Sundays.

There was a severe shortage of labour, which was solved by

the company in a manner that made history, and changed the law.

At the time, part-time workers were not eligible for national

insurance, and so would not look for work through the labour

exchange. |

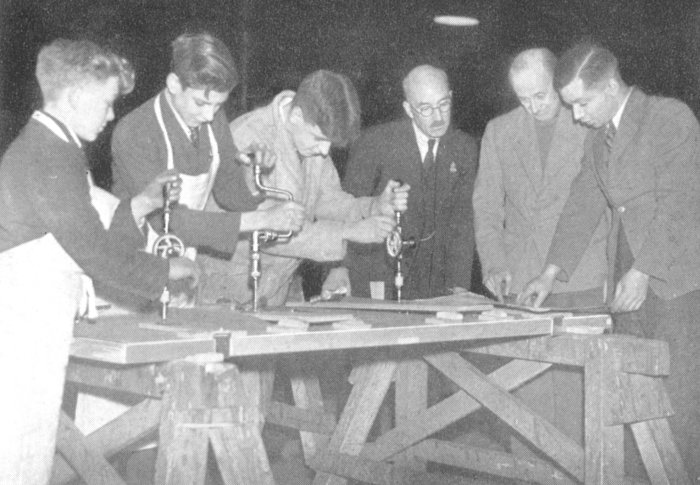

The late Judge Caporn and schoolboy

volunteers at work in the body shop.

|

As a result Sydney Guy instigated a scheme

which resulted in him being threatened with imprisonment and fines.

Fortunately the Ministry of Employment quickly realised that such a

scheme was a necessity, and so similar schemes were set up

throughout the country.

Guy gave senior pupils and teachers from

local schools, the opportunity of doing voluntary war work

during their holidays. They were employed on the assembly jigs

for the bodies of army trucks.

Over 1,000 people answered the initial

advertisement. The response was so great that a separate

department was set up to organise the scheme.

When the pupils and teachers were at

school, part-time women workers took their place during the day,

with business and professional men, doing a night shift.

One of the first, and most enthusiastic

volunteers was Judge Caporn, a County Court Judge. |

|

| Guy Motors participated in the National Savings Scheme, and

Sydney Guy gave six pence on each certificate purchased. The

company also produced its own I.D. card with photo and finger

prints on the back. |

|

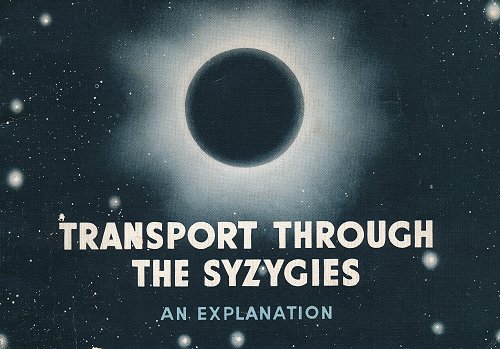

A booklet produced as an advert, and an

explanation of the 'Syzygies' name. |

During the war the scope of advertising was greatly

restricted, and so Guy started a clever campaign in order to

keep the company’s name alive. The campaign was influenced by

the widespread interest in crosswords, and the ‘Brains Trust’ on

the radio, which provided relief from the problems of war.

It consisted of a series of clever adverts entitled

‘Transport through the Syzygies’ which gained a lot of interest.

People at first thought ‘syzygies’ was a spelling mistake, until

it appeared time, after time. |

|

Guy received many letters from people

expressing their ideas about the word, which was in fact used in

its astronomical sense, meaning a computation of time. |

| The following is an article from the Express & Star,

Wednesday 3rd January, 1945: |

|

This is Their

War Effort – VI

Wolverhampton Firm Pioneers in

Welding Armour Plate and Use of Part-Time

Workers

With the production of many

thousands of military vehicles of several

successful types, and over 2,000 war-time bus

chassis to their credit, Guy Motors Limited,

Wolverhampton, have, in the opinion of their

chairman and managing director, Mr. Sydney S.

Guy made two important contributions to the

nation’s war effort, in addition to their main

production activity.

The first was concerned

with the welding of bullet-proof armour plate

for armoured cars and tanks; the other with the

introduction of part-time workers into industry.

For over 20 years the

company has paid much attention to vehicles for

military purposes and has produced many types.

When expenditure on the army reached very low

levels, and military were ordered in such small

quantities that they could not be produced

profitably, Guy Motors designed and developed

military types largely at their own expense, and

during the 14 years up to 1937 produced 14

different types.

Supply

Maintained

Very shortly after the war

started, Guy vehicles or proved quality were

available for military duty in large numbers,

and the supply has been steadily maintained ever

since.

One of the most successful

types has been the Quad Ant, a four-wheel drive

vehicle developed from an earlier model. It has

been adapted for a number of uses, notably as an

artillery tractor. It was on a variety of this

type, with the engine at the rear, that the

first British armoured car body of all welded,

bullet-proof, armour-plated construction was

mounted.

Convincing others that

welding was better than riveting for this

purpose was not easy, but now the system is

widely applied, not only to armoured car bodies,

but also to tanks. As early as 1940 details of

the method were sent to America, and though

there may be no connection, it was reported not

long after that the first American tanks with

welded hulls were coming off the line. Guy

Motors have produced a considerable number of

armoured cars of their own design, and have

recently been producing hulls for the Humber

armoured car.

Mr. Guy is equally proud of

the part the firm played introducing the

extensive use of part-time labour into war

factories. It was found that many professional

and business men were not only able, but anxious

to devote their evenings to factory work, and

that many women were prepared to work part-time

during the day. Special arrangement of working

hours was made for them, and in a very short

time the firm had more applicants than they

could place.

It seemed, however, that

the law did not provide for the employment of

part-time workers, and the Ministry of Labour

pointed out that Mr. Guy was in danger of very

severe penalties, both fines and imprisonment. A

stand was made, but at one time it seemed that

the part-time work would have to be abandoned.

The law was changed soon afterwards and

subsequently part-time work for some categories

became compulsory.

The achievement of

part-time workers in the factory has been

considerable, and many of the women who started

in this way have switched over to full-time

employment. They, and other women have proved

outstandingly successful at a wide variety of

jobs in the factory.

Buses for

War Workers

In 1942 It was found that

buses would have to be produced to enable

transport organisations to cope with the huge

task of carrying workers to their work, and as

sufficient military lorries of a type Guy Motors

were producing had been made, they were switched

over to making bus chassis.

Although of Guy design, the

wartime chassis had to conform to Ministry of

War Transport specifications and the materials

used were not always exactly what the company

would have wished, resulting in the chassis

being heavier than its pre-war equivalent. Over

2,000 war-time chassis have been produced in

about two and a half years.

In addition to their

production effort, Guy Motors have reconditioned

large numbers of engines and have continued to

supply spare parts which kept vehicles in

service. The stores department has recently

supplied from stock, spares for vehicles 22 years

old. |

|

|

|

|

|

|

Return to

Into the 1930s |

|

Return

to the

beginning |

|

Proceed to

The Post War Years |

|