|

Running a

Six-Wheeler on Producer Gas

The results of

an instructive test of a Guy lorry equipped with a

Tulloch-Reading Gas Producer

The article is from The Commercial Motor,

January 29th, 1929. Unfortunately the conclusion is missing. |

|

Nowhere in the world is cheap and efficient

transport by road or across country more important than in our

Colonies and Dominions, where main-line railways are usually few

and the distances between them great. The employment of vehicles

running on petrol is often prohibitive, for the reason that the

fuel is so expensive, and, consequently, bulk produce cannot be

handled at an economical figure.

With the advent of the vehicle running on

producer-gas as fuel, the whole outlook has been altered, and

with satisfactory producers using cheap, native-made charcoal,

or, in some cases, even the raw wood, the running costs per

ton-mile can actually be made lower than is normally obtainable

at home. |

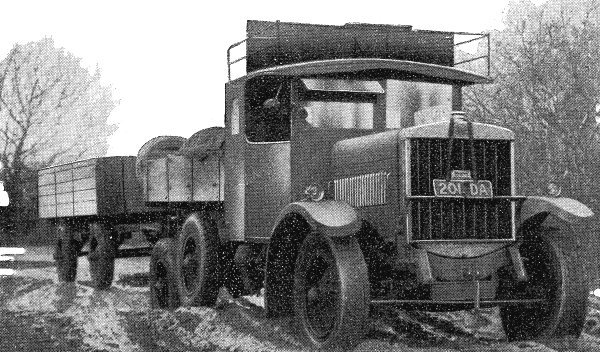

A Guy 6-wheeler running on producer gas,

with a laden trailer over soft tracks.

|

Automatic

Producer Required

The great point is to utilize a producer

which is practically automatic in action; so that the vehicles

can be controlled by men having but little skill. The apparatus

must also provide a clean, dry, dust-free gas which will permit

an engine to be run for long periods without decarbonising being

necessary.

When first produced, the main difficulty

was the long time involved in starting from cold, but in the

latest types this annoying factor has been reduced until it is

almost negligible. Similarly, any stops of more than a few

minutes' duration formerly involved an extended blowing-up of

the fire, but here, again, restarting can be made, even after a

stop of half an hour or more, almost with the same ease as in

the case of the engine running on petrol.

As an example of what can be done with a

modern form of producer, we may refer to some particularly

interesting and instructive trials which were recently carried

out with a Guy rigid six-wheeler employing the Tulloch-Reading

gas-producer.

They were run in England under the aegis of

the Empire Cotton Growing Corporation prior to the shipment of

the vehicle to Nigeria, and an independent authority, whose name

we are not at present permitted to divulge, was invited to deal

with the matter.

Tests were carried out on road and

cross-country tracks, with and without a trailer, the weather

conditions being fine during the running on the road, but wet in

general while cross-country work was being done.

To afford a good idea of the behaviour of

the Guy vehicle, it will first be necessary to give a few

details of it. The engine has six cylinders of 4¼ ins. bore and

5½ ins. stroke, giving an R.A.C. rating of 43.3 hp., the gear

ratios being: Top, 1 to 1; third, 1.722 to 1; second, 2.5 to 1;

first 4 to 1; reverse, 3.86 to 1; there was also an auxiliary

gear of 1.985 to 1, whilst the final-drive ratio to the two

axles was 9.33 to 1. The total weight of the lorry was 8 tons 12

cwt., and that of the trailer with its 2 ton load was 3 tons 12

cwt. 1 qr., the total useful load carried and towed being 5

tons.

Conducting

the Tests

Prior to each test, the fuel hopper, water

tank and petrol tank were filled to a definite level. The road

test comprised 202.1 miles with a trailer and 81.5 miles without

a trailer, the lorry being laden with 3 tons for 40.75 miles,

and for an equal distance with 4 tons.

With the trailer the lorry pulled well, and

on the level the maximum speed of 20 mph. was easily attained.

On hills the drag of the trailer made it necessary soon to

change to a lower gear, but it was noticed that by changing down

to first gear early, a hill could be climbed more rapidly than by

remaining in third and second gears for longer periods. It

should be noted that an engine governor was employed, cutting in

at a maximum of 20 mph., but it appeared rather slow in cutting

out, and before acceleration of the engine could be felt again,

the speed would drop to 15 mph. and sometimes even to 12 mph. |

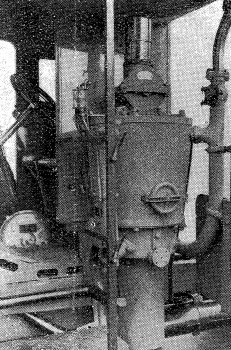

The Tulloch-Reading gas producer, as

fitted to the Guy 6-wheeler. |

Some

Excellent Results

One involuntary stop occurred through an

obstruction in the fuel-feed valve, but to remedy this the whole

valve was removed, cleaned and replaced, and the engine

restarted within 10 minutes. On three occasions, when pulling

hard on a hill, the engine failed through loss of power. This

appeared to have been caused by poor-quality gas, for in the

time taken to restart on petrol and to switch over to gas (two

to three minutes) the fault had rectified itself.

With the trailer, the fuel consumption

proved to be 3.1 lb. per mile; water, 9.6 m.p.g.; petrol, 101

m.p.g. (being used for starting and emergencies only); average

speed, 11.8 mph. Without the trailer, the fuel consumption was

2.8 lb. per mile; water, 23.3 m.p.g.; petrol, nil; average

speed, 12.6 mph.

In the cross-country tests the route comprised rough roads,

sandy and muddy tracks, heather, gorse and grassland. Here the

vehicle ran 419.5 miles, of which 136.8 miles were with a

trailer and 282.7 miles without. The vehicle performed very

well, but with the trailer it was necessary to engage the

emergency low gear to climb a number of the steep hills on the

cross-country course. |

| On favourable ground 20 mph. could be attained, but 6 mph.

was the average over a stretch of heavy sand. In boggy ground

the vehicle became ditched, but when the trailer was unhooked it

was able to extricate itself under its own power, using gas.

A gradient of 1 in 5 was climbed on a grassy slope without the

trailer. On a 1 in 4½ gradient the machine climbed

three-quarters of the way and then stalled through the wheels

becoming locked in loose ruts. After reversing into a more

favourable position on the same gradient, the climb was

completed. When pulling hard in first gear in deep sand the

engine did not overheat, the highest radiator temperature being

149 degrees F., with the atmospheric temperature at 57 degrees.

Three stops occurred on hills through loss

of power, but restarting on petrol and switching over to gas

solved the problem. |

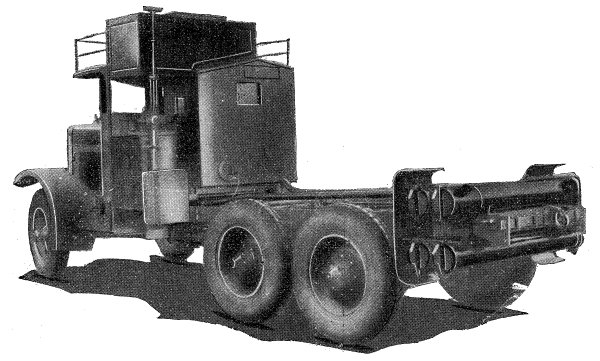

A rear view showing the producer, hopper, and

scrubbers.

|

The Drawbar-pull Tests

In a drawbar-pull test, the lorry, carrying

3 tons of iron ballast and fully equipped, towed a tractor with

a weight of 7 tons 18 cwt., using the Watson dynamometer. On wet

tar-macadam the tractor, having both brakes on, and the vehicle

being in the low-reduction gear, a pull of 6,500 lb. was

registered. The vehicle, although running on gas, did not stall,

but pulled the tractor along the road with its wheels locked. It

is obvious that the actual drawbar pull could have been much

greater than that registered.

In the cross-country tests the results were

as follows: with trailer, fuel, 4.6 lb. per mile; water, 17.6

m.p.g.; petrol, 54.7 m.p.g.; average speed, 7.3 mph. Without

trailer, fuel, 4.4 lb. per mile; water 13.1 m.p.g.; petrol, 40.1

m.p.g.; average speed, 11.4 mph.

No difficulty was experienced in

maintenance. Replenishment of the hopper and the water tank, and

cleaning the cyclone dust extractor and scrubber, drawing the

fire and emptying the ashpan were carried out daily, but proved

to be quite simple. Lighting the fire, producing the first

supply of gas, starting on petrol and switching over to gas

averaged 10 minutes.

The fuel delivered with the vehicle gave

better results than that obtained in London; the latter made it

necessary to empty the cyclone and clean two scrubbers after 50

miles. With good quality charcoal, pure ash could be obtained

from the cyclone, and there was very little fouling of the

scrubbers; cleaning, in this case, would not be necessary until

after 100 miles. Good charcoal obviously gives the best results,

but dusty charcoal can be used with good results, except for the

extra cleaning which is then necessary.

Grade 3 petrol was used for starting the

engine and for driving the vehicle in and out of the garage when

the fire in the producer was out. After 539 miles running, the

sparking plugs were examined, but cleaning was not necessary.

The cylinder heads, induction pipes, exhaust pipes and valves

were stripped down for inspection. The total weight of deposit

on the cylinder heads was 168 grains, whilst the induction pipes

and exhaust pipes were found to be quite clean.

The summary of the results obtained is as

follows: Total mileage, 703.1; total ton-miles, 2,827.85;

charcoal used, 1 ton 4 cwt. 2 qrs.; petrol used, 10 gallons;

average charcoal consumed per mile, 3.9 lb.; average charcoal

consumed per ton-mile, .97 lb.; average cost of charcoal per

ton-mile at £1.10s. per ton, .156d.; saving in total running

costs, including all petrol used, £2.9s. per 100 miles with

petrol at 2s.6d. per gallon; £2.19s. with petrol at 3s. per

gallon; £3.10s. with petrol at 3s.6d. per gallon, and £4 with

petrol at 4s. per gallon.

The trials were carried out entirely by the

observer and driver appointed by the authority conducting them,

after some demonstration runs and instruction during three days,

and without any further help in anyway from the makers.

The air and steam preheating arrangements

were adjusted for the temperature and atmospheric conditions in

places like Nigeria; consequently, the full amount of water

could not be used. Only .2lb. of water per pound of charcoal was

supplied, instead of approximately .5 lb., the result being that

the gas was of a lower calorific value than it would be in

Nigeria. Under commercial conditions the amount of petrol used

for the mileage run could be reduced by more than 50 percent.

The cylinder heads examined at the completion had been untouched

for 1,500 miles. |

|

Return to the

previous page |

|