| Sunbeamland

Early History

Jeddo Works was situated at the end of

a small track off the Penn Road. The buildings were acquired by

Edward Perry, some time before 1842. Perry began his career as a japanner

with his father Richard who learned the trade at the Old Hall works, then started his own small business

in Brickkiln Street, before moving to Temple Street. Edward Perry

started his business at 7 Queen Street, Wolverhampton before moving to the larger Jeddo Works, in order to

increase production.

St. Paul’s Church was built in 1835, presumably

Paul Street was built at the same time.

Pigot & Company’s 1842 directory lists the

factory as follows, under Japanners: Perry, Edward (& fancy

Pontipool work etc.), Paul Street.

The factory is shown on the 1842 Tithe map, and

identically on Joseph Bridgen’s map of 1850. The maps do not mark

individual building boundaries, only built-up areas. A ‘U’ shaped

area is marked on the site of the works. Part of the area in Paul

Street was occupied by a row of 6 terraced houses behind St. Paul’s

Church, which are clearly marked on the 1885 and 1901 Ordnance

Survey maps. Apart from the houses, the remainder of the shaded area

would have been the factory. |

|

|

|

Jeddo Works, as

seen on the 1842 Tithe map. The image on the right has

the row of houses superimposed. |

|

|

Perry is listed in White’s Staffordshire

Directory of 1851 under Japanware manufacturers & iron and tin plate

workers, as follows: Perry, Edward, Jeddo Works, Paul Street.

Jeddo works was presumably named after Jeddo in

Japan, the site of the Imperial Palace in the mid 19th century.

Jeddo Street is not marked on either the 1842 Tithe map, or

Bridgen’s 1850 map. It is listed in White’s 1851 directory, so

presumably it was built in 1850 or 1851 and named after the works.

Pool Street, originally Tall House Lane was probably renamed at the

same time as the building of Jeddo Street.

| |

|

|

|

|

Read about the Great Strike

at Jeddo Works in 1850-51 |

| |

|

|

The only other building on the eastern side of

Paul Street, on the corner of Pool Street, was Joseph Cooper’s lock

works, which was still there until 1911 when Sunbeamland was

extended into Pool Street. |

|

Jeddo Works after 1877 (based on the 1885

Ordnance Survey map). |

John Marston signed indentures with Edward Perry in 1851 and

served his apprenticeship at the works. Afterwards he purchased

Daniel Smith Lester’s Japanning business at Bilston. Edward

Perry died 1869, and in 1871, Marston purchased the works and became one of

the largest manufacturers of japanware in the country.

The factory was rebuilt around 1877 and new buildings were added.

John Marston Limited produced a wide range of domestic holloware,

including bread dishes, dish covers, pots, pans, kettles, spirit

lamps, foot warmers, and black enamel ware. |

| From the map opposite it can be seen that the 1877 rebuild was

extensive. It seems likely that all of the original buildings were

replaced in the process. By 1881 the company employed 84 men, 41

women, and 19 boys.

The Sunbeam name was registered in 1888

at the time when bicycle production was just beginning at the works.

Around this time the name of the works was changed to Sunbeamland,

a name that remained until the late 1930s, after the Sunbeam name

and products were sold to AMC. |

The original factory superimposed on the 1877

buildings. |

The early Sunbeamland, from the junction of Paul Street

and Jeddo Street.. It clearly shows the 1877 buildings.

|

In 1911 the factory was greatly extended. The

remaining houses in Paul Street, Cooper's Lock Works, and all of the

adjacent buildings in Pool Street were demolished to make way for

the new development. When the work had been completed, the factory

(externally) looked much as it does today, filling the whole of the

east side of Paul Street, and the northern end of Pool Street.

Another building which has now disappeared can be seen in the top

right-hand corner of the photograph below. It stood on the opposite

side of Jeddo Street and was linked to the main factory by a covered

bridge. |

The factory after 1911 with Pool Street on the left,

and Paul Street on the right.

| The next important changes took place in 1934, towards the

end of the ailing motorcycle and bicycle production. The company

had clearly decided to concentrate on building radiators at this

time. Radiator production was very profitable and became the

mainstay of the business. It was decided to mechanise radiator

production in order to increase productivity and profitability.

As a result many of the internal buildings, and one of the

external buildings in Jeddo Street were demolished, and replaced

with the buildings that still occupy the central yard. A small

two storey building in Paul Street was also demolished, and

replaced with an extension to the building at the western end of

Paul Street. It seems likely that at this time the building on

the opposite side of Jeddo Street, and the linking bridge were

also demolished. The factory in

the early 1920s |

An impression of Sunbeamland in the early 1920s.

| The drawing above gives an impression of how the factory

looked in the 1920s, as viewed from the junction of Pool

Street (on the left) and Paul Street (on the right). The

buildings in Pool Street were part of the 1911 development,

as were both end buildings in Paul Street. The two centre

buildings in Paul Street possibly date from around 1900.

The Location of the

Departments |

The buildings in Pool Street.

|

1. Cycle Finishing Shop where all

cycles were built except for 2-speed Golden Sunbeams.

2. Wheel Building Shop under Mr. Arrowsmith where

motorcycle and bicycle wheels were built.

3. Enamel and Polishing Shop run by Mr. Mason. For

general enamelling, lining of frames and petrol tanks, and a lot

of women and girls, pumice stoning, and polishing the finished

frames and forks (along the inside wall above top yard). There

were a number of enamelling vats, and hardening-off stoves

(along the outside wall below the chimneys).

4. Toolroom.

5. Engine and Gearbox Building Shop containing a row of

benches for the building of engines and gearboxes (engines on

Pool Street side, gearboxes on factory side). The foreman of the

engine bench was George Stephenson, who later moved to the

Development Department. He was succeeded by Mr. Robin,

inevitably known as ‘Cock’ Robin.

6. Motorcycle Finishing Shop under Jack Walton, where

the engine was put in the frame, and the motorcycle built and

completed. The inspectors were Harry Higgins, and Harry Idiens.

7. Polishing Shop.

8. General Machine Shop run by Arthur Cowen whose office

was at the Paul Street end of the machine shop. On the top yard

side, by the office was the sandblasting shop. In a small

extension on the inside wall, facing Top Yard, was the Tool and

Gauge Shop.

9. Test House. Tommy de la Hay, Alec Bennett, George

Dance, Albert Collins etc.

10. Canteen. The canteen lady, Nellie, cooked the chops

etc. that you brought-in for your lunch. She also worked in the

factory and started in the canteen at 12 o’clock.

11. Plating Shop (front), Blacksmiths Shop (rear).

12. General Stores for all raw materials, steel, brass

etc. and a small amount of sheet aluminium.

13. Tyre, Inner Tube, & Chain Case Shop, run by Mr.

Mason. |

The buildings in Paul Street.

3. Enamel and Polishing Shop run by Mr. Mason. For

general enamelling, lining of frames and petrol tanks, and a lot

of women and girls, pumice stoning, and polishing the finished

frames and forks (along the inside wall above top yard). There

were a number of enamelling vats, and hardening-off stoves

(along the outside wall below the chimneys).

14. Drawing Office.

15. Main Office. At the Jeddo Street end was the

Managing Director’s (Sidney Bowers) office. Other offices

included the Secretaries Office run by Freddie Payne, the Buying

Office run by Billy Plant, the Buying Office, and the Finance

Office run by accountant Graham Bellingham.

Top Gate in Paul Street led into Top Yard. On the

left-hand side of the entrance was the stairs leading to the

Works Manager's Office, and the Wages Office. On the right-hand

side of the entrance was the time clock for clocking-in, and the

timekeeper’s office. Arthur Fisher was the timekeeper. He

previously worked in the Tube Shop cutting tubes to length.

16. Works Manager’s Office. F. T. Jones was works

manager. The Wages Office was at the back.

17. Development Department.

18. Boiler House. Heating for the factory.

19. Golden Sunbeam building shop for 2-speed bicycles.

The foreman was Mr. Weston.

Bottom Gate led into Bottom Yard and the Radiator

Despatch Department.

20. Motorcycle Packing House. Ernie Deacen Packing

Manager.

21. Golden Sunbeam stores. |

The old building in Top Yard.

|

22. Second Machine Shop run by Mr. Mountford. Known as Mountford’s Machine Shop.

23. Lug Shop. The malleable iron for the lugs came from

Greens in Lever Street.

24. Hatton Jig Department where the lugs were bent. |

The building on the opposite side of Jeddo Street.

|

25. Toolroom.

26. Tinsmiths Shop.

27. Bicycle Handlebar and Brake Lever Building Shop.

28. Brazing Shop. |

The building alongside Jeddo Street, and the building

in Bottom Yard.

|

29. Press Shop (hand presses).

30. Radiator Shop. Two large rolling machines which were

fed from rolls of copper, about 12 inches in diameter and

between 1½ inches to 5 inches wide. The machines produced

lengths of corrugated copper, which was cut to lengths of 3 to 6

feet, and crimped. The lengths were then taken to the girls who

operated small toggle hand presses, which pressed the ends and

lapped them together. There were soldering benches where the

radiator components were placed in a fixture, and dipped into a

solder bath.

31. Maintenance Department manned by electricians, tool

fitters, and building maintenance staff.

32. Pattern Store for tube patterns.

33. Frame Shop. Arthur Fox cut the tubes to length and

scalloped them to fit the lugs, all singly, no press work,

setting them with stick and plate gauges. They were pinned with

one eighth of an inch pegs, and sent to the Brazing Shop in Jeddo Street. Also the General Fabrication Department for petrol

tanks, chain cases etc. George Newman in charge, Bill Smith his

right-hand man.

34. Sheet Metal Stores.

35. Radiator Despatch Department.

A gas engine was near the back of Top Yard.

It drove the machines via overhead line shafting, and was

operated by Dick Corfield who used to cut people’s hair for

threepence a time.

All the lifts were rope-operated. The first

electrically powered lift was installed in about 1928 at the

back of the Pool Street building, in Top Yard.

Every department had an inspector who

regularly checked everyone’s work. Anyone producing sub-standard

work was often sacked on the spot. |

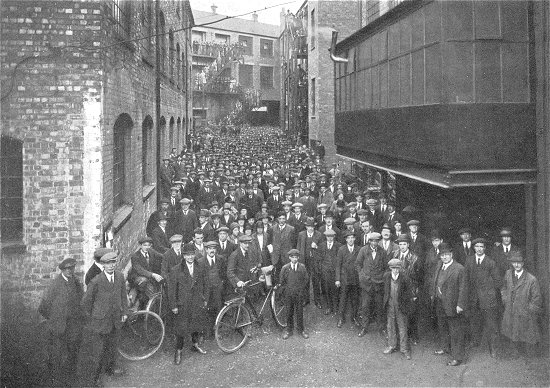

Sunbeam staff in Top Yard, looking towards Top Gate,

in 1928.

Looking towards Paul Street in the late 1960s.

| The photograph above shows the factory in its final form,

when it was owned by C. E. Marshall (Wolverhampton) Limited. The

building on the right acquired a flat roof in the 1934

alterations, when it was extended across the site of a small

2-storey building that was demolished. The 2-story building can

be seen in the drawings above.

During the Second World

War the company manufactured aircraft components, including

radiators, parts

for the De Havilland Mosquito, metal fuel tanks for Wellington

Bombers and other aircraft, pioneered the development of

flexible non-metallic fuel tanks, and self-sealing covers. In 1943, John Marston Limited,

part of ICI Metals Division, merged with another ICI subsidiary, the

Excelsior Motor Radiator Company Limited of Leeds, to form Marston

Excelsior.

An advert from 1954.

The company became one of the country's leading producers of

cooling systems using a wide range of materials including

aluminium and cuprous alloys, uranium, zirconium, tantalum,

reinforced plastics and synthetic rubbers. The many products

included heat exchangers, pressure vessels, pipework, bursting

discs, special purpose machines, industrial fans, flexible tanks

for aircraft, bulk storage, and the transport of liquids. |

In 1967 the factory was taken over by C. E. Marshall

(Wolverhampton) Limited which specialised in diecasting,

electroplating, and general assembly work. The factory closed in

1999 with the loss of sixty jobs, and was acquired by

A. J. Mucklow & Company Limited. The firm leased it to Chubb until 2009

during which time it remained empty. In

August 2009 it was sold to Urban Splash for conversion into small

industrial units and offices. Sadly funds for redevelopment couldn't

be found, and so the property remained empty and in a vulnerable

state.

After many years of dereliction, the factory was finally acquired by

property developer Liam Wordley in 2013, and is now (in 2015) being

converted into around 115 apartments at a cost of about £10 million.

It finally looks as though its future has been secured. |

|

|

Looking up Pool Street in about 2000. |

This photograph shows the factory when it was still owned by

C. E. Marshall. At this time the buildings, although empty, were

in good condition, without a single broken window. Sadly,

after Marshalls sold the factory it rapidly declined. Most of

the windows were broken, and

boarded-up.

By 2009, most of the panels in the front door

were missing, affording easy access to the site. |

| Urban Splash secured the building with metal panels over the

windows and doors which prevented unauthorised access, and

vandalism. Although it became an eyesore, it saved the building

from damage and vandalism, and has allowed today's redevelopment to

go ahead. |

Looking along Paul Street in about 2000. |

|

|

|

|

|

| Return to Decline

and Fall |

|

Return to the

beginning |

|

Proceed to the

list of models |

|