| Thompson Brothers (Bilston) Ltd. was founded in 1882.

The company manufactured boilers, galvanised baths, iron or steel

pans and tanks, and items for use in collieries.

The factory in Great Bridge Road, Bilston was originally called

Bradley Boiler Works, but during the First World War it became

Bradley Engineering Works.

An

aviation department was established during the First World War, to produce much

needed aircraft components.

The factory was extended

so that Thompson Brothers could fulfil its military contracts.

The new buildings consisted of three interconnected wooden

buildings with Belfast roofs. These housed sheet metal shops, a wood

mill and machine shops.

An advert from 1896. |

|

|

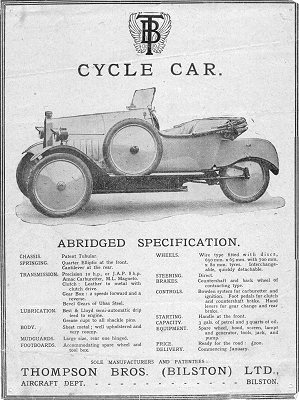

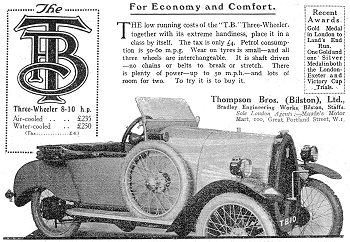

A 1919 advertisement. Courtesy of Peter

Slater. |

When the war ended, so did the Government contracts

and the company was in deep trouble. At the time there was a cycle

car boom and so Thompson Brothers decided to manufacture a three wheeled,

open, two seater, cycle car.

The design was entirely original in concept and combined the

practise of aircraft engineering with motor engineering, using high

standards of workmanship and carefully selected materials. |

| Development work was carried out over a period of 12

months and a prototype model completed a 2,000 mile test, during

which no adjustments or alterations were necessary.

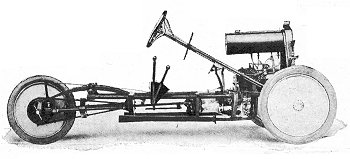

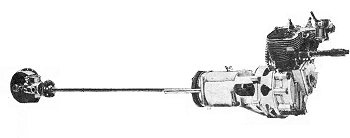

One of the main

features of the design was the engine, clutch and 3 speed gearbox,

which were housed in a centrally mounted unit. It was coupled to the

rear wheel drive by two universal joints. The drive operated the

rear wheel through a set of bevel gears. |

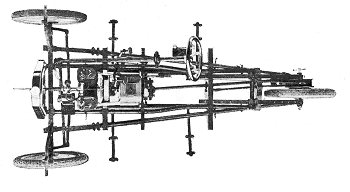

A plan view of the chassis. Courtesy of

Peter Slater.

|

|

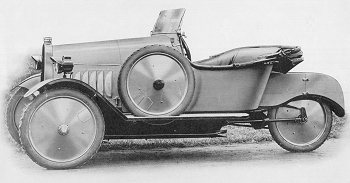

A side view of the chassis. Courtesy of

Peter Slater.

|

The patent tubular chassis was very strong and had a

special rear portion which eliminated the 'roll', 'sway' and rear

wheel canting that were often problems with this type of car.

At the

front was a dummy radiator that formed part of the petrol tank,

which extended over the top of the air-cooled engine. It held 3

gallons of petrol and 3 quarts of oil. |

| The car was fitted with a 10h.p., or 8h.p. J.A.P.

engine, Amac carburettor, M.L. magneto and a leather to metal

clutch. The initial selling price was £200, which included a spare

wheel, hood, screen, horn, lamps, tools, jack and air pump. The

first models were put on display in November 1919 and deliveries

commenced from early 1920. |

The 8h.p. J.A.P. engine. Courtesy of Peter

Slater.

|

|

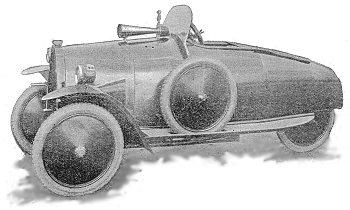

From a 1919 sales leaflet. Courtesy of

Peter Slater. |

Ample leg room was provided in the two seater metal

body. The seats were particularly low and well sprung, which

combined with the efficient springing, provided the utmost comfort

for both driver and passenger. A spare wheel was provided and

carried on the near-side running board. An acetylene generator and

tool locker was carried on the offside running board. |

The specification from the 1919 sales leaflet.

Courtesy of Peter Slater.

|

The sporting model T.B. monocar. |

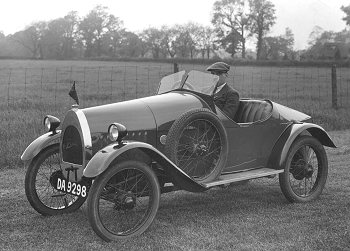

The single seater sporting model appeared in 1920.

It used the same tubular frame chassis as the two seater and was

fitted with a different body. The car was powered by an 8h.p. air

cooled 'V' engine with a 2 speed and reverse gearbox. There

was a shaft drive and centrally fitted steering column. The car was

described as having ample room for the driver and luggage. It was

also fitted with an emergency seat at the rear for an occasional

passenger. |

|

The body was well upholstered and finished in scarlet

and black. The disc wheels added to its sporting appearance. The

company began to take part in competitions and had some success. In

1921 T.B. won the gold medal in the London to Land's End race and

one gold and one silver medal in the London-Exeter and Victory Cup

Trials. The standard two seater had a top speed of 50m.p.h. and all

three wheels were interchangeable. The fuel consumption was 50m.p.g.

to 60m.p.g.

|

An advert from1921.

|

|

The oiling points. Courtesy of Peter

Slater. |

In 1921 an 8 to 10 h.p. water-cooled version was

launched using a conventional radiator. It had a 3 speed and reverse

gear box, an Amac or B. & B. carburettor, Lucas magneto, and a sheet

steel body. Wire wheels were now standard on all models.

The rear wheel could easily be removed in about four minutes

and was interchangeable with the front wheels. It was sprung by

two long cantilever springs which swung on a large diameter

tube. This arrangement together with the patented sub-frame gave

excellent road holding, the car was as steady on corners as most

four wheelers. The air-cooled version sold for £235 and the

water-cooled version was priced at £250. The tax, which was the

same as for a motorcycle, was only £4. By late 1922 these

prices had fallen to £155 and £165.10s respectively. |

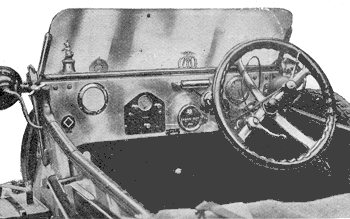

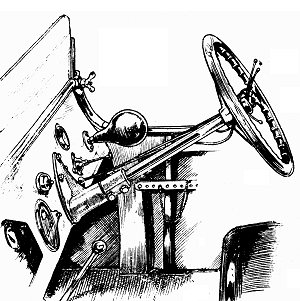

| The steering was of the direct type and was no

harder to steer than a conventional motorcycle combination. The

steering column was stationary with the steering tube inside. It was

mounted on bushes and its quick action gave the driver perfect

control of the vehicle. The steering column was directly linked to

the steering rod and fork ends by a connecting rod and universal

joint. Unlike its modern counterparts it did require frequent

lubrication. |

The steering gear. Courtesy of Peter

Slater. |

|

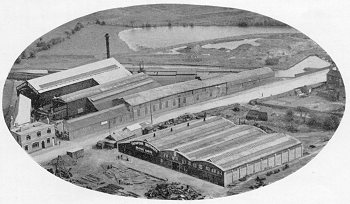

Thompson Brothers works. Courtesy of Peter

Slater. |

The works were situated on the edge of a piece of

disused land which was composed of small hillocks with a few

rough and rutty paths. This area became the testing ground for

the cars and enabled the designers to examine them working under

extreme conditions. There was even a hill with a one in three

gradient, up which the cars managed to climb. |

| The testing and the

subsequent modifications led to a very reliable and high

performance vehicle which could run smoothly in the harshest of

conditions. The cars were run in various competitions and

trials, which were popular at the time. Partly because of the

vigorous testing carried out on the disused land, they were

extremely successful and won 36 gold medals during a period of

two and a half years.

| View a list of

the T.B. competition results |

|

|

|

A T.B. Sports Model. Courtesy of Peter

Slater. |

|

|

The 1922 instrument board.

Photograph courtesy of Peter Slater. |

| The adjustable steering

column.

Drawing courtesy of Peter Slater. |

|

|

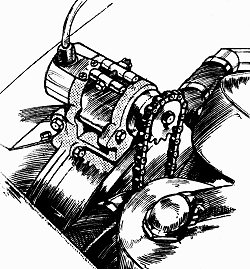

The dynamo. Courtesy of Peter Slater.

|

The Lucas dynamo was carried on top of the

flywheel casing and chain driven from the external flywheel. |

| The starting handle engaged with a sprocket,

carried on the shaft, fitted to the timing cover of the J.A.P.

engine. It was geared up with a ratio of two to one. When pushed

inwards it engaged with the sprocket and rotated the engine. |

The starting handle. Courtesy of Peter

Slater.

|

|

|

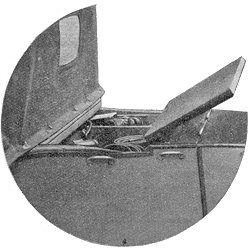

Spares etc. were

accommodated in the locker that was immediately behind the

driving seat.

Photograph courtesy of Peter Slater. |

|

In 1923 production doubled and a good future seemed certain. Four models

were produced in 1924. The water-cooled 'De Luxe Model' sold for £160,

the water-cooled 'Family Model' sold for £162, the water-cooled 'Sports

Model sold for £170, and the air-cooled 'Standard Model' sold for £152.

By 1924 Thompson Brothers had only produced about 150 T.B's. because of

difficulties in obtaining parts from suppliers. |

A 'Sports Model' in operation. Courtesy of

Peter Slater.

|

Cycle cars were initially popular because they were far

cheaper than 4 wheeled cars and cost little to run. By the mid 1920s all

this had changed because the cost of 4 wheeled cars had fallen to such

an extent that they were only slightly more expensive than cycle cars. A

good example of this can be seen from the prices of the locally produced

Clynos. In 1923 a Clyno 4 seater 'Family Model' was priced at £238. By

1925 the Clyno 'Royal' 4 seater was £215 and the 'Royal' 2 seater was

priced at just £210.

Production of the T.B. ended in 1924. A

prototype 4 wheel car was also produced but never entered production.

Because of the production difficulties, the company decided to

concentrate on commercial vehicles and eventually became one of the

world's leading road tanker manufacturers. The company also became known

for its airport fire tenders and became part of the Northern Engineering

Industries Group.

I would like to thank Peter Slater for his help in

producing this section.

|

|

|

|

View some of the T.B.

cars |

|

Return to the list

of manufacturers |

|