|

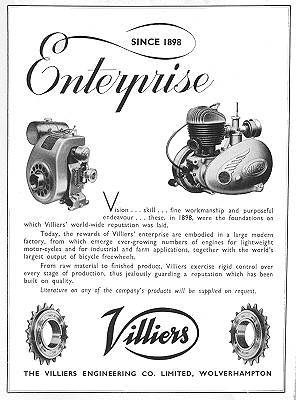

Villiers, the famous Wolverhampton engine

manufacturer, was set up by Charles Marston in 1898. He

was the eldest son of John Marston, of Sunbeam fame.

Villiers was founded to produce pedals and cycle

components for Sunbeam cycles, and later manufactured

the hub gear, and patented free wheel.

Engine production began at the Marston Road factory

in 1911, but initial sales were low, and few were

produced. Their first two stroke engine, launched in

1913, was extremely successful.

Over the intervening years, sales of their numerous

engines remained extremely high. Their two millionth

engine was built in 1956.

Another important factor in their success was the

Villiers flywheel magneto, which was well known all over

the world. |

|

In the early 1960's the company

was taken over by Manganese Bronze Holdings, who

also purchased Associated Motor Cycles (A.M.C.) in

1966. A.M.C. was formed in 1931 when A.J.S. was

purchased by Matchless. In 1952 A.M.C. acquired

Norton Motors Limited who produced Norton

motorbikes. After A.M.C.'s collapse and take-over in

1966, a new company called Norton Villiers was

formed, which would produce machines using the

Norton name.

A new flagship machine was

needed to replace the current ageing models, and so

in 1967 the Commando was developed, just in time for

the Earls Court Show. The first production machines

were completed in April 1968, but there were bending

problems with the frame and so a new frame was

developed, and introduced in January 1969. The

original model, now called the 'Fastback' was joined

by the 'S Type' which had a high level left-side

exhaust and a 2.5 gallon petrol tank.

Initially the engines were

produced in Wolverhampton, the frames in Manchester

and the components were assembled at Burrage Grove,

Plumstead. The Plumstead works were subject to a

Greater London Council compulsory purchase order,

late in 1968 and closed in the following July. After

a Government subsidy, an assembly line was set up in

a factory at North Way, Andover, with the Test

Department in an aircraft hanger on nearby Thruxton

Airfield.

Manufacturing also took place

in Wolverhampton, where about 80 complete machines

were produced each week. Components and complete

engines and gearboxes were also shipped overnight,

from Wolverhampton to the Andover assembly line.

The police were showing a lot

of interest in the Commando and so Neale Shilton was

recruited from Triumph to produce a Commando to

police specifications. The end result was the

'Interpol' machine, which sold in good numbers to

police forces, both at home and abroad. The machine

was powered by a 750 c.c. O.H.V. engine and included

panniers, top box, fairing, and had fittings for a

radio and auxiliary equipment. |

| Right from the beginning the Commando took part in

racing events, and after its win in the 1969 Hutchinson

100 and a second place in the Production T.T., the

company decided to produce a racing model.

This led to the development of the successful 750

c.c. overhead valve 'Production Racer'. It featured a

tuned engine, front disk brake and was finished in

bright yellow, which led to the machine being known as

the 'Yellow Peril'. |

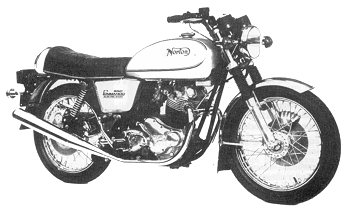

The 750 Commando. Courtesy of the late Jim Boulton. |

|

A new version of the 'S Type' was

introduced in March 1970, called the 'Roadster'. It had

a 750 c.c. O.H.V. engine and a low-level exhaust, with

upward angled silencers and reverse cones. The model 'S'

was discontinued in June.

September 1970 saw the introduction

of the 'Fastback MK. 2', which was soon replaced by the

Mk.3. It had alloy levers and modified stands and chain

guards.

The ‘Street Scrambler’ and the ‘Hi

Rider’ were launched in May 1971 and the ‘Fastback Long

Range’ with a larger petrol tank, was launched in July.

January 1972 saw the appearance of the ‘Mk.4 Fastback’,

an updated ‘Roadster’ and the ‘750 Interstate’, with its

high performance ‘Combat’ engine. The ‘Combat’ could

deliver 65 b.h.p. at 6500 r.p.m. with a 10 to 1

compression ratio. Unfortunately the engine proved to be

extremely unreliable, main bearing failures were common

and pistons tended to break off at a slot, under the oil

control ring. These problems gave the company a bad

reputation, which wasn’t helped by the fact that the

‘Commando’ suffered from quality control problems which

were well covered in the motorcycling press. |

|

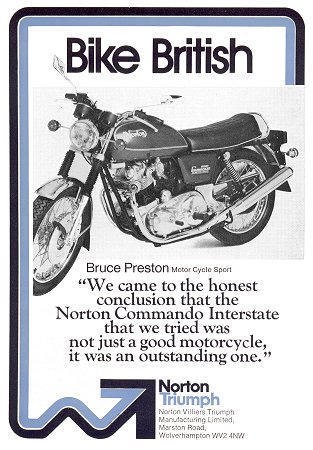

The Norton 'Interstate'. Courtesy of

the late Jim

Boulton. |

By the middle of 1972 the BSA-Triumph

group was in serious financial trouble and the

Government decided to bail the company out with a

financial rescue package, providing it would agree to

merge with Norton Villiers.

This led to the formation of Norton

Villiers Triumph Manufacturing Limited, but the new

company got off to a shaky start. |

|

In January 1973 the ‘Mk.5 Fastback’

was launched and the ‘Long Range’ discontinued. In April

the ‘Roadster’, ‘Hi Rider’ and the ‘Interstate’ all

began to use a new 828 c.c. engine. Development work

also began on a 500 c.c. twin, stepped piston engine,

with a monocoque pressed steel frame. The new engine,

called the ‘Wulf’, was dropped in favour of developing

the rotary Wankel type engine that had been inherited

from BSA.

Things went well that year for the

Norton racing team. Peter Williams won the 1973 Formula

750 T.T. and Mick Grant came in second. Unfortunately

the company itself was in deep financial trouble and

redundancy notices were issued at Andover, which was

followed by a sit-in at the works. The situation

continued to deteriorate in 1974 and came to a head in

June when the Government withdrew its subsidy. There was

a general election and luckily the incoming Labour

Government restored the subsidy.

The company decided to close two of

its sites and concentrate production at Wolverhampton

and Small Heath. This caused a lot of industrial unrest

at Meriden, and resulted in a workers’ sit in, which

stopped production at Small Heath. By the end of the

year the company had lost over 3 million pounds. |

An advert from 1974. |

|

Even during these hard times the

company still managed to produce new models. 1974 saw the

release of the ‘828 Roadster’, the ‘Mk.2 Hi Rider’, the ‘JPN

Replica’ and the ‘Mk.2a Interstate’. Only two of these were

to continue in production the following year. Early in 1975

the company reduced its range of models to just two

machines, the ‘Mk.3 Interstate’ and the ‘Roadster’. Both

machines were improved by the fitting of an electric

starter, a left side gear change, right foot brake and rear

disk brake.

Things went from bad to worse in July

when the Industry Minister recalled a loan for 4 million

pounds and refused to renew the company’s export credits.

The company then went into receivership and redundancies

were announced for all of the staff at the various sites. At

Wolverhampton an action committee was formed in an effort to

continue production and develop the ‘Wulf’ engine. The works

were picketed and a prototype machine called the ‘Norton 76’

was produced. This came to nothing as the Wolverhampton

works never reopened. It was a sad end to such an important

company, and a bitter one. Many of the local workers never

received the money that was owed to them.

Norton Villiers Triumph managed to

survive when the Government stepped in to save part of the

company, but unfortunately this did not include the

Wolverhampton factory. The British motor cycle industry was

in its death throes. The market for British machines

disappeared, there was not enough demand to maintain the

factory. With a strange burst of enthusiasm the company

bought the gates from the now demolished Tong Castle and

erected them at the works entrance in Marston Road. It was

a last gesture. |

| |

|

Read

the history

of the Villiers Engineering

Company Limited |

|

| |

|

|