|

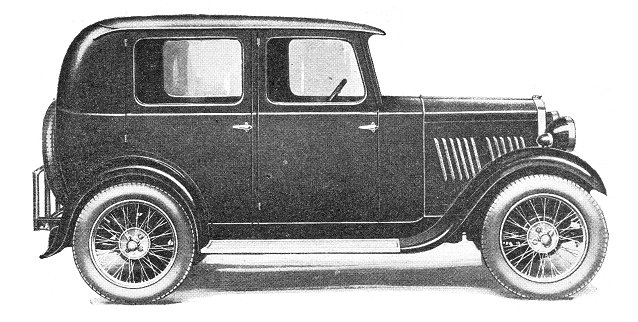

The A.J.S. saloon follows modern lines.

Arduous experimental work and

careful testing have been brought to a

successful issue, and the long-expected A.J.S.

car is now actually being produced. A. J.

Stevens and Company (1914) Limited, is a

progressive firm of the very highest standing in

the motor cycle industry; indeed, only a week or

so ago it again added to its laurels by winning

the Lightweight T.T. race in the Isle of Man.

Hence it is expected that a

small car produced by such a maker will most

certainly be a sound engineering job. The new

car, however, is definitely not intended as a

speed machine. It is the family man’s utility

vehicle, for town work or touring, large in the

body, with plenty of head and leg room,

economical enough in engine size to cut running

expenses down to a minimum, yet sufficiently

powerful to give a good performance without

constant gear changing.

Besides having a good

appearance, the new A.J.S. car has some

individual points: the seating positions are not

too low; there is plenty of leg room; there are

wells in the back floorboards to give even more,

and the instrument board occupies only the

centre of the scuttle, so that tall men in the

front seats are not in danger of barking their

knees.

| The mechanical specification

includes a rigid and compact engine,

with a three-bearing crankshaft,

side valves, and a special form of

combustion chamber which gives power

and flexibility without harshness,

an extra large fuel tank carried on

the back of the frame, half-elliptic

springs, Silentbloc bushes for the

spring anchorages, shock absorbers

for both front and rear axles, a 12

volt lighting set with big headlamps

having electric dip-and-switch

control, wire wheels, furniture hide

upholstery, and chromium plating.

The A.J.S. will be produced first

as a four-seater, four door,

fabric-covered saloon, offered

complete at £230. |

|

Outwardly the car is of reserved aspect with

a good finish, and well-balanced lines from the

chromium-plated radiator, with its central bar

at the front, to the folding luggage grid of

neat oval section tubing at the rear. The wings

are well-domed, fit closely without showing

unsightly gaps above the tyres, and should be

efficient in reducing the need for cleaning to a

minimum.

Doors of more than normal width make entry

into front or rear compartments easy. Separate

front seats with tilting backs are provided, and

with the aid of a spanner they can be adjusted

to any one of four positions. Drop windows will

be fitted to all four doors, the windscreen is a

single panel with an outrigger method of locking

it in position when open, and having screw

clamps to lock it in the closed position. The

vacuum operated screen wiper is carried on the

bottom edge of the screen, which arrangement

gives better vision in rain, and it is

indicative of the care devoted to details that

the suction tubing is of copper built into the

body, and not rubber.

Armrests are provided for

the wide rear seat - the whole body is schemed

with the idea that it will hold four six-foot

men in comfort - the rear window is wide and has

a blind controlled by the driver. Mention has

already been made of the compact central

instrument board; this component is illuminated

by concealed lamps from behind, and includes an

ignition lock as well as a control for reducing

the air supply to the carburettor when starting

from cold. There is also a control within reach

of the driver’s hand for shutting the cork-faced

fuel tap. The fuel feed is by an Autovac, and,

of course, it is an advantage to have the tank

at the back of the car because it can be large,

thus giving a good radius of action without

refilling; in addition, the space in the scuttle

is left free, and there is little likelihood of

a smell of petrol in the body. Incidentally, the

8 gallon tank is suspended at three points on

trunnions and is therefore free from the

possibility of distortion. It has a contents

gauge in the top, close to the filler spout, and

is neatly encased at the back by a

stove-enamelled cover plate.

Advantage has been taken of

the freedom of the scuttle to build into it,

under the bonnet, a really large locker for

tools. One important point in the construction

of the dash and scuttle is that the assembly

forms part of the chassis and not of the body,

so that the body can easily be dismounted at any

time without disturbing any electrical wiring.

Dealing with the mechanical

aspect of the machine, the engine, which

develops 24hp. at 3,000r.p.m. is an entirely new

design of straightforward character, but

possessed of some special detail features. It is

rated at 8.9hp., and comes into the £9 tax

class, the bore being 60mm and the stroke 90mm

(1,018c.c.). The four cylinders and the greater

part of the crank case are cast in one block,

the case being carried down well below the

centre line of the crankshaft, so that the

support for the three main bearings is

particularly stiff. The shaft is dynamically

balanced during manufacture. A pressed steel

sump is employed to close the base of the

engine.

Side valves of special

quality steel are employed, and are operated

through mushroom-ended adjustable tappets of

cast iron, with faces chilled in a special

manner. The combustion chambers are designed in

conformity with the Whatmough principles of

streamline gas flow, the shape being depicted in

one of the accompanying sketches. The result of

this shape is to allow a compression ratio of

5.75 to 1 to be used, thus giving plenty of

power, but avoiding any tendency towards

detonation or ‘pinking’ and giving very smooth

running, besides an ability to pull down to

extraordinarily low speeds without rough

running.

Actually, the car can be driven

up a slope until the engine nearly stops, but

there is no thumping. This means that top gear

can be used almost entirely in traffic, the need

for gear changing, except after actually

stopping, being at a minimum. Great care has

been taken with the cooling system, which is on

the thermo-syphon principal. Water spacing is

given between all four cylinder barrels, and the

valve ports are arranged so that the metal of

their walls is entirely surrounded by water. The

flow enters the block on the valve side, is

graduated to pass evenly around the valve seats

and ports, proceeds afterwards up to the head

and then returns to the large radiator. There

are no thin divisions in the cylinder head

gasket; the head is held down by no fewer than

eighteen bolts, and the general design is

particularly good. Decarbonising should be easy,

and also not often necessary.

There is special interest in the

gas distribution system. The exhaust manifold

has in its centre a pocket to retain heat. This

pocket is carried downward and meets the centre

of the inlet manifold. The gas mixture from the

Solex carburettor plays on to the wall of the

pocket and is warmed, after which it proceeds

through partially insulated pipes up to the

inlet valves. The system works well and gives

that capacity to open the accelerator wide and

suddenly, in order to obtain clean acceleration

away from a low speed on top gear.

Like the rest of the

design, the lubrication of the engine is well

arranged. A gear pump of unusually large size is

driven from the centre of the camshaft. It draws

oil from the big cylindrical filter in the sump,

via a non-return valve, and then delivers it

under pressure through large diameter machined

oilways to the three main bearings and the big

ends, to the three camshaft bearings, and to the

timing chain. The sump contains six pints. A

gauze tray over the sump filters the oil a

second time before it returns into circulation.

The cylindrical filter can be detached downwards

from the bottom of the sump for cleaning

purposes. A dipstick in the side of the sump is

used for testing the oil level, and the oil

filter is placed high up at the front of the

engine.

Returning again to the

moving parts of the engine: the connecting rods

are of nickel steel and have the gudgeon pins

fixed in their small ends. Pistons of special

aluminium alloy have three rings in the head and

a scraper ring. The alloy permits a close piston

fit. At the front of the engine block is a

compartment containing the duplex roller chain,

which provides a triangulated drive from the

camshaft to the camshaft wheel and the dynamo.

The last-mentioned component is mounted high up

in a position where it is accessible, and is

arranged so that it can be swung bodily for

adjusting the chain tension. On the remote end

of the dynamo spindle is a vertical drive to the

contact breaker and distributor of the coil

ignition set.

In a casing at the rear of the

engine is the flywheel, which contains a single

dry-plate clutch. The driven member of this is

radially slotted, and the segments are set

slightly out of plane to give a sweet first

engagement when moving away from rest. Clutch

adjustment is made through a cover plate, there

being set-pins for the purpose in each of the

three toggle arms which control disengagement.

There are six radially placed clutch springs

which are adjustable. Bolted to the flywheel

housing is the three-speed gearbox of normal

design, having a central change, and an enclosed

drive for the speedometer. Oil is filled into

the box through a plug at the top, a second plug

at the side being undone during the process, so

as to prevent over filling.

Drive is transmitted to the

built-up type rear axle through a massive

tubular propeller shaft with a splined

telescopic slide at the forward end, and with

Hardy disc flexible couplings at both ends.

These couplings have ball centring sockets which

are automatically lubricated. Inside the centre

casing of the rear axle is a spiral-bevel final

drive and a bevel differential. Semi-floating

axle shafts are used. The brake drums, both

front and rear, are carried by the wheel bolts,

and are easily removable for inspection of the

shoes - a matter of no small convenience to the

owner. The rear hub brackets and bearings are

also very accessible.

Expanding shoe brakes are

fitted to all four wheels, and are operated

through tie rods and levers. Adjustment is

carried out through an individual setting on

each brake bracket. There is no compensation. To

comply with legal regulations, the front and

rear sets are operated independently, the

right-hand lever applying the rear set, while

the pedal applies the front brakes; but there is

a trip link which transmits the movement of the

cross-shaft of the front brakes to the similar

cross-shaft which operates the rear brakes, the

result being that depression of the pedal

applies all four brakes simultaneously.

There is an unusual type of

steering gear, which in practice proves very

light and pleasant to handle, whilst a fair

amount of caster action makes for steadiness.

The gear consists of a worm mounted on the lower

end of the steering shaft, which passes through

a nut carried in a fork mounted upon the spindle

of the steering drop lever. At the top of the

column is a self-aligning ball bearing. This

gear works very freely; it precludes, however,

the fitting of engine controls at the centre of

the steering wheel, so these controls are very

neatly mounted on the column beneath the wheel.

|

Practically

straight-sided, inclining inwards

towards the front, the channel

section side members of the frame

are stiff, and are braced by four

cross members. The middle members

are attached below the sides and

pass underneath the shaft.

It will be

realised that the detail design of

the car has been carefully thought

out; hence this newcomer may be

expected to render a good account of

itself.

This new car is

on-view at the showrooms of H.

Taylor and Company Limited, 49

Sussex Place, S.W.7. The London

agents. |

|