|

This is a sequel to the other article about the factory, and was written about

two years later. It also appeared in 'The Automobile Engineer'.

The Works of the Sunbeam Motor Car Company

Limited

Recent Developments in the Practice of a Well-Known Firm.

A brief description of the

Sunbeam Works at Wolverhampton was given in the

issue of The Automobile Engineer for January, 1924.

Since that date important extensions have been made

to the factory, and in certain directions the

production methods have been improved. Modern plant

has also been installed for gear grinding, as well

as for the finishing operations on pistons, gudgeon

pins, and other parts which call for a high degree

of accuracy.

Originally the company

manufactured several models, but they have now

decided to concentrate on the 14hp. and 20hp. and 3

litre cars. The output of these three types is

approximately fifty per week. In addition, a limited

number of the new 30hp. model are being built. This

car was shown for the first time at the recent Motor

Show at Olympia. It is a particularly fine model,

built on the same general lines as the smaller cars,

except that it has an eight-cylinder engine.

The most important additions to

the works consist of a new machine shop and a

water-raising plant, by means of which an adequate

supply of water for all purposes in the factory may

be obtained if necessary. Few automobile firms

experience any difficulty in this direction, but the

scheme adopted by the Sunbeam Company is of interest as an example of

enterprise in overcoming unusual obstacles. |

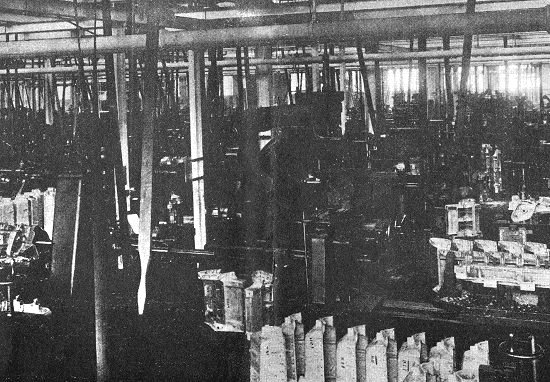

Fig. 1. A view of the new machine

shop.

|

Owing to the high ground on

which the works is situated, and the uncertainty of

the water supply in the neighbourhood, an expert was

consulted as to the advisability of sinking an

artesian well. As the result of this it was decided

to undertake boring operations on the company's

premises, and after reaching a depth of 301ft. an

adequate supply of water was tapped.

The bore hole

passes through strata consisting of conglomerate,

hard red marl, soft red marl, sandy marl, and

sandstone. The lower 200ft. is lined with a steel

casing tube 10in. in diameter, whilst a 12in.

diameter tube is used for the upper portion. In the

portion of the bore which passes through sandstone,

perforated casing tubes are used to allow a free

flow of water. Plain tubes are inserted through the

strata of sandy and soft marl to prevent any

movement which might take place with the soft earth

falling into the bottom of the bore.

The pumping plant consists of a

Broom & Wade air compressor driven by a 30hp.

electric motor in conjunction with two Rees Roturbo

rotary pumps, each direct coupled to a 10hp. motor.

The two rotary pumps have a combined capacity of

24,000 gallons per hour. In addition, a single motor

and pump is installed as a stand-by.

A storage tank is situated in

the pump room at the head of the bore hole, from

which the water is raised by an air and water main

extending to a depth of 170ft. from the surface. The

air pipe is l½in. diameter, whilst the water main is

4½in. diameter, and these are connected together by

a specially designed foot piece, so that the water

is raised by air pressure. From the storage tank the

water is raised to a reinforced concrete storage

tower by the rotary pumps, which deliver through

2,450ft. of 6in. main. The base of the storage tower

is 30ft. above ground level, and it has a capacity

of 30,000 gallons.

To supply the works, the

delivery main from the pump room to the storage

tower is tapped at various points and

connected to the existing pipe line. The

yield from the bore hole varies as the head of water

on the air pipe, being 12,250 gallons per hour with

water at ground level, whilst after twenty four hours'

continuous running the yield was 10,000 gallons per

hour, the water level then being 67ft.

from the surface. A float switch fitted between the

motor starter and the storage tank provides

automatic control of the pump, so that its delivery

shall synchronise with the yield from the bore hole.

It will be apparent that the

installation is quite an elaborate one, and has been carried through with every care

and thoroughness. |

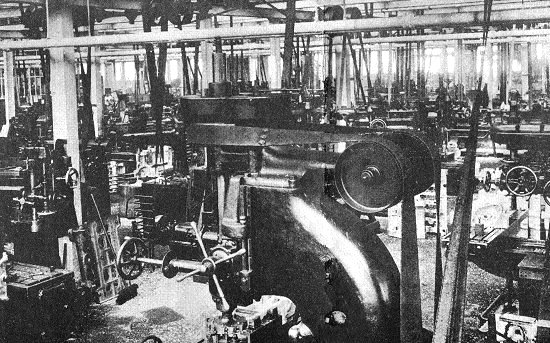

Fig. 2. Another section of the new

machine shop.

|

The new machine shop is a

lofty, well lighted building with a floor area of

48,024 sq. ft. Two views of the shop taken in

opposite directions from a point near the centre are

shown in figs. 1 and 2, though it is difficult to

obtain a photograph showing the full extent of the

shop, owing to the disposition of the machines and

the intervening belts and girders. Incidentally, it

may be remarked as somewhat surprising that more of

the machine tools have not been equipped with

individual motor drives.

An interesting point in the

layout of the shop is the provision of two side

galleries, each of which has an area of 3,312 sq.

ft. These accommodate the lighter units of the

plant, such as small automatics, capstans, brass

finishing lathes, etc. Thus pistons and other

comparatively small parts can conveniently be

produced in the same shop as the larger components. It

may be mentioned that pistons are at present

finished on the outside diameter by grinding,

machines having been installed in one of the

galleries for this purpose. The limit worked to is

exceptionally fine.

On the floor of the new shop,

the heavier plant is laid out as far as possible

according to the sequence of operations. Cylinders,

crank cases, gear boxes, rear axle cases, and

crankshafts are dealt with in this department. A

small section is also devoted to gear grinding. Many

of the machining operations on the larger components

were described in the previous article dealing with

the Sunbeam Works, so that further reference to them

is unnecessary except in cases where the methods

have been revised.

|

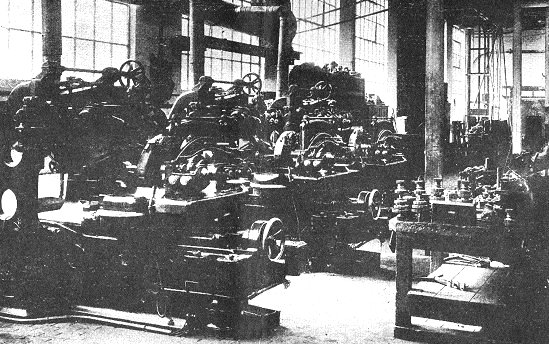

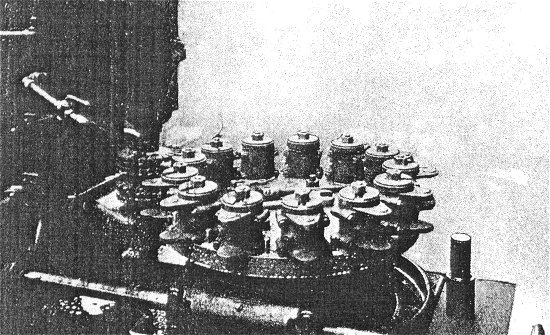

Fig. 3. A battery of Maag gear

grinders.

|

The gear grinding plant is a

comparatively recent introduction, and consists of

three Maag machines arranged as shown in fig. 3.

Apart from the relative merits of these machines as

compared with the Lees-Bradner and other gear

grinders which are being installed by auto mobile

manufacturers, mention may be made of one or two

interesting points in connection with the Maag

machine.

Amongst other things, the use

of small abrasive wheels facilitates the grinding of

cluster gears and such work as that shown on the

table in front of the machines. It is also possible

to employ two wheels for grinding both sides of the

teeth simultaneously, the faces of the wheels being

inclined at an angle equal to the pressure angle of

the gear to be ground. The two faces thus correspond

to the sides of a rack tooth.

Saucer-shaped wheels are

employed, the comparatively heavy wear on the small

wheel face being taken up automatically by an

ingenious electrical device. This consists

essentially of a diamond contact which is advanced

to meet the wheel face at short intervals. As soon

as appreciable wear has taken place, the diamond, in

making contact with the wheel, overshoots a

predetermined point, and in so doing it closes an

electrical circuit, which operates a sensitive

compensating device. This imparts a slight axial

movement to the wheel spindle, which continues until

the wheel face is brought back to its original

position, when the feeding motion is automatically

disengaged. In practice, of course, the movement is

made in very small steps, so that the product is

uniform within the fine limits which are permissible

on this class of work.

|

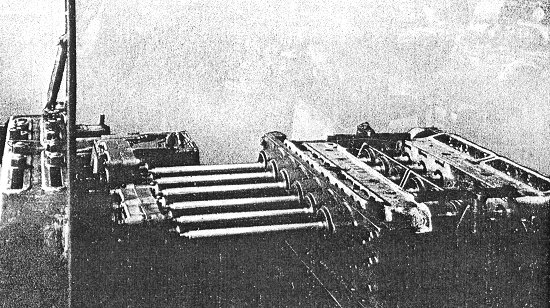

Fig. 4. Boring 20hp. cylinder

blocks.

|

The equipment for handling the

larger components in this shop has in many cases

been designed for dealing with two or more

components at one setting. This applies to the

majority of the milling operations on the cylinder

blocks and cylinder heads, as well as to the

operation of machining the cylinder bores.

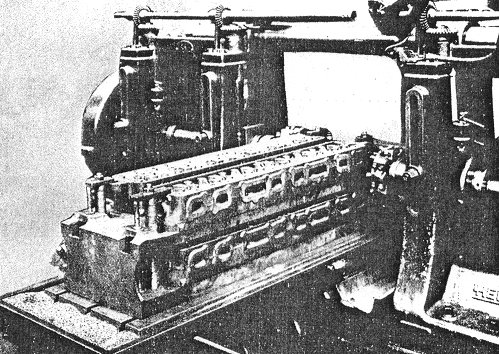

The

machine employed for this operation is illustrated

in fig. 4, the component being the cylinder block

for the 20hp. engine. It may be seen that a fixture

of unusually large size is mounted on the work

table, so that it accommodates two six-cylinder

blocks simultaneously. The machine is one supplied

by G. A. Alexander & Co., Ltd., Birmingham, although

it differs somewhat from their usual range of

cylinder boring machines, having been specially

designed for the work in question.

Attention may be directed to

the massive construction of the fixture, which is

made with a central wall so that the boring bars can

be piloted in the centre as well as at both ends.

Two separate cutters on each bar are employed for

boring both cylinder blocks simultaneously, and the

same machine is used for roughing and finishing

cuts, the bores being finally finished by grinding

on Heald machines.

Another interesting operation

on the cylinder blocks is the milling of the

inspection cover facings. Actually this operation is

carried out prior to boring the cylinders and after

the bottom faces have been milled, Owing to the fact

that the inspection cover faces are inclined to the

vertical, two conical milling cutters, mounted side

by side, are employed for milling the

facings on two cylinder blocks simultaneously.

|

Fig. 5. A multiple fixture for

milling cylinders.

|

Another component on which some

interesting operations are carried out is the

water-cooled cylinder head. This is an intricate

casting, calling for much more careful treatment

than the usual type of detachable head. After heat

treating, the top and bottom faces are finished,

this operation being now performed by surface

grinding in place of the former method of milling

the faces. The bolt holes and valve guide holes are

then drilled at two separate settings on a

multiple-spindle machine, after which the holes are

drilled and tapped on a radial for taking the unions

by means of which the casting is coupled up for the

water test.

A further drilling, facing, and tapping

operation is also carried out on the sparking plug

holes prior to milling the inlet and exhaust faces.

The last-named operation is carried out on a Hendey

duplex milling machine in the manner shown in fig.

5. This affords an excellent example of the type of

multiple fixture employed by the Sunbeam Co. for

handling large components.

The fixture takes the

form of a substantial box casting open at the sides

so that four castings can be milled simultaneously

by means of inserted tooth cutters, which are

sufficiently large to machine the two sets of

facings with one traverse of the work table.

Following this operation, the inlet, exhaust, and

rocker stud holes, as well as the drain hole, are

drilled on an Archdale machine, and the casting is

next transferred to a vertical miller for machining

the combustion chambers. Boring the valve pockets on

a radial then completes the component apart from

testing. |

|

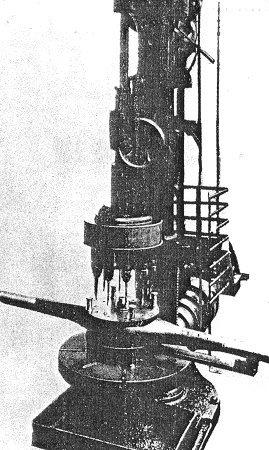

Fig. 6. A typical

multi-spindle drill head. |

Extensive use is made in this

department of multiple-spindle drill heads fitted to

single-spindle machines. One of these is illustrated

in fig. 6, which shows the equipment for drilling

the bolt holes in rear axle casings.

The component

is a steel pressing, which is first of all machined

on the ends, after which it is mounted in a large

face plate fixture for facing and boring the central

portion to take the differential housing.

It should

be noted that, in the operation of turning the

centre, multiple tools are employed, so that both

sides of the casing can be machined at one setting,

thus avoiding the necessity for reversing the work

in the fixture.

The head employed for the

drilling operation is of light construction with

ball bearing spindles, the driving gears being

enclosed in a simple sheet metal casing.

|

|

On this particular component

drilling is carried out from both sides, the two jig plates being clamped in

position by a central bolt and nut, whilst feet are

provided for the fixture to raise it

clear of the work table. The same head is also

employed for drilling the rear axle cover and the

housing which is bolted to the rear axle casing, the

fixture employed in this case being a plate which is

supported on pillars so that the component may be

clamped upwards against the underside of the jig

plate. |

Fig. 7. Milling spring brackets.

|

Another type of tool equipment

which is employed extensively in the Sunbeam works

is the rotary continuous milling fixture. Two

examples of typical operations are shown in figs. 7

and 8, these being representative of a large number

of similar operations on such components as

brackets, forks, small casings and covers, stub

axles, etc. The method is employed to a much greater

extent than in the majority of automobile factories

despite the fact that the number required of any one

component is relatively small. The moderate outputs

are dealt with by making the fixtures comparatively

simple and arranging them so that they can be

quickly changed on the machine tables.

The component shown in fig. 7

is the rear spring bracket and cap, and it will be

observed that a gang of cutters is employed for

finishing both the inside and outside faces of the

two lugs simultaneously. Previous operations consist

of milling the faces of the two halves, milling the

bosses for the bolt holes, and bedding and bolting

up the cap ready for boring. The milling operation

is, however, carried out before finishing the bore.

The components are located in the fixture shown by

spigots, which are a loose fit, whilst the studs

projecting from the base of the fixture prevent the

parts from rotating about the spigots under the

action of the cutters. A substantial bracket bolted

to the column of the machine supports the lower end

of the cutter arbor, thus effectively preventing any

possibility of springing.

|

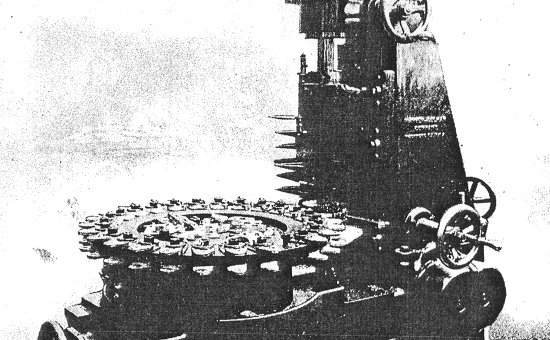

Fig. 8. A typical rotary milling

machine.

| In the case of the component

illustrated in fig. 8, which is the cover for the

brake cam, the fixture is made to accommodate

fifty-two pieces by arranging for the components to

be clamped simultaneously to the upper and lower

side of a projecting flange. A gang of four cutters

is used, as in the previous example, together with a

support to ensure rigidity of the arbor. The

machines employed for this class of work include

chiefly Barber-Colman, Herbert No. 6, and Becker

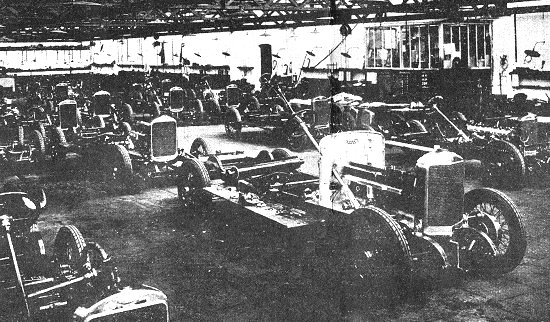

vertical millers. With regard to the erection of the

Sunbeam chassis, no attempt has been made to carry

out the work on an assembly track. Such methods are,

of course, of doubtful value, unless an output

running into hundreds per week can be obtained. In

addition, the firm hold the opinion that the

practice is not applicable to the production of a

high-grade car. Instead, the wheels, complete with

tyres, are bolted in position at an early stage, so

that the chassis may easily be moved along the shop

as it nears completion.

Runways extending throughout

the assembly shop also facilitate the handling of

heavy units. These runways may be seen in fig. 9,

which illustrates one section of the erecting shop.

Separate tests are carried out on the engine, gear

box, and rear axle prior to assembly, whilst the

completed chassis is submitted to a severe road test

before commencing coach building or body fitting. |

Fig. 9. A portion of the erecting

shop.

|

In conclusion, it may be

mentioned that the social side of the organisation

has received its share of attention in the

improvements which have been made, a well-ordered

institute and sports ground having been provided for

the convenience of the Sunbeam employees.

|

|

Return to

the

previous page |

|