| Guy Motors was founded by Sydney Slater

Guy, a clever and ambitious young man, who had the determination

to succeed. He was born in 1885, and grew up in King’s Heath,

Birmingham. At the age of 16 he joined the Bellis and Morcom

steam engineering Company, at Ladywood, Birmingham, after being

offered a job in the factory. His employers were clearly

delighted with their new member of staff because they soon

offered him an apprenticeship. He attended evening classes at

the local technical school, which stood him in good stead for

the future. In 1906 he obtained the post of service manager for Humber at Coventry. |

Sydney Guy.

|

In June 1909 he joined the up and coming

Sunbeam Motor Car Company Limited, in Upper Villiers Street,

Wolverhampton, as works manager. The company soon became well

known thanks to Sunbeam’s flamboyant chief engineer, Louis

Coatalen, who had joined Sunbeam in February of that year.

During Sydney’s first 4 years at Sunbeam,

production greatly increased, and profits soared, so he

naturally wanted some reward for his efforts. At the time he had

an annual salary of £250, and the use of a company car. In 1913

he asked the directors for an increase in salary, which was

refused. This possibly led to him leaving Sunbeam the following

year.

| |

|

| Read about Sydney

Slater Guy |

|

| |

|

Sydney Guy had clearly been thinking about,

and planning his own manufacturing business whilst still at Sunbeam. The design

for a 30 cwt. lorry was produced in a small drawing

office in Wolverhampton, in late 1913, and plans were made for

the factory which would be built the following year, in Park Lane, Fallings Park,

Wolverhampton. Guy Motors Limited was registered on the same day

that he left Sunbeam, Saturday, 30th May, 1914, and building

work on the new Guy factory rapidly got underway.

At the time, a great deal of new industrial

development was taking place in the Fallings Park area.

Previously factories had been sited closer to the town centre

and to the canal and railway network. But by this time there was

less reliance on these modes of transport, particularly in the

motor industry, and in any event, no space would have been

available nearer the centre, especially for new factories which

required greater floor space. Guy’s new factory was in

production by September 1914, nearly one month after the

outbreak of the First World War. |

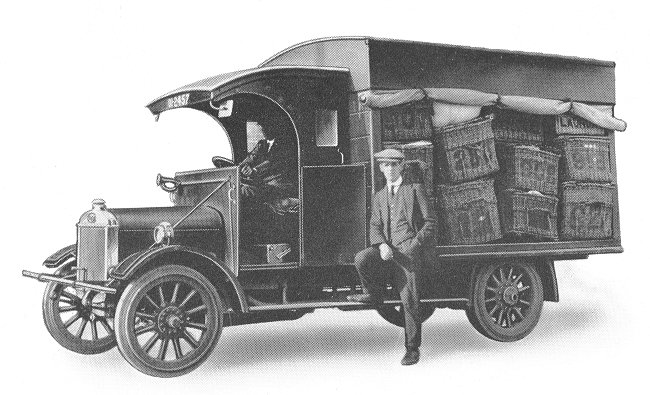

A 30 cwt. Guy lorry.

|

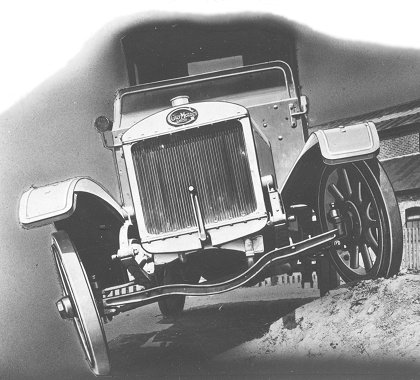

The horizontal sub-frame can just be seen

below the radiator. |

The company’s first product, a 30 cwt.

lorry, included several new and innovative design features. It

was powered by a White and Poppe 4-cylinder, side-valve petrol

engine, with a cone clutch and gearbox, mounted on a sub-frame

suspended at 3 points.

This arrangement prevented any distortion of the chassis,

when traversing uneven ground, being transmitted to the engine

or gearbox.

The gearbox had a direct drive in 3rd gear for use when fully

laden, and an indirect 4th gear for use when travelling ‘light’,

a facility that later became known as ‘overdrive’.

Another innovation was a governor, which only acted on 4th

gear to limit the top speed to 30 mph. |

|

An advert from December 1917. |

|

An advert from July 1918. |

| The lorry had a lightweight pressed steel chassis, instead

of the conventional heavy rolled steel chassis that was used by

many manufacturers at the time. A 30 cwt. running chassis was

priced at £435.

There were also 50 cwt. and 2 ton versions. Guy’s second product, a passenger carrying

vehicle, built on the same 30 cwt. chassis soon appeared. The 14-seater post bus, with a mail compartment, was built for use in

Scotland between Achnasheen railway station, east of Kinlochewe,

and Aultbea, on the west coast, north of Loch Maree. |

The 14-seater post bus.

| In 1915 the factory came under the control of the Ministry

of Munitions, and concentrated on war work.

30 cwt.lorries continued in production and were supplied to

the Russian army.

Other products included engines for tanks, aero engines, and

depth charge firing mechanisms.

Guy became the largest manufacturer of depth charge firing

mechanisms in the country.

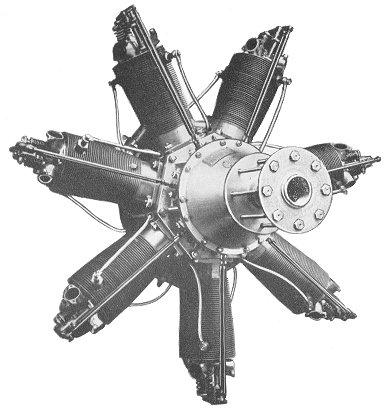

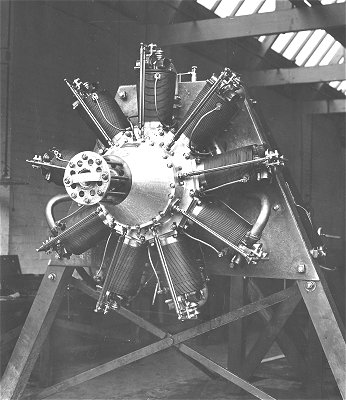

In 1917 the company was asked to produce A.B.C. ‘Wasp’ 7

cylinder, air cooled, radial aero engines. |

The A.B.C. ‘Wasp’ 7 cylinder, air cooled,

radial aero engine. |

|

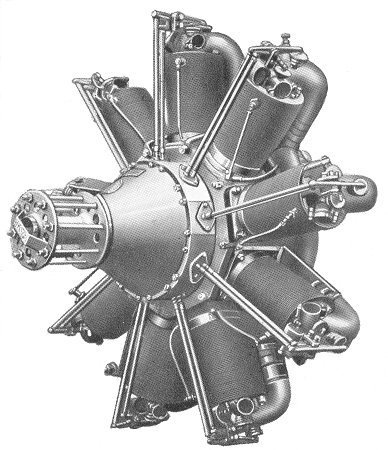

The A.B.C. ‘Dragonfly’ radial aero engine. |

The

project was clearly a success because during the following year

Guy built the prototype A.B.C. ‘Dragonfly’ 9 cylinder, 350 hp.

radial aero engine.

The prototype was built and tested in just

24 days, following the receipt of the order.

The government was

delighted, and Guy received the following telegram from Sir

William Weir, Secretary of State for Air:

Reference to your telegram of yesterday

regarding dragonfly engine. I heartily congratulate you on your

magnificent performance, the result of which it is hoped will

mark a new milestone in progress.

|

| Sir William Weir's telegram. |

|

|

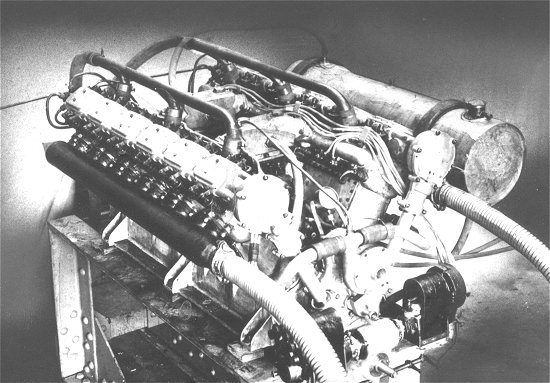

A 'Dragonfly' engine mounted on a test

rig at the works. Presumably the

original prototype. |

|

A group of officials examining the

prototype 'Dragonfly' outside the Guy factory. |

|

Another view of an A.B.C. 'Dragonfly'

350 hp. radial aero engine. |

Guy also designed and produced a

12-cylinder aero engine.

|

Thanks to the many ministry orders, Guy

prospered during the war. The company became an established

name, and the factory greatly increased in size. By the end of

the war it was well equipped with some of the latest plant and

machinery. |

|

|

|

|

Return to the

beginning |

|

Proceed to

The

Early Inter-War Years |

|