|

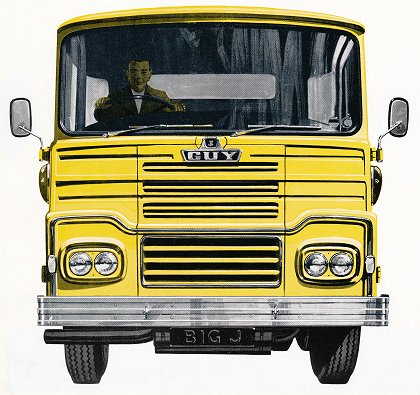

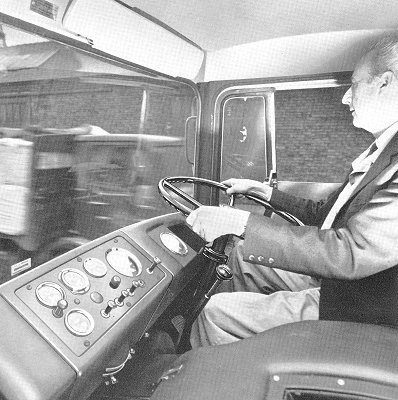

A 'Big J' cab. Courtesy of Brian Shaw. |

The 'Big J' series was available in a range of different forms,

with a choice of engines, gearboxes, and axles to suit the

individual requirements of heavy haulage operators. They were

suitable for both long distance, high mileage work, or for

short-run deliveries, and could handle the toughest off-road

conditions.

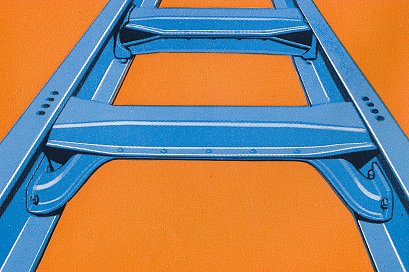

All models in the ‘Big J’ range incorporated an all-bolted

frame assembly, to a standard width of 34 inches, and parallel

throughout its entire length.

Rigid assembly was ensured by the use of pressed channel

section silicon manganese steel members, which were strongly

braced throughout by pressed steel, built-up cross-members. |

| Towing facilities consisted of reinforced holes in both

frame members at the rear, and tapped holes in the bumper

brackets at the front to take screwed towing eyes.

Dual-circuit brakes of the full air-operated, drum type were

fitted to ensure safe and powerful braking under all conditions.

Fail-safe spring-actuated secondary and parking brakes were also

provided to ensure that in the event of a loss of air pressure,

brakes were automatically applied. |

The all-bolted construction of the

chassis. Courtesy of Brian Shaw. |

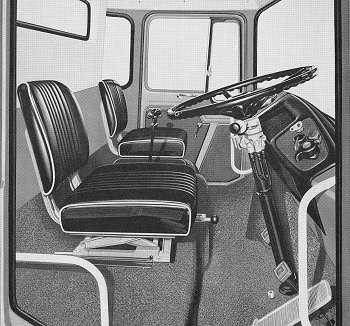

The wide windscreen and conveniently located

instrument panel. Courtesy of Brian Shaw.

|

Courtesy of Brian Shaw. |

5 or 6-speed constant mesh gearboxes were

fitted as standard. Both were identical except that an

additional gear-train, and an extra selector fork were fitted to

the 6-speed box. The 5-speed box had a direct drive top gear,

while the 6-speed box had an overdrive top gear giving higher

road speed under light load conditions. Alternatively a 10-speed

up-split constant mesh gearbox could be fitted.

Provision was made on the right-hand side

for the fitting of a full torque power take-off unit.

Alternative power take-off units were available for left-hand

mountings.

The standard cab for all Big J models was

an all-steel welded assembly with entrance steps ahead of the

front wheels. The assembly consisted of a sub-frame and panels,

which together provided maximum rigidity and durability. Bolt-on

wings and front corner panels were provided for ease of repair,

or replacement. |

|

Emphasis was placed on the roomy interior,

and driver-comfort using high quality trim, and comfortable

seating to enhance the spacious cab design. The wide doors were

carried on robust external hinges, and two large grab-handles

were fitted to ease entry and exit. The entrance steps were

fully enclosed by the door panels, and a large glazing area was

provided for exceptional all-round visibility.

The instruments were neatly positioned in

the fascia panel, with all control switches in easy reach of the

driver. A fully upholstered, shock-absorbing seat was offered as

an optional extra, which allowed adjustment over a wide range of

positions to suit any driver or passenger. |

The interior of the cab. Courtesy of Brian

Shaw. |

|

The following models were available:

|

|

A 'Big J8' sheeted lorry. Courtesy of Brian

Shaw. |

|

A 'Big J6' tipper. Courtesy of Brian Shaw. |

The interior of the cab. Courtesy of Brian Shaw.

A 'Big J6' tanker. Courtesy of Brian Shaw.

A 'Big J4T' and low-loading trailer. Courtesy of Brian

Shaw.

A 'Big J4T' tipper. Courtesy of Brian Shaw.

Another 'Big J4T' tipper. Courtesy of Brian Shaw.

A 'Big J4T' tanker. Courtesy of Brian Shaw.

A 'Big J4' lorry. Courtesy of Brian Shaw.

A 'Big J6' concrete mixer. Courtesy of Brian Shaw.

Courtesy of Brian Shaw.

A 'Big J6' heavy duty lorry. Courtesy of Brian Shaw.

|

Return to

the

previous page |

|