|

Background

It all started when Absolom

Harper and his two sons founded A. Harper & Sons,

ironfounders, at Waddams Pool Works in Hall Street,

Dudley. Absolom’s daughter Mary married George Bean,

a bank clerk who grew-up in Stamford, Lincolnshire,

where he was born in 1855. He met Mary while working

for a bank in Dudley, and soon became financial

manager of Allen, Everitt & Sons of Smethwick. After

their marriage George left his job and joined the

family business. In 1901 he became the principal

shareholder. The name was changed to A. Harper, Sons

& Bean in 1907 when George became chairman. |

|

The business

greatly prospered during the First World War thanks to a

plentiful supply of ministry contracts for munitions.

The factory buildings were extended in order to increase

the production of shrapnel and shell cases. After the war George

Bean received a knighthood for his

services to the war effort, and his only son John, known

as Jack, who also worked in the business, was made a

CBE.

The Bean Car

At the end of hostilities the

lucrative munitions orders ceased and something had to

be quickly found to replace them, so that the business

could survive. At the time motor cars were becoming

increasingly popular, and so the decision was taken for

the company to become a car manufacturer. At this time the jigs, patterns,

tools, and manufacturing rights for the Perry car were

up for sale and so A. Harper, Sons & Bean purchased them

in January 1919 for £15,000 as a way of quickly getting

into the industry by buying a tried and tested design.

The company’s first car, the Bean

11.9, a slightly updated Perry design, was launched at

the 1919 Motor Show.

Harry Radford was employed as Chief Designer to oversee

the initial modifications that were made to the Perry

design, and Tom Conroy, an American production engineer

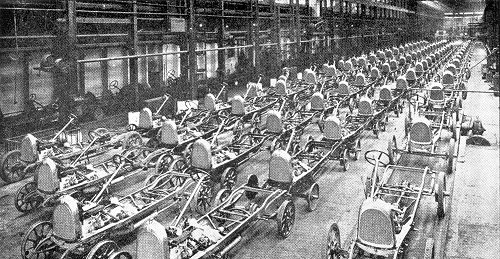

took charge of the Tipton factory. Production began in

earnest in January 1920 and soon 80 chassis were

completed each week, at a newly built factory in Tipton,

using the latest machinery and twin moving track

assembly lines. The

complete car chassis were driven

to the Waddams Pool Works in Dudley for the bodies to be

fitted.

Unfortunately sales were not good, because the vehicles were sold at

a higher price than the competition. Although prices were

slashed, the recession in the car industry in 1920

rapidly led to spiralling debts. A receiver was

appointed, and production ended at Tipton in October

1920. In November Jack Bean resigned from the company.

The 20/25 cwt. lorry from 1926,

that's in the collection at the Black Country Living

Museum.

Rejuvenation

During November 1921 a huge

investment of capital by Sir George Bean, Barclays Bank,

The National Provincial Bank, and Hadfields enabled them

to buy a 55% controlling interest from Harper Bean and

repay the creditors. This allowed A. Harper, Sons & Bean

to manage their own affairs again, but would have

serious financial implications five years later.

Car production started again in 1922,

and slowly increased to 100 cars a week by August. October 1923 saw the launch of a

new car, the much larger Bean 14, powered by a 13.9 hp.

engine, and fitted with a 4-speed gearbox. The engine and

gearbox would prove to be ideal for the company's

first commercial vehicles. |

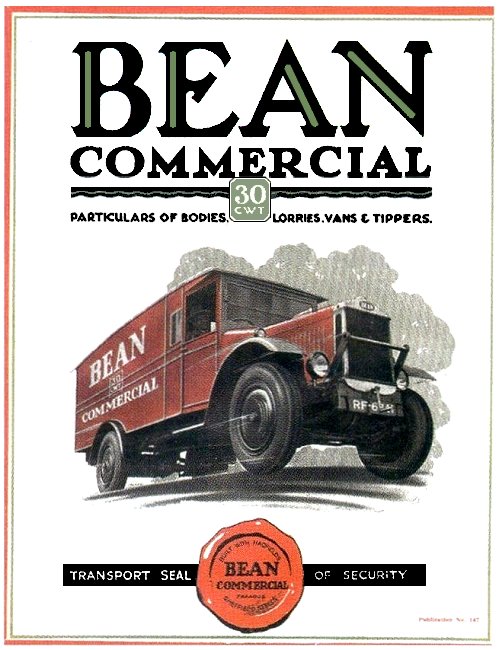

| The Type 'W' 30

cwt. lorry from 1930, that belongs to Daniel

Batham and Son Limited. As seen at the Black

Country Living Museum in 2010. |

|

Commercial Vehicles In November 1924 the company

launched the first Bean commercial vehicle, a 25 cwt.

chassis based on the 13.9 hp. engine and gearbox. The

vehicles mainly appeared as lorries, but vans,

ambulances, coaches and light buses were also made.

The engine and gearbox were mounted on a separate

chassis, and initially, the vehicle only had rear wheel

brakes. The 20/25 cwt. chassis sold for £265. From 1926

front wheel brakes were available for an extra £20.

Unfortunately the company suffered

from an acute shortage of cash, with debts totalling £1.8

million, mainly due to the restructuring in November

1921. As a result Hadfields, the Sheffield steel

producer, rescued the company and renamed it Bean Cars

Limited, in June 1926.

In June 1927 the chassis was replaced by a 30 cwt.

model designed by Hugh Kerr Thomas. It had a 2.3 litre

Ricardo high turbulence cylinder head engine, and sold

for £325. By this time the commercial chassis accounted

for about 60% of the total production at Tipton. |

| The 30 cwt. chassis continued in production until

1929 when it was replaced by the 'Empire' model, powered

by a 3.6 litre Ricardo high turbulence cylinder head

engine.

It only remained in production for about 18 months,

when it was replaced by an updated version of the

original 20/25 cwt. chassis, powered by a 2.3 litre

Hadfield engine.

The new chassis was only manufactured for just over

three months, because Bean Cars Limited went into

receivership on the 19th June, 1931, when vehicle

production ended. The cars had not been selling well,

and soon gained a bad reputation as a result of many

problems with the company's latest model, the 14/45.

|

Another view of Batham's Bean

lorry. |

The Tipton factory in 1925.

An advert from The Times Trade &

Engineering Supplement, 25th May, 1929.

|

Later Years

A new chapter started in

November 1933 when Hadfields re-launched the

business as Beans Industries. The new company would

produce castings for the motor industry, and soon

became profitable again. In 1937 Beans Industries became a public

company.

During World War 2 the company

produced lorry engines and parts for army trucks. In

1956 the company was taken over by Standard-Triumph to

produce castings for their vehicles, and in 1960 became

part of British Leyland, producing castings for their

lorries and coaches. In 1975 it became known as Beans

Engineering.

In 1988 when the Leyland group was

privatised and broken-up by the Conservative Government,

Beans Engineering was acquired by its management team,

and after the buyout it acquired Reliant. Things went on

much as before until Reliant failed in 1995 and took

Beans into receivership.

The Tipton factory was purchased by

the German engineering group Eisenwerk Bruhl who made a

large investment at the works, where 40,000 tons of

cylinder blocks could be produced each year. The

business became known as Bruhl UK but suffered from

financial problems because the large investment had left

the company in debt. For a second time the management

team purchased the business which then became Ferrotech.

The factory had one of the most modern and efficient

foundries in Europe and became a large supplier of

castings to Rover. Unfortunately Rover went into

administration in 2005, and Ferrotech failed to find a

replacement customer. As a result the story ends in

September 2005 when Ferrotech closed its doors for the last

time.

|

|

Return to

the list

of manufacturers |

|