|

One of

the pioneers of the motor industry

It was the invention of the

petrol motor that made possible the running, on

all the roads of the world, of the

self-propelled vehicle or automobile; and it is,

possibly, with the help of the petrol motor that

the conquest of the air will be achieved. The

making of these motors was in England a few

years ago an unknown industry. When the

automobile was first taken up in this country;

in other words, when a perverse government at

length allowed it to be taken up; foreigners had

gained an immense start in the perfecting of

this engine, and we were dependent upon them for

those we required. Yet the development of the

industry in England has made such immense

strides that it has caught up with and even,

possibly, temporarily over-run the phenomenally

increased demand for the article.

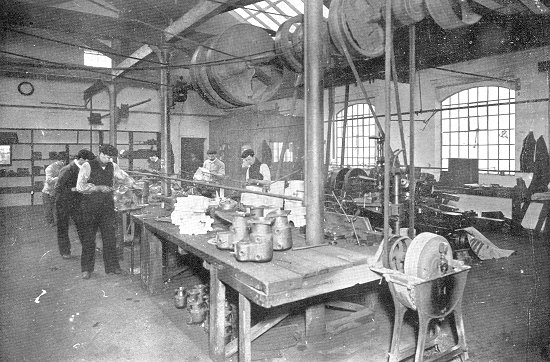

The main shop.

Wolverhampton was not

behind in this new field of industry, and the

first among the firms devoting their energies to

this new branch of manufacture was that now

known as the Stevens Motor Manufacturing Company

Limited, now occupying premises in the west end

of the town at the corner of Pelham Street and

Kimberley Street, and running through to

Merridale Street. The front building contains

upstairs the general and private offices, while

below are extensive stores for finished parts

and fittings, the parts being, where possible,

standardised and interchangeable. Beyond is the

extensive and convenient workshop, with overhead

driving shafts operating the various and usual

engineering tools and machines, among which is

noticeable No. 16 turret lathe by Alfred Herbert

Ltd., the revolving turret being fitted with all

the tools used consecutively on a given complex

piece of work; other lathes, milling, slotting,

drilling and boring machines are there, in fact,

all the necessary adjuncts to an up-to-date and

fully-equipped engineering shop. The power is

derived from a

National Gas Engine in an

engine room beyond, while the oil stores, the

stock-room for the rough castings of iron,

aluminium and other metals, and the testing room

where every engine is brake-tested before going

out, form other departments conveniently opening

out into the main workshop. From 50 to 80 men

are employed, and there is room for more, while

land on two sides will allow for extension when

necessary. The buildings at present cover an

area of 2260 yards and the land on which they

stand is freehold.

A corner of the main shop.

The general run of motors

made by the firm are from single cylinder

bicycle motors to 2-cylinder engines for Cars,

boats, trolleys, etc. A number of 8 to 10hp.

4-cylinder engines were under construction at

the time of our visit. A large part of the

firm's trade is with the colonies, their motors

being recognised as durable and dependable.

One 4-cylinder 16 to 18hp.

motor had just been shipped for use on a launch

on the Nile, while many are fitted to the

trolleys used by railway inspectors in India and

South America.

The Stevens Motor

Manufacturing Co. are now making a portable

petrol engine of special design capable of being

used for manifold purposes such as driving

pumps, dynamos, or other machines, including all

kinds of farmers’ machinery, where they would be

invaluable for working all manner of cutting and

grinding machines. In respect to the firm's work

in adapting the petrol motor to various uses, it

may be said that they have built special engines

for aeroplanes and dirigible balloons, one, the

largest petrol engine turned out in

Wolverhampton, being an 8-cylinder V type motor

for a dirigible balloon. This engine, fitted

with a loose copper water jacket and overhead

valves, though of 120hp., only weighed 500 lbs.

It may be said that now the

general stagnation in the motor trade has passed

away, this firm's prospects are exceedingly

bright, not only for their standard motors for

cycles and carrs, but in view of the development

of the portable engine type and possibly also

the light engine for air machines. The works

offer every facility for the building of

chassis, etc., and, as we have said, are capable

of extension. |