| Orbit Motorcycles

The company was founded by Mr.

Dorsett

in Sedgley Street, Wolverhampton. He was also involved with the Dorsett, Ford & Mee Engineering Company Limited,

which produced Diamond motorcycles.

The first 'Orbit' machine was

launched in 1913. It consisted of a clip-on engine that fitted

below the bottom bracket of a bicycle, driving the rear wheel

through a friction roller. Only a few were made. Production

ended during the First World War. The first post-war

model appeared in 1919. It was

powered by a 261.5 cc, two-stroke engine, of

the company's own design. It had a belt drive, and sold

for £50. The engine was supplied to other companies, including

Olympic Motorcycles in Green Lane, Wolverhampton. |

|

The 1921 Orbit machine that's in the

collection at the Black Country Living Museum, Dudley.

It is powered by a 261.5 cc Orbit engine. |

| The following is from an article that appeared

in the Motorcycle and Cycle Trader in June 1921.

The ‘Orbit’ Power Unit

Careful attention to detail

characterises the design of the two-stroke engine here described

On the occasion of a recent business

journey to the Midlands we visited the works of Orbit Motors, Ltd., of

Sedgley Street, Wolverhampton, and examined the various component parts

of the ‘Orbit’, 2½ hp. two-stroke, three-port, power unit there

produced. The complete engine is attractive in appearance, being, as is

obvious from the accompanying illustrations, well proportioned, while a

feature which at once strikes the observer is the ample area of the

cooling fins, especially on the cylinder head; this has an appreciable

effect on the efficiency of the unit, for overheating is unknown and a

minimum of plug trouble - an all too-common fault with two-stroke

engines is experienced.

The Large Port Area

The "Orbit" engine has generously

dimensioned ports, thus allowing the gases to gain ingress to and egress

from the cylinder with the utmost dispatch. An unusually large exhaust

pipe, 1½in. in diameter, is utilized, and this is so arranged as to be

free from sharp bends which might restrict the flow of the outgoing

burnt gases. For 1921 a new compression release valve

has been evolved; this delivers the released gases into the main exhaust

pipe through the medium of a steel tube, and thus no oily vapour is

thrown all over the rider's legs when the valve is operated.

Bore and stroke are 68 by 72 mm. (261.

5 c. c.), and the R.A.C. rating is 2.86 hp. Both cylinder and piston are

of close-grained grey iron, and are machined on up-to-date plant and

finally ground to fine limits. The material used acquires a perfect

surface after use and wears remarkably well. For the one-piece

crankshaft, the connecting rod and flywheel, high-grade steel forgings

are used. The reciprocating parts are carefully balanced, resulting in

an almost entire absence of vibration at all speeds. A split type

phosphor bronze big-end bearing has been adopted in order that any wear

at this point may be ‘taken up’ with a minimum of trouble. The

generously dimensioned main bearings are of ‘Richards’ plastic metal,

and these retain crankcase compression for a long period. In order to

enable the inlet port to be cleaned, the induction stump is readily

detachable.

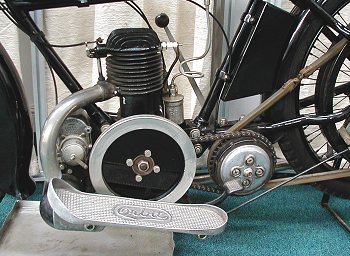

Both sides of the engine showing the

large area of the cooling fins, together

with the easy 'sweep' of the generously

proportioned exhaust pipe. |

Efficiency in Action

As one would expect after a careful

examination of the unit under discussion, it pulls remarkably well on

the road, and has quite a respectable turn of speed. Owing to the large

fins and ports the engine keeps cool even at the highest attainable

speeds, while an excellent feature is that it is not prone to

four-stroking. All the proprietary units, including carburettor,

magneto, and sparking plug, are of good quality, and the unit is

supplied as shown in the accompanying illustrations complete with engine

plates, silencer, magneto and carburettor, ready to drop into the frame.

Immediate deliveries in quantities can be given, and we understand that

the price is reasonable.

|

|

| A close-up view of the 261.5 cc engine

in the 1921 Orbit machine at the Black Country Living Museum. |

|

|

The logo on the side of the Orbit machine at the Black Country Living Museum, Dudley. |

| In 1921 the company launched three machines, the Model A, the

Model B, and the Model C, details are as follows: Model A, a

single speed machine with a belt drive.

Model B, two-speed Burman gearbox, and belt drive.

Model C, three-speed Burman gearbox, and belt drive.

The machines had a wedge-shaped petrol tank, painted black and

lined in gold. They used Swan forks, and a Middlemore's coil and

leaf sprung saddle. The magneto was either a 'baby' Fellows, or a an

M.L., and a Vici, or Cox-Atmos carburettor. Prices ranged from

£36.15s.0d. to £80 for a 3-speed combination with a Charles Hayward

sidecar. The machines sold well and so a stand was taken at the 1922

Olympia show, where four models were displayed; the S23, the BS23,

the OB23, and the BB23. The machines had a new frame with a

horizontal top tube, internal expanding drum brakes on both wheels,

a 3-speed Burman gearbox, and cast aluminium footboards. Details are

as follows:

S23, 261.5 cc engine.

BS23, 350 cc Barr & Stroud sleeve valve engine.

OB23, 350 cc Bradshaw oil-cooled engine.

BB23, 350 cc Blackurne engine.

Sadly sales fell in 1923 due to a trade depression, but hopes

were high, and the company took a stand at the Olympia show. Three

models were on display, two powered by Orbit's 261.5 cc engine, and

one with a Bradshaw oil-cooled engine. They had a three-speed Burman gearbox with chain drive. The oil-cooled machine sold for £60. |

The 1923 two-stroke 'Orbit' from the Motor Cycle

magazine, 16th November, 1922.

|

In 1924 there were three machines on offer, the T.S. 24, the O.B.

24, and the T.S. 12.

The T.S. 24 used the company's 261.5 cc engine, had a two-speed

Burman gearbox, and a chain and belt drive.

The O.B. 24 had a 349 cc Bradshaw engine, a six-speed Burman

gearbox, and a chain drive.

The T.S. 12 had the company's 261.5 cc engine, a twelve-speed

Philipson gearbox, with a primary belt drive, expanding pulleys on

the engine, a countershaft to give twelve speeds, and a chain final

drive. |

The 1924 T.S.12 'Orbit' with the twelve-speed 'Philipson'

gear.

Sadly sales didn't improve. Early in 1924 production

ended, and what remained was sold to Mr. E. Morse, 65 Ranelagh Road, Wolverhampton, who continued to

supply engine spares. The factory was later used for the

manufacture of Diamond motorcycles.

|

| I would like to thank Ray Jones for his help in producing

this section. |

|