Arthur G. Booth had a distinguished career as a design engineer. His

career began at Wolverhampton, working for the Clyno Engineering

Company, and later A.J.S. After A.J.S. went into voluntary liquidation

he moved to Singer Motors Limited and later Humber Limited. He ended up

as Chief Consulting Engineer to the Rootes Group and was Chairman of the

Automobile Division of the Institute of Mechanical Engineers. The

following section is taken from his Chairman's address, which was

delivered at a meeting of the Automobile Division at the Institute on

9th October 1956. As the complete address is quite long, we have only

included the sections that are about his time in Wolverhampton, to

reduce the time taken to download.

His daughter, Mrs Eileen J. Stephens has kindly given us a copy of

the paper and some of her father's photographs and we would like to

thank her for allowing us to include them here.

An extract from the

address of the Chairman of the Automobile Division

Experiences During

Forty Years of Automobile Design

By A. G. Booth,

M.B.E. (Member of Council)

|

Arthur G. Booth, when at Clyno.

|

My engineering career began in 1912, when I joined

The Clyno Engineering Co. of Wolverhampton, as a draughtsman. In

1922 I became Chief Engineer and held the position until the

Company went out of existence in the early 1930's during the

trade slump which claimed so many victims at that time. That was

followed by three years from 1932 as co-Designer and Engineer

with Singer Motors, Ltd., who by a happy coincidence have now

become part of the Rootes Group. |

| Finally, early in 1935 I joined Humber, Ltd., as

Chief Engineer, responsible to the Group Director for the design

(excluding bodywork) of Humber, Hillman, and Sunbeam Talbot

cars, and military vehicles, a position held until recently when

I was appointed Chief Consulting Engineer to the Rootes Group.

Thus, my career has been divided roughly into three periods; the

first with a young and enterprising company, which like many

others was unable to weather the economic blizzard of the 1930s;

and the second and third periods with two of the earliest

producers of cars in Great Britain. |

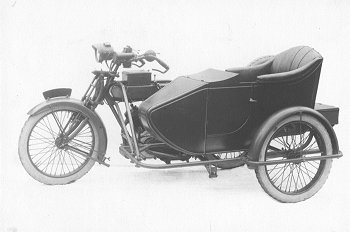

| The first ten years with The Clyno Engineering Co.

included car and aircraft engine design and planning, but the

greater part was on motorcycles, from small two-stroke models to

large and powerful 6- and 8-h.p. twin-cylinder side-car

combinations, which were at that time a very popular mode of

transport. Speaking with some experience, I can say that

motorcycle design as I knew it was at least as intricate and as

technical as that of cars and aero-engines. I found that the

subjects of engine performance, suspension, roadworthiness,

weight reduction and cost, were quite as important as in cars,

and whereas in the latter we worked in three dimensions, a motor

cycle was virtually in two dimensions in a plane of very little

thickness with space limitations and very fine clearances. I can

only compare it with hanging everything on a very short clothes

line! |

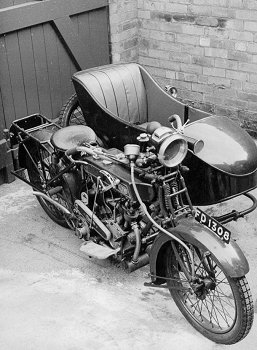

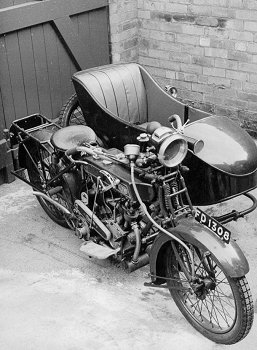

A Clyno combination that belonged to the

Booth family. |

The cover of a Clyno booklet from 1913. It

shows a Dragonfly engine on the top left, a Vickers-Clyno

machine gun carrier on the top right, Fort Works on the bottom

left and Ashes Works on the bottom right. |

I soon discovered the need to consider customer

reaction to every exposed part in terms of appearance and finish

as well as of engineering function, from the engine and other

units right down to the merest nuts, bolts, wires, and clips. As

an enthusiastic motorcyclist, I developed something of a flair

for engines, and to my joy I found a considerable amount of this

type of work coming my way on two-stroke and four-stroke models.

It must be admitted that apart from the economic value, I had no

great liking for the two-stroke engine but its construction was

so different from that of the four-stroke that it added a touch

of variety to my duties. |

| The latter half of that first period, in which I

was made responsible for the design and engineering of the Clyno

cars, presented altogether new and at first unfamiliar problems.

It was not a case of modifying an earlier vehicle with years of

experience behind it, but of starting from scratch and

developing an entirely different line of business. Management in

those days expected the designer to know his job and to do his

development work on the drawing board, with only a small amount

of experimental work. |

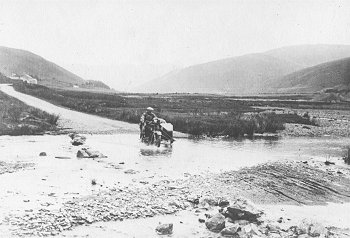

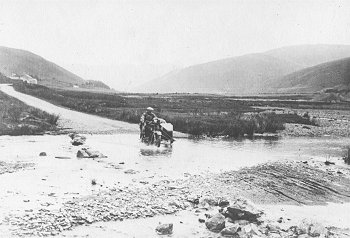

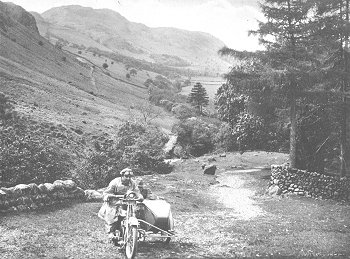

A Clyno combination.

|

|

Out in the wilds with a Clyno combination.

|

Perhaps it was fortunate therefore that our

experience was gained in the first two years on a relatively

small, but rapidly growing, output. Owing entirely to the hard

work and enthusiasm of a very small team of engineers and

production men, the first prototypes were in the Motor

Exhibition of 1922 within four months of the commencement of the

project. |

| That achievement, from a zero start, included the

design and manufacture within the factory of every unit on the

chassis, except the well-tried and excellent 1,368 cu. cm.

Coventry Climax engine which was fitted. When we were fully

geared for volume production our output reached very high

figures for those days, and by 1930 a total of approximately

50,000 cars of all types, of a rating from 9-13 h.p., had been

produced. |

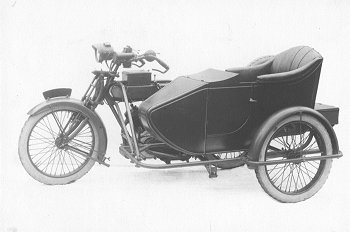

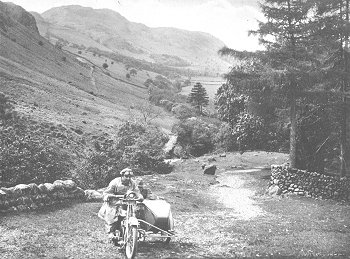

Another Clyno combination in the Lake

District.

|

|

The 1914-18 War Period

On the outbreak of war all preparations for

the manufacture of a Clyno motor car, on the design of which I

was engaged, were suspended, and that particular car project was

abandoned for all time.

|

|

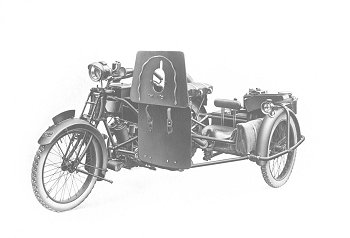

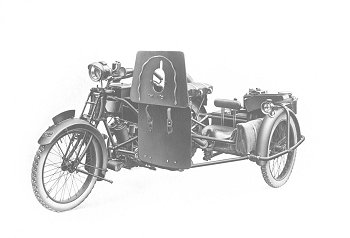

A Vickers-Clyno machine gun carrier.

|

In collaboration with Vickers, Ltd., we designed

and produced mobile machine-gun equipment carrying driver,

gunner, machine gun, armour, and ammunition, on a modified

version of the Clyno motorcycle combination. Its rugged nature

and case of manoeuvre made it highly suitable for active service

in the field, and many were supplied to the British and Russian

forces. |

| A Vickers-Clyno machine in

action. |

|

|

Earl Haig inspecting the

Vickers-Clyno troops. |

| Vickers-Clyno troops in

action. |

|

|

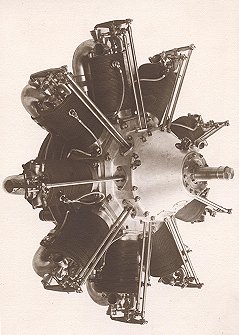

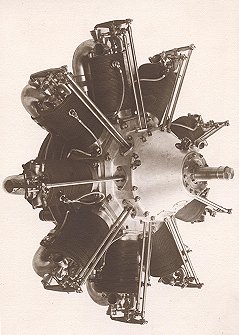

A Dragonfly aero-engine.

|

With the Vickers-Clyno equipment well established

in the factory, our attention was then turned to other wartime

priorities, and we were soon engaged on development contracts

for new type aero-engines, one of which was in collaboration

with Vauxhall Motors, Ltd., for a large water-cooled

twelve-cylinder V-engine. During that period I was privileged to

work under the direction of the late Mr. L. H. Pomeroy,

President of the Institution of Automobile Engineers for the

Session 1934-35, and of Mr. C. E. King, who was in charge of the

project throughout the design and prototype stage, and who later

became Engineering Director of Vauxhall Motors, Ltd. My most

interesting memory of that engine was the design for the

fabrication by welding of the cylinders, complete with

hemispherical head, overhead valve ports, and water casing, all

from steel billets and pressings, and I learned from that

experience that for those methods there was no future in the

automobile industry. |

| Unfortunately, the engine was abandoned and

valuable time was lost, but the knowledge gained proved very

useful for the work which followed.

We were next engaged, with other companies, under the

parentage of the Sheffield Simplex Motor Works, Ltd.,

on what I believe to be one of the first aero-engine shadow

schemes for the manufacture of the 300-h.p. 'Dragon-fly'

nine-cylinder air-cooled radial engine, from the prototype stage

to large-scale production of the complete unit. |

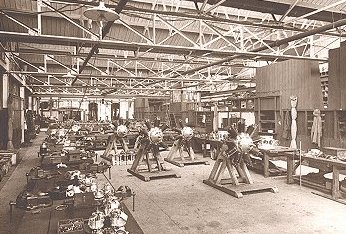

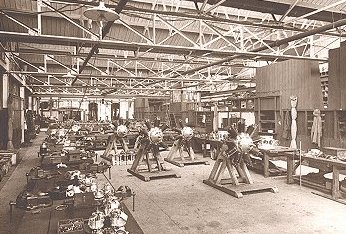

Dragonfly engines in production at Pelham

Street.

|

|

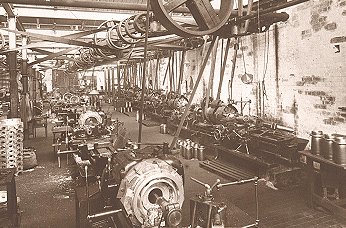

Machining Dragonfly engine blocks.

|

As a member of that planning team I was fortunate

in having as colleagues two lifelong friends, Mr. S. C. Poole,

to whom I owe some of my early training, and our esteemed member

of Council of the Automobile Division, Mr. C. M. van Eugen. That

was my first experience with production planning, which was put

through in record time and detailed to an unusual degree because

of the link with other factories, and I mention it merely to

show what was done forty years ago. |

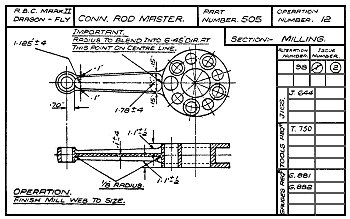

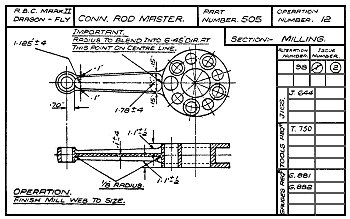

| I have not seen these methods used elsewhere,

probably because they are somewhat laborious. The components

were planned stage by stage from the raw material to the

finished article, each successive operation being represented by

a small-scale drawing, appropriate to its immediate shape and

machining dimensions, and bearing references to gauges, jigs,

and tools, which were detailed at the same time, or to

particular heat treatment or other operations. |

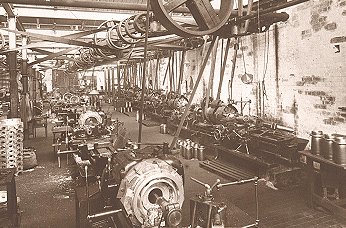

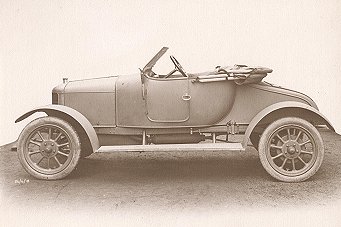

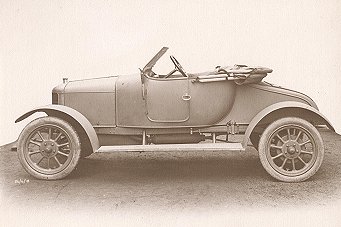

The prototype Clyno car.

|

|

A small-scale drawing of a Dragonfly

connecting rod in readiness for the milling operation.

|

The design of the engine for production purposes,

the planning of the equipment and machine loading, and the

interchangeability of the parts which we achieved, would do credit to

more modern times. Until then interchangeability within very fine limits

as we understand it today, had not been one of our strong points, but

wartime activity greatly accelerated the development of methods for

higher production and greater precision, from which the automobile

industry was to benefit in the following years.

|

| If all this seems commonplace today, it must be

remembered that in 1914 there was little experience of the of

aero-engines in Great Britain, and we certainly had none in The

Clyno Engineering Co., but as a result of the needs of war we

entered the years of peace better equipped to meet the demands

that were to come in the 1920's.

Some Engine Developments |

| In my experience the advances in the design of British

automobile engines from 1920 onwards have been steady and as progressive

as in any other section of car design, and more impressive than is

generally realised. Principles of operation and construction are very

similar but the improvements in detail, materials, performance and

efficiency have been considerable. Much of this is due in no small

measure to the research carried out by Sir Harry Ricardo and others,

whose services to the industry have been of incalculable value. On the

production side, there have been striking changes in methods, processes,

and in accuracy of manufacture, particularly in the last ten years. |

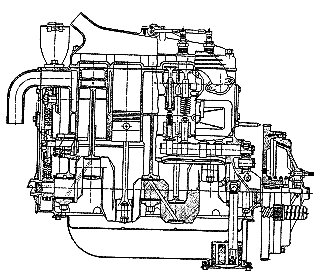

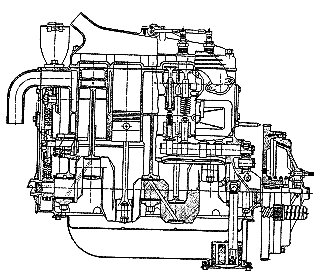

A Clyno 4 cylinder 1,600 cu. cm. engine and

clutch.

|

Another view of a Clyno 4 cylinder engine from

1927. |

Some may deplore the change from the personal skill of

the operator to that of the production machine, but it is only by these

means that quantity production can be maintained without loss of

quality. That skill of the operator exists today in much greater

abundance than ever before, but it has been transferred from

manufacturing operations on the product to manufacture of precision

production equipment. Reverting to the design of the products in which I

have been interested, I have selected one or two items for general

comment. For Clyno cars a number of four-cylinder side-valve engines up

to 1,600 cu. cm. capacity, were manufactured by the Company or

exclusively for them by Coventry Climax Engines, Ltd., to their own

designs and those of The Clyno Engineering Co., under an excellent

arrangement which gave full consultation on matters of design and

manufacture. |

| Those engines progressed through all the normal

developments of the time, including early changes from ball and roller

bearing main journals and splash lubrication to plain bearings and

pressure lubrication, from cast iron to aluminium pistons, and from two

to three bearing crankshafts, all of which had a considerable effect on

the efficiency and smooth running of the engines.

By today's standards the cone clutch was not good but it gave

reasonable service, probably because in those days we had not

arrived at flexible engine mountings. A point of long standing

interest on all Singer engines is the chain-driven overhead

camshaft, which dates back in thought to 1912-13, when it was first

introduced on the prototype Clyno engine by the chief car designer,

Mr. S. C. Poole, with results that were so encouraging that he used

it on the new engines he designed when he joined Singer Motors,

Ltd., in 1920. The design was still very much the same when I joined

the company in 1933, and has given such good service throughout the

years that it has been retained to this day. As a junior member of

the staff on the 1913 design, I well recollect the element of doubt

we had when we introduced the overhead camshaft vertical chain

drive, I think for the first time on a British engine, using a

Coventry 'Duplex' roller chain with external adjustment. It is such

experiences that have justifiably established the roller chain on

British engines against the competition of the inverted-tooth chain,

the helical spur gear, and other forms of drive.

Transmission Developments |

| While developments throughout the years in other

sections of automobile design have followed a reasonably progressive

pattern, I consider those of the transmission have received more thought

and caused more disappointments than all the others put together. In the

1920's when straight spur gears and 'crash change' were usual and gear

changing was an art considered to be the accomplishment of the good

driver, there was relatively far more reason for criticising the lack of

progress than there is today. That state of affairs persisted in most

British designs at least until 1930, and I am sorry to say that for the

Clyno cars I was more concerned about the prevention of tooth chipping

by metallurgical processes than by a new form of gearbox to simplify

gear change. Strangely enough, our main concern was not about the design

of the gearbox, but where to locate it, and what type of propeller shaft

to use, the latter providing the greatest difficulty. No proprietary

types of propeller shafts were available in those days, and as we had no

experience in the manufacture of the open type we decided on the

well-established practice of torque tube and enclosed shaft drive, with

the gearbox mounted at the front and the axle at the rear of the tube. |

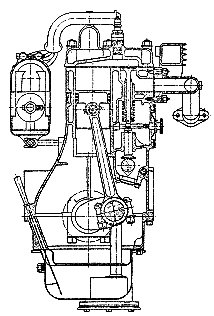

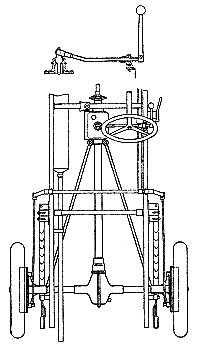

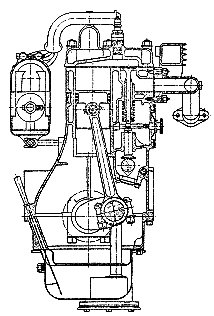

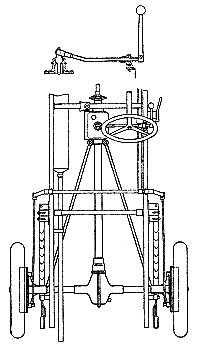

Clyno torque-tube transmission and control. |

|

As the whole transmission unit was anchored to the frame cross member by

a large ball and socket arrangement on one side of the front of the

gearbox, there were problems of gear-lever movement due to swing of the

axle, while at the same time we were asked to meet a popular demand for

right-hand gear control, both of which were dealt with in the simple

manner shown. The drive from the engine to the gearbox was completed by

a short shaft with flexible Hardy couplings, the use of which in that

application proved quite satisfactory with a mechanical centring device.

In my opinion the outstanding development of those early years was the

production in Great Britain, from 1927 onwards, of the Hardy-Spicer

open-type propeller shaft with fully-sealed mechanical joints. That

solved a long-standing problem and made obsolete the type of drive used

on the Clyno car, while at the same time opening the way for the more

general use of unit construction of the engine and gearbox. I have

referred to the lack of improvements in transmissions during the 1920's,

and in my view the growing popularity of the motor car in that period

forced the pace during the 1930's when many progressive changes in

gearing took place, including the so-called silent gearboxes with

constant mesh helical gears using sliding dog engagement, which were

later superseded by different types of syncromesh.

Brake Developments

|

|

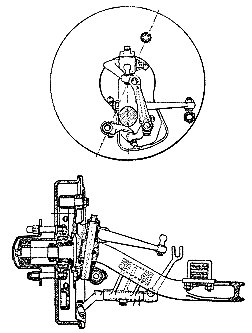

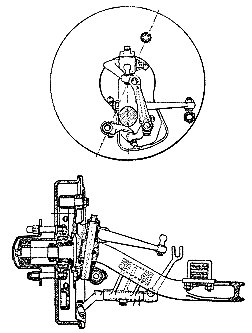

Clyno front wheel brakes, 1924-29.

|

It is my experience that until the last few years there

has been very little difficulty in maintaining the power and efficiency

of brakes to meet the requirements asked of them by improvements in

other parts of the car, but lately the demand for further increases in

power and speed, mainly in the more powerful vehicles, has taxed all the

designer’s efforts, particularly with modern styling.

From 1922 to 1925 the cars with which I was concerned had braking

on the rear wheels only, a feature which was common to the majority

of cars. A parking brake on the transmission was often used, but

most cars had twin rear brakes side by side in drums of considerable

width, linked respectively to the hand and foot control. In order to

avoid drum distortion and minimize the weight we departed from this

method by using narrow drums with two pairs of shoes interlaced on

the Timken principle and mounted on short pivots with cams set at 90

degrees to each other. |

|

It may seem strange to those brought up on

four-wheel braking that we should be satisfied at one time with rear

brakes only, but speeds were relatively low and as cars were few in

number there was little traffic congestion.

In 1924 for the first time on Clyno cars we offered

front wheel brakes as an optional extra at a low price, but buyers were

wary of the skidding problems that might be created and there was not

much sales response. However, by 1925 with twelve months' satisfactory

experience, front wheel brakes were standardised on all models, and we

were so convinced that it was the right thing to do that we adopted

12-inch brakes on the front and 10-inch on the rear with a 55/45 ratio.

That was a lavish- specification for 11- and 13- h.p. cars with an

unladen weight of under 20 cwt.

As an example of the reaction in some quarters to

four-wheel brakes, I had great difficulty in obtaining the approval

of the Licensing Authorities for front-wheel brakes on cars for

taxicab contracts, and also encountered a legal objection from New

Scotland Yard on a technical point because we removed the second

pair of handbrake shoes from each rear drum. They were quite

unnecessary with four-wheel brakes consisting of two separate

systems operated by the foot, with limited compensation, and with

the handbrake interconnected to the rear only, in such a manner that

the failure of any part would still leave one full set in action.

Shortly afterwards the wording of the Regulations was amended to put

the matter beyond doubt. The companies using the transmission

parking brake quite naturally took the opportunity of discarding it.

Most firms made their own brakes in those days, and for Clyno cars

we developed a new front axle with our own braking system, the shoes

being operated by a cam with a lever outside the backing plate and

operating immediately below and on the centre-line of the kingpin,

which avoided any interference from the swing of the stub axle. This

type of design gave good service on approximately 40,000 cars, and

was also adopted on a well-known Continental model.

In my view one of the greatest advances in brake

design came with the production in Great Britain during 1927 of the

hydraulically operated Lockheed brake with internal expanding shoes,

which I believe was first fitted by Mr. F. G. Parnell on the Triumph

Seven car of that period, although earlier versions with external

band brakes had previously been used. It is fortunate that that

method of brake control was available before the mass production of

independent front wheel suspension, as apart from its inherent

technical advantages it simplified the designer’s installation

problems, as was amply proved on the Singer and Rootes Group models.

Now this method has practically supplanted all others throughout the

world.

Design for Comfort and

Safety in Car Suspension

|

| No matter how much we may feel that our roads are

inadequate today, we must admit that the surface conditions are

generally good, at least by comparison with those of the 1920's when

there was little thought for the comfort of the few who used them, and

when road engineering was in infancy. Likewise, by today's standard

there was little that could be said in favour of the suspension system

on our cars, yet they became popular despite discomfort for the

passengers.

The weight distribution was all wrong, with engines well back in

the frame, with the rear passengers over the axle, and with little

luggage accommodation except for unsightly luggage racks. I think it

can be claimed with justification that we have progressed a long way

since then. On Clyno cars we used quarter-elliptic springs which had

the advantage of low unsprung mass, until front-wheel brakes

demanded semi-elliptic springs to deal with brake reactions. |

A Clyno logo.

|

| For all the good they did, the shock absorbers could

have been discarded after less than 5,000 miles of service, and there

was little to choose between one make and another. The only real

improvement during that period came in 1924-25 with the change from

small-section high-pressure tyres to large-section low-pressure balloon

tyres, which started a trend in development that has been repeated in

later years. |

|

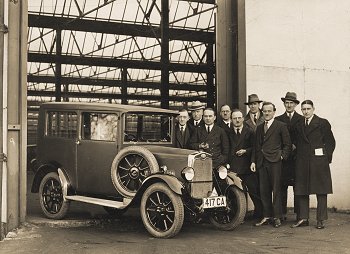

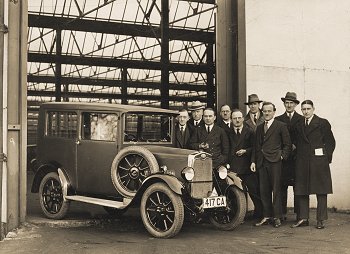

The

new fabric bodied, 2 door Clyno 9 leaving Bushbury Works, with some of

the Clyno staff. 3rd from the right with his hand in his

pocket is Arthur G. Booth himself. Third from the left at the front

(directly above the number plate) is Frank Smith. |

|

Arthur G. Booth in later years. |

|

|

Return to the

previous page |

|