|

Modern

Production Methods

Procedure in

a well-known Midland Works

An article published in the January, 1924

edition of The Automobile Engineer

At the present time four distinct types of Sunbeam cars are

being produced, these being their 14, 16, 20, and 24 hp. models. The average

output of the factory is 45 cars per week, rather more than 3,000 work people

being employed. It may be noted that the firm have their own extensive

non-ferrous metal and iron foundries, and also that the coach building,

painting, and finishing departments are very considerable in extent and provide

employment for a large number of persons.

The site on which the works is situated is on the outskirts

of the town of Wolverhampton, and is in many respects ideal. Ample land is

available for future extensions, and in laying out the works there has been no

necessity for cramping, and therefore wide gangways, that assist considerably in

facilitating the transportation of the work through the factory, have been

provided between the various buildings.

Apart from the supply of drop forgings and various

specialised components, such as magnetos, wire wheels, etc., all parts are made

in the works, the factory comprising a self-contained unit. Every precaution is

taken to ensure that the quality of the raw material employed conforms to

specification, and a particularly extensive laboratory, equipped for both

chemical and physical examination, has been installed. When the raw materials

are received from outside sources, the bulk is placed in the stores, and remains

in bond, as it were, until samples, tested in the laboratories, have been passed

as satisfactory. Until the report of the laboratory superintendent is received,

under no circumstances is the raw material issued to the works for production to

be commenced. |

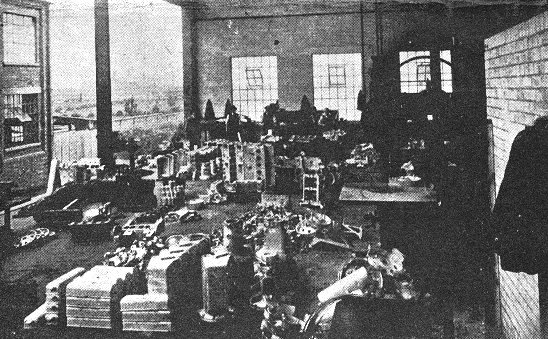

Fig. 1. A general view of the

foundry.

| The foundry, a general view of which is given in

fig. 1, comprises a large and modern building very

efficiently equipped, and which is extremely well

lighted both as regards natural and artificial

means. Moulding machines, of which numerous types

are employed, are used for practically every

operation, it having been found that castings

produced by this means are very much truer to

pattern, and on account of the uniform ramming of

the sand are made with a smaller scrap percentage

than is the case when hand methods are employed.

Both iron and non-ferrous castings are produced,

and, in addition to the ordinary sand castings, the

die-casting process is employed to a very

considerable extent, both in connection with

aluminium and also with aluminium bronze. When

melting aluminium considerable trouble is often

experienced through the corrosive action of the

molten metal on the cast iron pots used for melting.

In order to obviate this difficulty, the Sunbeam

Company coat the interior of the pots with a mixture

of ordinary water glass and whiting, it having been

found that by painting the pots daily with this

preparation they last almost indefinitely. |

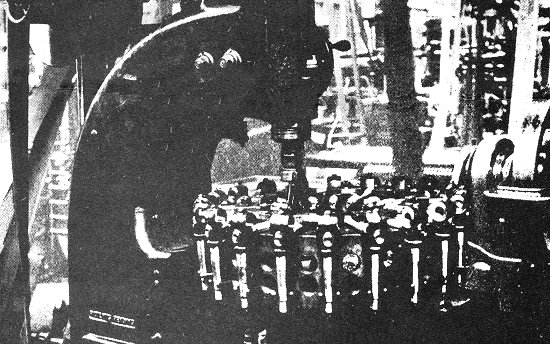

Fig. 2. The fettling shop.

|

Immediately adjacent to the

foundry is an extensive fettling section, a general

view of which is shown in fig. 2. Band saws are

provided for removing the gates or runners, and

pneumatic hammers are employed for chipping

purposes. This department is also responsible for

carrying out the necessary water-pressure tests on

cylinder blocks and cylinder head castings, etc.

As numerous jigs, special

tools, and fixtures are employed for machining

practically every component, the Sunbeam tool room

is naturally an extensive department, and in

addition to the necessary jigs and fixtures, a large

quantity of standard and special cutting tools are

made in this section.

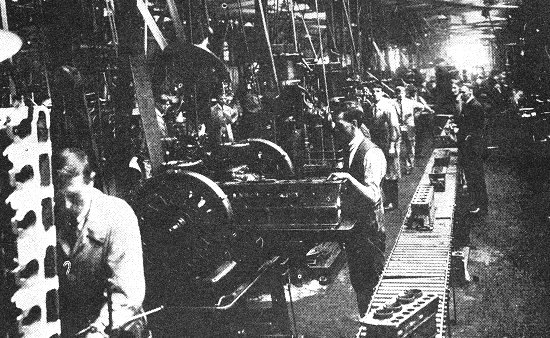

The machine shop comprises a

modern and well equipped department, as may be seen

from fig. 3, gravity operated runways being employed

for the transportation of the heavier components

from one operation to another.

With regard to the layout of

the machines, as far as possible the shop is grouped

in various sections, each of which is completely

equipped for the efficient production of a given

component or unit. For example, fig. 3 shows the

section in which cylinder block castings are

machined. |

Fig. 3. A portion of the runway in

the machine shop.

|

Commencing with the rough

milling operation at one end of the line of

machines, each casting travels along and undergoes

successive operations until it reaches the far end

in a completely finished state. There is no possible

doubt that this arrangement constitutes a most

efficient production method where fairly large

quantities of parts are required, for it reduces the

necessary progress or routine staff to a minimum and

also enables the work of the operation inspectors to

be considerably facilitated.

Practically the only exception

that is made to this method of machine arrangement

in the Sunbeam works is in the case of the automatic

section, where, on account of the highly specialised

labour that is required for setting-up and operating

these machines, it is considered advisable to group

all tools of this class together. It may be

mentioned that the Sunbeam Company operates one of

the largest batteries of Potter & Johnson automatics

in this country, these machines being almost

exclusively employed for the machining of such parts

as gear blanks, brake drums, pistons, etc.

In practically every works a

certain amount of trouble arises on account of the

difficulty of distinguishing one class of steel from

another, after it has left the stores for use in the

works. A widely adopted scheme is to paint the

various grades of steel with distinctive colours in

the form of a strip an inch or so wide extending the

length of the bar. In the course of time, however,

the colours are apt to fade or rub off, and hence

confusion arises. In order to overcome difficulties

of this nature in the works under consideration, a

scheme has recently been introduced by which every

individual piece of bar stock is stamped for the

whole of its length with a distinctive description,

such, for example, as

3 per cent nickel, mild steel, etc. |

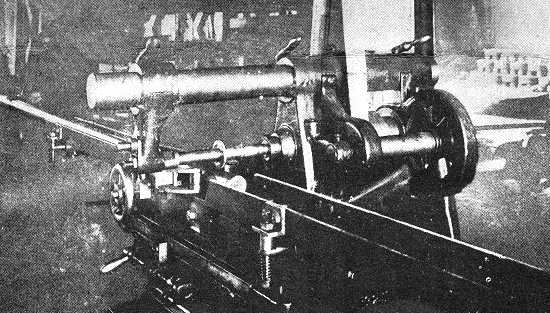

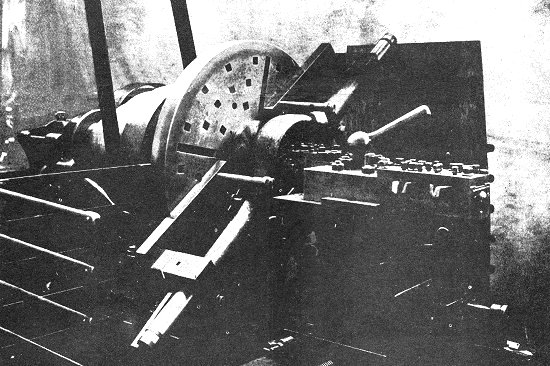

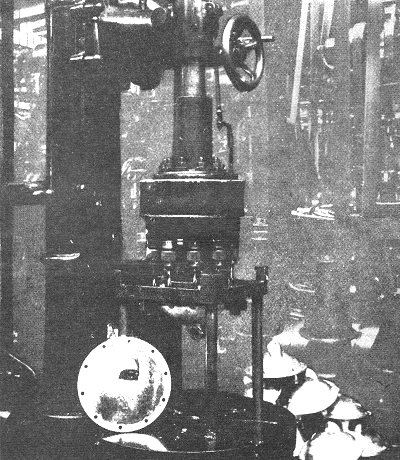

Fig. 4. Stamping bar stock.

|

Fig. 4 illustrates the device

employed for stamping the bars, from which it may be

seen that the stamp, in the form of a circu1ar disc

having the necessary lettering cut on the periphery,

is mounted on the arbor of a small horizontal

milling machine. On the worktable of the machine are

arranged two lengths of channe1 iron, forming an

approximate guide for the bar, which is actually

supported on rollers on the underside, minimising

the friction to the greatest possible extent, thus

enabling the bar to be conveyed along merely by the

rolling action of the circular stamp.

To accurately centre the bars

in relation to the circular stamp, a pair of rollers

located in the vertical plane are provided. These

are operated by a self-centring mechanism actuated

by the hand wheel to be seen in the illustration,

and are closed in on the bar, which is thus

automatically centred. The necessary degree of

pressure is obtained by raising or lowering the

worktable of the machine, and the device is designed

so that it will accommodate all sizes of bars used

in the works.

The water-cooled detachable

cylinder heads are of cast iron, and considerable

care is taken in the foundry to ensure the correct

position of the numerous cores that are necessary

for moulding. In machining, the first operation

consists of milling the lower face to provide an

efficient bearing face and location for the

subsequent operations. |

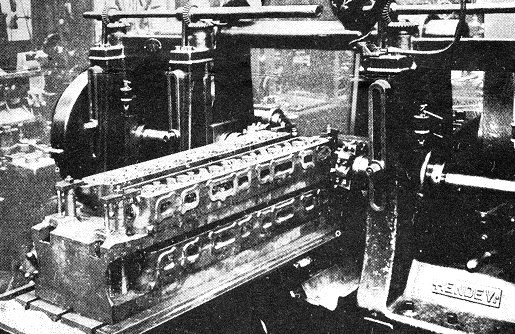

Fig. 5. Milling cylinder head

castings.

|

Next the manifold facings are

milled, and this operation is illustrated in fig. 5.

For this purpose a Hendey double spindle horizontal

milling machine is employed, the cutters being of

the inserted tooth type. As may be seen from the

illustration, four cylinder head castings are

secured in the fixture at one setting, and each

cutter serves to machine the facings of two heads as

the work is traversed past to the cutters.

A particularly simple type of

fixture is employed for balding the work, which,

briefly described, consists of a box shape casting

having two sides only. The work is firmly held in

position by substantial clamps which operate at each

end of the heads. Subsequent operations on the

cylinder heads include drilling and tapping, boring

and facing the valve guide holes and valve seats,

etc. |

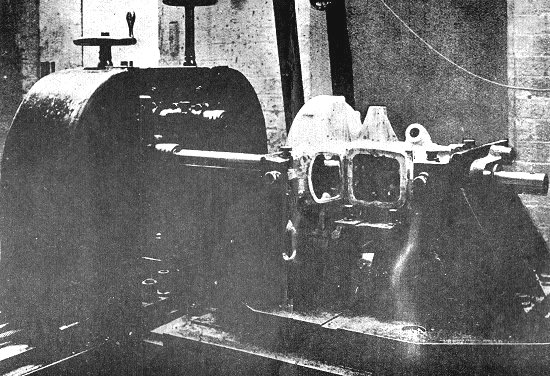

Fig. 6. Boring cylinder blocks.

|

For cylinder boring, a special machine, shown in fig. 6, is

employed, made by Messrs. George H. Alexander & Co., Ltd., of Birmingham. It

will be seen that the machine comprises a horizontal worktable of large area, on

which are mounted the necessary fixtures for locating and holding the cylinder

castings. Four spindles are provided to drive the necessary boring bars, which

are suitably supported at both ends and in between the two cylinder castings by

hardened and ground steel bushings.

It may be noted that provision is made in

the design of the boring machine to enable the centres of the boring bars to be

varied within relatively wide limits, the tool being thus

suitable for practically all sizes of cylinders. After

rough and finish boring, the cylinder blocks, which have previously been faced

on all necessary surfaces, are drilled and tapped and are finally ground in the

bores before passing to the assembly section.

For the milling of the larger aluminium components, such as

crank cases, gear

boxes, etc., multiple spindle Ingersoll milling machines of

the type shown in fig. 7 are extensively employed, The efficiency of these

machines is such that considerable care has to be taken when designing the work

holding fixtures to ensure that the actual cutting time is not exceeded by that

taken for placing the components in position.

|

Fig. 7. Milling aluminium crankcases.

| The operation shown in progress in fig. 7 is that of

milling the upper face of a four-cylinder engine aluminium crank case. The three

cutters are of the inserted tooth type, and are in operation simultaneously, the

centre cutter facing the top of the crank case, whilst the two smaller side

cutters machine the feet. |

Fig. 8. Boring gear boxes.

| For boring gear boxes, the machine and equipment shown in

fig. 8 is employed, from which it will be seen that a fixture of particularly

robust proportions is used to locate the rough casting by means of a number of

adjustable stops. The machine is of the twin spindle type in order that two

boring bars may be in use simultaneously, and the fixture is constructed with

rigid supports for the bars carrying the cutters. After the boring operation has

been completed the faces machined at this setting are utilised as a positive

means of location for the subsequent operations of facing and drilling. |

Fig. 9. Boring and facing rear axle

casings.

|

Sunbeam rear axle casings are produced from steel forgings,

and after the ends of the forgings have been machined in a lathe, the centre

portion is bored and faced by the use of a large centre lathe, provided with

special equipment of the type shown in fig. 9. It will be seen that to the

faceplate of the lathe are secured two angle plate fixtures, which are fitted

with hinged caps that serve to hold the work firmly in place.

Location of the

forging is effected by the use of a positive stop operated at one end of the

forging, as may be clearly seen in the lower portion of the illustration, whilst

one fixed and one adjustable stop make contact with the underside of the centre

circular portion of the axle casing and serve to effect radial location. Two

studs on either side of the centre of the casing carry swinging clamps, and

serve to hold the forging firmly down against the stops, thus preventing either

distortion or chatter whilst the machining operation is actually in progress.

It

will be observed that special multiple tool posts are employed so that in the

first place both flanges of the work are rough and finished bored at one passage

of the boring head, while finally both flanges are faced to width simultaneously

by use of the four tools held in the second post, which are seen in the

illustration.

Considerable use is made in the Sunbeam works of the

continuous rotary method of milling of the parts required for the product. There

is no doubt that where sufficient quantities of parts are required, this scheme

offers the most economical method of production that it is possible to devise,

but where only small batches of work are put through at a time, the natural

complexity and consequent expense of the necessary work holding fixture, renders

this method somewhat uneconomical.

|

Fig. 10. The continuous milling of

change gear forks.

| Both Barber & Colman and Becker vertical machines are used

in connection with the continuous rotary milling process, and in fig. 10 is

shown a machine of the first make set up for facing change gear forks. It will

be seen that the bosses of the components have previously been bored and faced,

and thus a convenient and efficient method of location is provided. The jig

employed, comprises a cast-iron ring on the inside of which are provided a

number of hardened and ground steel plugs, which fit the bore of the

change-speed forks. A series of clamps serve to hold the castings firmly in

position, each clamp operating on two forks simultaneously. Two side and face

cutters are employed, being set to the correct width by means of washers, and it

may be observed that an extra support is provided to the cutter arbor to prevent

any possibility of distortion or springing of the cutter arbor. |

Fig. 11. Milling stub axles.

| A further operation of a somewhat similar nature is shown

in fig. 11, in this case the machine used being a Becker. The parts being

machined are stub axles which have previously been turned, bored, and faced, and

which at this operation require a series of flats to be milled on the shorter

shank.

The construction of the work holding fixture is much the same as that

shown in fig. 10, the work in this instance being located in suitable vees

formed on the upper face of the jig casting, while a number of pins which come

into contact with the longer shank of the work towards the bottom extremities

serve to control the radial setting. In addition to numerous modern and standard types of

adjustable multiple spindle drilling machines, special heads of this type are

extensively used for drilling a number of components. |

|

Fig. 12. A special

multiple spindle drill head. |

Fig. 12 illustrates the head

and fixture employed for the drilling of rear axle

casing covers.

Each drill

spindle, together with the main driving shaft of the attachment, is carried on

substantial ball bearings, the whole of the gearing being enclosed by a suitable

safety guard.

It will be seen that a particularly simple type of work holding

fixture is employed, suitably supported on four pillars or legs raising the work

to a convenient height, and in order that the same fixture may be employed for

drilling other similar parts, which are somewhat longer than those shown. |

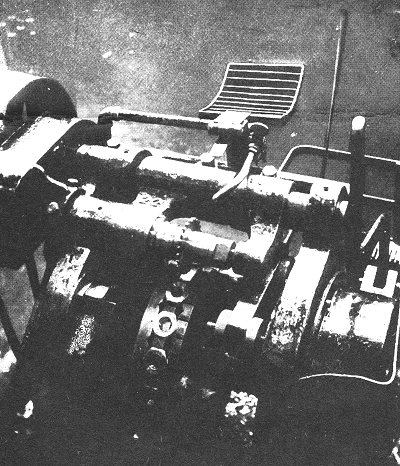

| In fig. 13 is shown a simple yet efficient type of nut

castellating machine comprising a cutter spindle which carries the necessary

slitting cutter for producing the slots.

The cutter spindle is connected by means of

reduction gearing to a shaft carrying a pair of

circular plates that are provided with numerous

serrations on the inside faces in order to locate

and firmly grip the nuts being castellated.

A third disc located between the two gripping

discs serves to provide a positive means of locating

the nuts so that the slots shall be the correct

depth. |

Fig. 13. An efficient nut

castellating machine. |

|

The shafts on which the gripping plates

are mounted are arranged so that their axes are at a slight angle, and when the

nuts are travelling past the cutter they are firmly gripped on account of the

plates being closer together at this point. Immediately a nut has passed the

cutter the plates begin to open, and after a short travel the nuts automatically

drop free of the fixture. As the empty spaces again rotate towards the cutter,

an operator standing in a convenient position places further nuts in position,

and thus the operation is entirely continuous.

To prevent any spring of the gripping plates, two rollers

are provided, which may be seen in the illustration immediately under the cutter

arbor, and these serve to hold the circular plates or discs firmly in position,

and to rigidly grip the nuts.

Great care is taken in the assembly of the various units

that comprise the Sunbeam chassis, and individual tests are carried out in

connection with each engine, gear box, rear axle, etc.

|

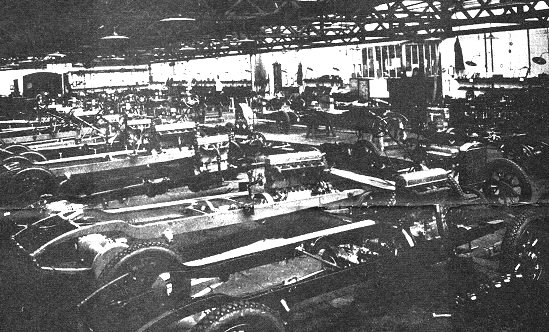

Fig. 14. A general view of the final

assembly shop.

|

A particularly extensive

department is devoted to the final assembly operations, and a general view of

this section is shown in fig. 14. After leaving the assembly shop the completed

chassis undergoes further exhaustive tests on the road, and when these have been

satisfactorily passed, the chassis is handed to the coach building department for

body fitting, painting, etc.

In conclusion it may be mentioned that the standard of

workmanship and procedure generally in the Sunbeam shops is of particularly high

quality.

|

|

Return to

the

previous page |

|