Graiseley Hill Works

|

Beginnings

A.J.S. motorcycles were successful right from the

beginning. Orders poured in, and the company soon became a well known

and successful motorcycle manufacturer, whose reputation was greatly

enhanced by its yearly participation in the Isle of Man T.T. races and

other sporting events. In order to keep up with demand, production had to

be increased. There was no more room in the cramped Retreat Street

premises, and so a new public company was formed with a nominal share capital of

£50,000, to raise the capital needed for a new factory. The company was called A. J. Stevens & Company (1914) Limited, and the

directors were H. Stevens, G. Stevens, J. Stevens (Junior), A. J.

Stevens, E. E. Lamb and E. L. Morcom. The registered offices were at

Retreat Street. The new company soon started to look around for larger

premises so that production could be stepped-up.

The New Factory

Near to Retreat Street, on the corner of Graiseley Hill

and the Penn Road was Graiseley House, which had a large piece of land

attached. It was owned by Richard Evans Willoughby Berrington, a

civil engineer from Berrington, Son, & Martin, Civil Engineers,

Lichfield Street, Wolverhampton. He decided to emigrate to Australia and

so put the house and grounds

up for sale.

|

|

This large piece of land was just what the

company needed, as it was ideally situated, and close to

the existing factory. A.J.S. soon purchased the house and grounds,

and work began on a new 260ft x 80ft factory building.

The building was completed in 1915, and production soon moved

to Graiseley Hill. The Retreat Street premises were initially used

as the company office and repair department.

The directors planned to greatly extend the new factory, but further work was put on hold

because of the war. On 5th November, 1917 the office was

transferred into Graiseley House and the repair department moved to

the new works.

The Retreat Street buildings were then handed-over to Joe

Stevens (senior), who ran the Stevens Screw Company. |

|

After the war, work on enlarging the new factory soon

began. Early in 1919 work started on constructing three new buildings,

each of which was about the same size as the first

building. By the end of 1919 the works covered 109,600sq. ft.

The

buildings were laid out to give a smooth flow of material from the goods

receiving department at the north side of the site, to the despatch

department at the southern end. The original building became the main machine

shop, with the machines operated from overhead line shafting.

Building work continued, and by the autumn of 1922

the factory covered almost 167,000sq. ft., growing to almost

230,000sq. ft. by 1924.

The factory from Graiseley Hill.

Courtesy of Ray Jones.

| The following brief description

of a visit to the factory is from

"The Book of the A.J.S." by W. C.

Haycraft, published in 1927: A

visit to the works of A. J. Stevens

& Company Limited at Wolverhampton,

leaves a very vivid and lasting

impression on the memory, and a very

pleasing one. Mass production is in

evidence everywhere, and the

ingenuity displayed to secure the

same is something to marvel at.

Firstly, one enters the machine

shops, alive with the incessant hum

of overhead shafting and lathes. The

thousand and one parts that go to

make up a motorcycle are here being

shaped to precision by hundreds of

skilled mechanics.

In a well-lighted and spacious

shop adjoining, the engine

components are being assembled and

trued up, and rows of engines are

beginning to take shape. Right in

front of all these are scores of

finished engines waiting patiently

to emit their terrifying screams on

the dynamometer. In another shop the

bicycle parts are under erection,

engine plates being fitted ready to

receive the motors as soon as they

leave the test bench.

In sudden

contrast to all these places, a

visit is now paid to the

sandblasting room, where certain

metal work receives a special

finish. At the entrance is pinned a

warning notice, "DO NOT LEAVE THIS

DOOR OPEN". Slightly opening the

door and peering in, an amazing

sight, almost uncanny, confronts the

eyes. The interior is almost void of

light, caused by dense whirling

steam and sand blocking out all

natural illumination. Amidst this

ghastly atmosphere a weird

phantom-like figure, clothed in what

looks like a diving suit, is bending

over and attending to something that

one cannot define in the intense

gloom. Indeed, this room reminds one

of nothing so much as a place in the

next world, whither some of us are

expected to go. Some of the modern

applications of science are

extraordinary, and grimly

fascinating to watch.

The last of

these shops contains hundreds of

finished motorcycles, which in

rotation are tried out and tuned on

the road by crack riders at

Wolverhampton before being finally

handed over to the Sales Department,

whence they are distributed

throughout the world. |

|

|

An artist's impression of the factory from an A.J.S. catalogue

| Sadly sales fell in the late 1920s due to the recession, and

the company went into voluntary liquidation on 2nd October

1931. The buildings were

put up for sale at auction on Tuesday 5th April, 1932, but

failed to reach the reserved price. The machinery and

contents were sold at a series of auctions on the site

between 5th and 12th April, 1932. The factory buildings were

eventually sold in two lots.

The Southern part of the site was sold to the Star

Aluminium Company Limited, late in 1933. The northern end

was sold to Wolverhampton Die Castings on 17th February

1934. The buildings were sold very cheaply. The total amount

raised from the sale came to

£14,328.7s.6d.

The sales catalogues from April 1932 include a detailed

description of the buildings, departments, and contents.

What follows is based on the description of the buildings,

and the buildings' contents lists in the catalogues.

Graiseley Hill Works Layout |

| 1. |

Graiseley

House, the main office, and the original building

on the site. |

5. |

A brick-built two storey building,

66ft. by 62ft. |

| |

Ground Floor:

Entrance Hall with a time recorder

Enquiry Office and Post Room

Managing Director’s Office

Sales Manager’s Office

Typists’ Office

Chief Clerk’s Office

Secretary’s Office

General Typing Office

ToiletFirst Floor:

Record Office

General Office

Cashier’s Office

Correspondence Office |

|

Ground Floor:

Goods Receiving Department with a large door opening into

Graiseley Hill, and a small partitioned office.

First Floor:

Twelve partitioned administrative offices including:

Buying Office

Drawing Office

Jig and Tool Drawing Office

Small Drawing Office

Wages Office

Costs Office

Buying Office

Director’s Office

Two toilets |

| |

Advertising Office

Tally Office

Export Sales Office

Telephone Exchange

Two toilets

Annexe:

A 78ft. by 22ft. building consisting of

asbestos sheets

on a timber frame, with a boarded floor and boarded

and felt roof, containing:

Stationary Stores

Auditor’s Office

Invoice Office |

6. |

Corrugated Iron building, 425ft. by 66ft. with a basement.

It contained:

Frame and Fork Machine Shop

Frame and Fork Building Shops

Acetylene Welding Shop

Press Shop

Steel Cutting Shop

Tool Store Basement:

Fitting Shop

Steel Stores

Sandblasting Department

|

|

2. |

Garage:

A two storey building with two large garages

(one with an inspection pit) on the ground floor,

with a small room and stores above.

|

7. |

Main Machine Shop,

brick-built, 312ft. by 122ft., with a 30ft. by 15ft.

basement store, and a corrugated iron-built Heat

Treatment Shop. The machine shop included a tool

room, tool stores, gear-cutting section, capstan

lathe section, grinding section, milling and |

|

3. |

Machine Shop

and Stores 113ft. by 67ft. 6inches:

Repair Department

Repair Department Machine Shop

Service Department Stores

Service Department Rough Stores

Service Despatch Department

Service Packing Shop

Four toilets and a wash room

|

|

drilling section, an automatic section,

and a belt shop. There were also nine partitioned works

offices, a partitioned canteen, and the rough stores.

The

Timekeeper’s Office (one of the nine partitioned offices)

contained a time recorder. |

|

4. |

Repair and

Service Departments, and Caretaker’s Accommodation.

A two storey brick building, 113ft. by 27ft.Ground Floor:

Waiting room |

8. |

A brick-built building,

262ft. by 81ft. with a partitioned office, and a

partitioned ambulance room. The office included a

time recorder. The building contained the

Car Erecting Shop, the Experimental Department, and a boiler

house.

|

| |

Enquiry Office with time recorder

General OfficePartitioned Offices: |

9. |

Motor Cycle Erecting Shop

312ft. by 122ft. It also contained a time recorder, the

Engine Test House, a storeroom, and the Saw Mill and Packing

Case Shop

. |

| |

Service Department Office

Engineer’s Office

Superintendent’s Office

Repairs Office

Manager’s Office

First Floor:

A large Stock Room with three small adjoining rooms

Two toilets and wash rooms |

10. |

Despatch

Department, 300ft. by 71ft., with a time

recorder, three partitioned offices, a toilet, and the

following:

Road Test Department

Export Packing Department

Home Packing Department

Commercial Vehicle Office

Despatch Offices

Component Stores

|

| |

Caretaker’s accommodation consisted of

a sitting room, a kitchen, two pantries, a scullery, two

bedrooms, a bathroom, and a toilet. |

11. |

A range of corrugated iron buildings,

361ft. by 90ft. that contained:

Enamelling Shop

Polishing Shop

Small Polishing Shop

Plating Shop, and Chromium Plating Shop

Inspection Shop

Erecting Shop and Sub Assembly Shop

Mudguard Building Shop |

|

|

| 12. |

A garage built of corrugated iron,

48ft. 6 inches by

35 ft. 6 inches with an inspection pit and four pairs

of sliding doors.

|

23. |

Electricity sub-station and switch

room. |

| 13. |

A corrugated iron car shed, 52ft. by 31ft.

|

24. |

Twelve brick-built toilets with

adjoining cycle shed. |

| 14. |

A timber-built Electricians’ Shop and

Carpenters’ Shop. |

25. |

Timber store. |

| 15. |

A corrugated iron lean-to store. |

26. |

Timber store shed, 50ft. 6 inches by

21ft.

|

| 16. |

A corrugated iron incinerator shed. |

27. |

Brick-built boiler house with oil-fired

boiler, and a 4,500 gallon oil tank in an adjoining

brick-built building.

|

| 17. |

Twelve concrete-built toilets with

adjoining cycle shed. |

28. |

Six brick-built toilets.

|

| 18. |

Three concrete toilets.

|

29. |

Oil separator shed, and swarf bins. |

| 19. |

A shed, 56ft. by 17ft.

|

30. |

Fourteen brick-built toilets with

adjoining cycle shed. |

| 20. |

A small office. |

31. |

A timber and asbestos office building

with four rooms and a toilet. |

| 21. |

An office with adjoining shed.

|

32. |

Cycle sheds. |

| 22. |

A concrete-built petrol store with a

1,000 gallon underground tank. |

33. |

A timber and asbestos building, 63ft.

by 16ft. that contained the Staff Canteen, Kitchen, and

panelled Board Room, with adjoining toilet. |

The following section is a

pictorial tour of the factory in ten parts. It contains a large number of

photographs and so may be slow to download.

|

| 1 |

Company Office and Grounds |

| 2 |

Goods Receiving Dept., Raw

Material Inspection, Timber Store, Saw Mill & Case Making

Department |

| 3 |

Boiler House, Machine Shop,

Press Department |

| 4 |

Heat Treatment & Hardening

Dept., Sand Blast |

| 5 |

Bobbing Dept., Tool Room,

Plating Dept., Enamelling Shop |

| 6 |

Engine Test House, Repair

Department |

| 7 |

Frames, Forks, Mudguards,

Wheels, Saddles |

| 8 |

Finishing Department,

Experimental Department |

| 9 |

Road Test Department,

Packing Departments |

| 10 |

The Site in 2002 |

| I would like to thank the late Geoff Stevens for allowing us to

use the old photographs, which are from his collection. |

|

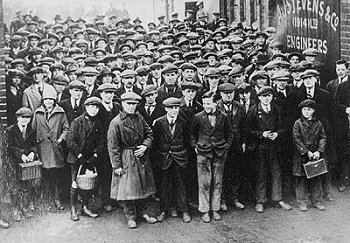

The end of a hard day. Some of the A.J.S.

workforce. |

|

|

|

Return to

A.J.S. factories |

|

Proceed to

Section 1 |

|