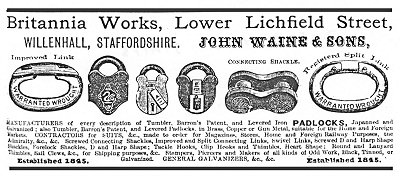

JOHN WAINE AND SONS (WILLENHALL) LTD. BRITANNIA

WORKS, LOWER LICHFIELD STREET, WILLENHALL

|

Founded in 1845. An advert in the Directory

of Staffordshire 1880 lists them as manufacturers of every

description of tumbler, barron’s patent and levered iron

padlocks, also in brass. |

|

They were also manufacturers of screw connecting

shackles and split connecting links, swivel links etc for shipping

purposes; and they were also general galvanisers.

In 1931 they were selling the Britannia Cylinder Night Latch, which

was made for them by George Spencer Limited.

Run by two brothers (names?). Existing in 1974. Nothing

else known.

|

An advert from 1954. |

An advert from 1920.

|

|

| View pages from some old John

Waine & Sons catalogues |

|

| |

|

A John Waine & Sons padlock.

|

Courtesy of Trevor Dowson.

Courtesy of Trevor Dowson. |

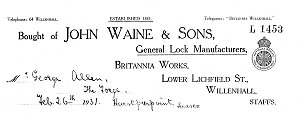

The image (left) is of a letterhead dated 1931 but

the telephone number, "64 Willenhall" suggest an earlier

printing. |

|

The advert (left) is from the Ironmongers Guide, 1950, trade

marks section.

Presumably the head is that of Britannia

and was being used as their trade mark.

|

|

|

A letterhead from the late 1930s. |

JOSEPH WAINE & CO. LTD. IMPERIAL WORKS, WOOD STREET,

WILLENHALL

Joseph Waine & Co. Ltd, were general lock, latch & bolt

makers, and brass and iron founders at Imperial Works, Wood

Street, Willenhall. Joseph had three sons, John Vincent Waine,

G. A. Waine and Horace Theo Waine.

|

John Vincent Waine, and his brother G. A. Waine, started the

Vulcan Manufacturing Company at Blackheath, Birmingham, in about

1910. The company manufactured Heel Tips, Toe Plates and had the

most up to date machinery in the world. The factory turned out

288,000 pairs of heels per week, under their Vulcan brand name. The company specialised in a number of products including No. 0

and 1 York heels, 21B heels, mule & horse shoes for the Indian,

Turkish, African and South American markets, and japanned and

galvanised door bolts. A large number of other products were

produced including the following:

Brass, chromium-plated and special finishes, stainless steel,

garage bolts, cabinet bolts, shelf brackets, aluminium door and

gate latches, casement stays and fasteners, hasps and staples,

hinges, brass and steel gate and tee, gutter brackets, swivel

ties, tinned angle brackets, rim, dead and mortice locks,

latches, padlocks, stamped brassware and household soldering

sets. |

|

Courtesy of Trevor Dowson. |

The factory covered over an acre. Extensive trade was done with

the War Office, the Army and in various parts of Europe. Horace

T. Waine was also involved in the business, and due to his

international travels the products were also sold in Japan,

Burma and Egypt. The company also had an establishment in the

Potteries.

In 1913 the Directors decided to move the three factories to one

site to improve the company's efficiency. In June a large

disused works was purchased in Colliery Road, Wolverhampton and

the three factories were combined under one roof, and called the

New Griffin Works.

|

Theo Waine on a lock selling trip to

India. |

In 1928, Theo Waine and his brother Mr. G. A.Waine,

took over the Wearwell Cycle Company Limited from the liquidators of

the Wulfruna Engineering Company Limited.

Their sons, H. V. Waine and T. A. Waine were issued with one

ordinary share each, and were appointed directors at the first

shareholders meeting, which took place at the New Griffin Works.

The new company was registered as the Wearwell Cycle Company (1928)

Limited.Lock manufacture continued for some time, but

eventually the firm concentrated on the production of bicycles

and motorcycles. |

SAMUEL WAKELAM AND CO, WATERLOO PLACE,

STRINGERS LANE, WILLENHALL

Trunk, cash box and cabinet lock makers. Existing

in 1914 and 1953 but not 1970. Nothing else known.

WALSALL LOCKS AND CARTGEAR LTD, NEALE STREET,

WALSALL

|

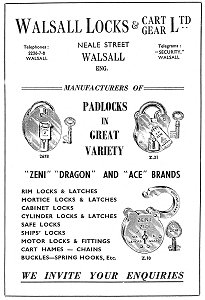

An advert from 1958. |

The company was set up in 1873 as a result of an

industrial dispute between the workers and their employers. A

demand for higher wages resulted in a lock-out with no wages earned at

all. A benefit fund was collected from donations so that the out

of work people might get some assistance while the dispute continued. £150 was raised and distributed. Mr. G. Harrison reported to the

Walsall Trades council that the £150 paid out seemed futile, for the men

were still out of work and still not earning.

Why was not the

money raised used to set the workers up in their own workshops and

become self employed? And so Walsall Lock and Cart Gear was

formed.

Known as the Walsall Padlock Society in 1879, it adopted

many titles over the years: "The Walsall Lock and Keysmiths

Society Ltd"; later "The Co-operative Walsall padlock Company."; in 1887 the company was trading in the name of Walsall Industrial

Co-operative Lock and Hardware Manufacturing Society Limited".

|

| In 1888 the members faced the responsibility of using so

much co-operative and trade language in their business and, in

the interest of economy of speech and writing and ink, adopted

the name of "Co-operative Padlock Society Limited." They later became Walsall Lock and Cart Gear as

their range of products widened. (Further information "The History of

Walsall Locks and Cartgear Ltd 1873-1923" by R. Halstead )

|

|

This sign board is in the

Locksmith's House at Willenhall. |

|

|

This notice, from the

Ironmonger Guide 1950 trade marks section, shows a dragon trade

mark. |

| The Dreadnought padlock, patented 1895, when the

company was going under the name Walsall Locks & Cart Gear Ltd..

The key on this remarkable lock fitted over the bars on the

front of the lock and was then moved sideways to open the lock.

Courtesy of the Locksmith's House. |

|

|

A 1929 letterhead. Courtesy

of

Trevor Dowson. |

They built premises in Neale Street, Walsall and later

expanded to having branches at Walsall Road, Willenhall (used until the

1960s) and Newhall Street, Willenhall. (In 1936 they were at

Newhall Street, only closed earlier).

|

|

In the 1920s they expanded their range to

include a cylinder pin tumbler night latch, which was sold under

the ZENI brand name. They also used the ACE brand.

|

|

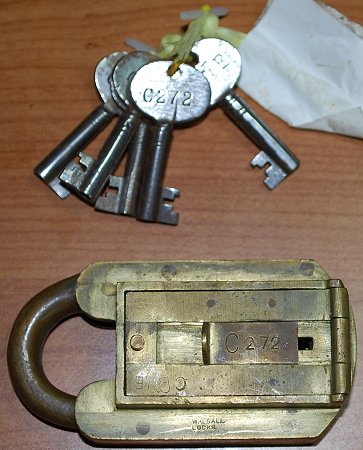

A Walsall Locks & Cart Gear

padlock. Courtesy of Nigel. |

| In 1975 they changed their name to Walsall Locks

Ltd, as they were then only making a few items for the

equestrian trade. They went into liquidation in 1985, when

employing 85 people. A dividend of 46 pence in the pound

was paid to creditors. The lock making part was taken over

by Len Bates (who was the "B" in ABT Hardware) and Paul Preece,

who formed Walsall Lock and Hardware Ltd and moved into new

premises at Leamore Close, Leamore Industrial Estate, Walsall,

on the 10 February 1986. They continued to make a small

part of the original range of padlocks.

On the 1st April 1997 they changed the name to

Walsall Locks Limited. This was felt to describe the

activities of the company and reflect the identity that they had

built up within the industry. They manufactured ZENI and

ACE padlocks, while importing mortice and safe locks for resale.

(LMNL No 28)

|

An advert from 1955. Courtesy of Trevor Dowson. |

|

A Walsall Locks Limited brass padlock.

Courtesy of Nigel. |

A close-up view of the above padlock. Courtesy

of Nigel.

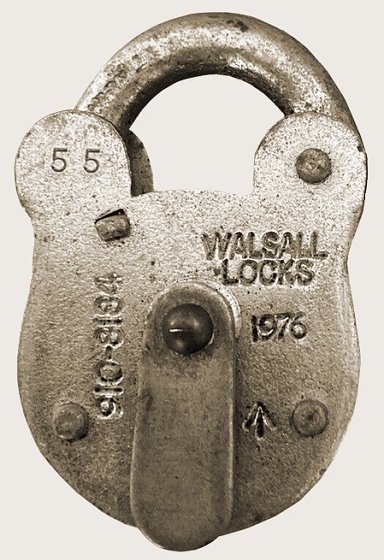

A Walsall Locks padlock from 1949.

A Walsall Locks padlock from 1976.

A Walsall Locks & Cart Gear

padlock.

A Walsall Locks & Cart Gear

padlock.

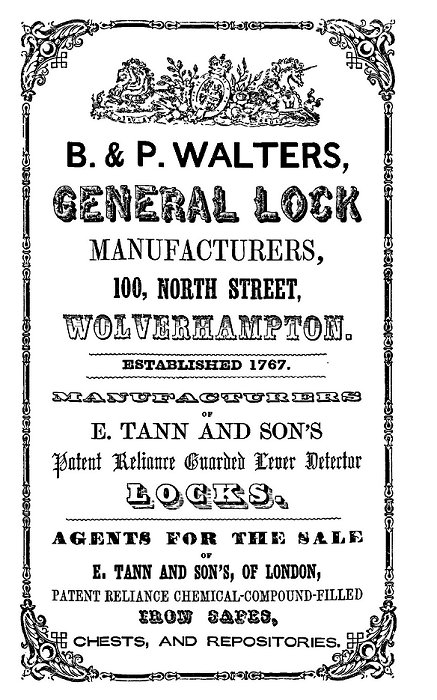

B. & P. WALTERS, 100 NORTH STREET, WOLVERHAMPTON. Also

BENJAMIN WALTERS AND CO. LTD. 24 NORTH STREET, WOLVERHAMPTON.

|

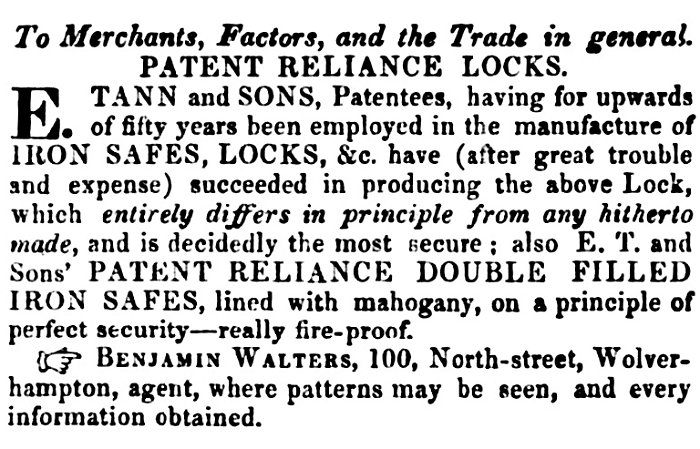

An advert from 1851.

|

|

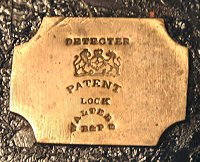

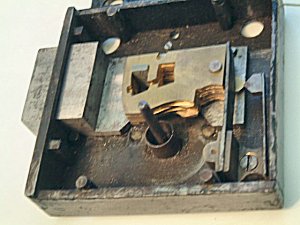

Tony Beck has kindly provided the following photos of a

lock marked "B & P Walters".

|

A safe lock with "detecter", from the Victorian

period, by B & P Walters (from Tony Beck's collection". |

|

A close-up view of the brass plate from the safe lock

above. |

|

|

The interior of the safe lock above. |

I must thank Jo Barreiro for the following information.

She has researched both companies.

A long list of local tradesmen in the Wolverhampton

Chronicle and Staffordshire Advertiser, published on Wednesday the 12th

June, 1844 includes Benjamin Walters, lock manufacturer.

There is a mention of a new patent taken out by Benjamin Walters, of

Wolverhampton, for improvements in spindles for locks and latches, and

the means of adjusting knobs to suit any thickness of door. Dated July

3rd, 1854. It is listed in the Birmingham Journal, on Saturday 6th

January, 1855.

In 1856, Benjamin Walters, 100 North Street, is listed as agent for E.

Tann & Sons. The address confirms that the initial 'B' in B & P Walters,

is Benjamin.

From the Wolverhampton Chronicle and

Staffordshire Advertiser, Wednesday the 1st January, 1845.

Courtesy of Jo Barreiro. |

In 1863 there were two

articles about an assault on Benjamin Walters, lock manufacturer, of

North Street, by his brother Philip Walters, former auctioneer. This

suggests that the initial 'P' in B & P Walters, could be Philip. The

articles are in the Staffordshire Advertiser, Saturday 27th June, 1863

and the Birmingham Daily Gazette, Tuesday 23rd June, 1863.

The following article from 1862 records how Benjamin was

shot in a shooting accident. The article also states that his home was

at Albrighton and that he was a sergeant in Lord Dartmouth's Patshull

Company.

|

Unfortunate Accident at a Rifle

Match

A match has

taken place at Earl Dartmouth’s

Range between North and South

Staffordshire. The North scored a

total of 368, and the South marked

920. After dinner the competitors

assembled at the 600 yards’ range

for the purpose of shooting seven

shots each at a distance, when a

most lamentable accident occurred. A

number of men, we believe on both

sides, snapped off caps, some of

them taking aim at the targets, with

a view, probably, to see if they

were steady.

At this time

there were half a dozen of the

markers at the targets, re-painting

them ready for firing, and one of

these, Mr. Benjamin Walters,

lock-manufacturer, of North Street,

Wolverhampton, who resides at

Albrighton, and is a sergeant in

Lord Dartmouth’s Patshull Company,

was shot with a bullet, which

striking him on the left side,

passed through the flesh near the

ribs, and through the flesh of the

arm, striking the centre of the

target. This shot was fired by

Sergeant Bowker, of the Trysull

Company.

At the target

with Mr. Walters was a gentleman who

at once stripped Mr. Walters and

adopted means to stop the bleeding,

which was considerable. Great

consternation was naturally

occasioned amongst the large number

of spectators then assembled, and

two horsemen at once galloped off to

the butt, their turn being awaited

with intense anxiety, as beyond

seeing the unfortunate gentleman

fall and bearing a scream, the

result of the accident was unknown.

It was most

satisfactory to find that he was

living, and Mr. Hopkins, a medical

man, and Mr. Beck, who was

apprenticed to a surgeon, were soon

in attendance on him, and he was

conveyed in a carriage, first to

Patshull Hall, and afterwards to his

residence.

We are happy to know that he passed

a good night, and it is hoped that

he is now in a fair way of recovery.

Of course, had the shot struck about

an inch more to the right, it would,

in all probability, have at once

been fatal. A small artery in the

arm was injured and the main artery

just missed. The affair was purely

accidental. |

|

|

|

From the

Loughborough Monitor, Thursday the 25th September, 1862.

Courtesy of Jo Barreiro. |

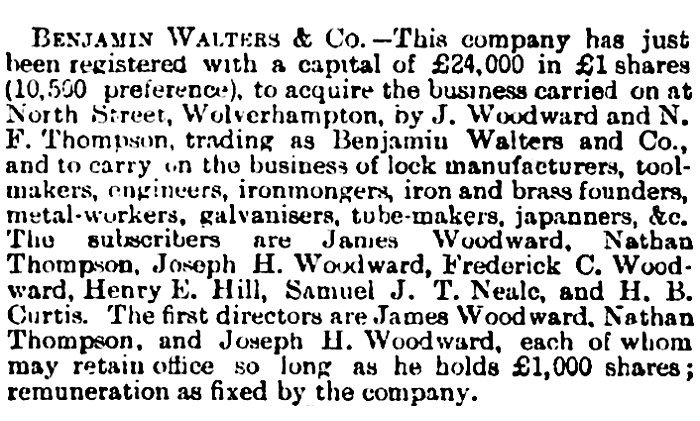

The following newspaper article states that in 1900 the

company was sold along with the trading name, to J. Woodward and N. F.

Thompson, trading as Benjamin Walters & Co., North Street,

Wolverhampton.

|

From the Birmingham Daily Post, Tuesday

the 3rd July, 1900. Courtesy of Jo Barreiro. |

The firm was listed as general lock makers, of all kinds of rim and mortice

locks and latches, combination and night latches, and every description of

brass and iron cabinet locks. Also Bales & Walters improved patent

locks and latches. They made their own cabinet locks and Bales latches

but acted as wholesale factors for many other types.

They are listed as being at 154 North Street in 1956 and by

1960 were situated upstairs at 24 North Street, opposite the Molineux Hotel. The business closed when the premises were required for the

building of the Wolverhampton ring road.

W.B.S. SAFE LOCKS LTD. HART ROAD, WEDNESFIELD

|

|

W.B.S. Safe Locks was founded by

William Bernard Sidbotham during 1946.

He rented a small workshop in

Vale Place, Merridale Street, Wolverhampton. The

rent was eight shillings per week (40p in today's currency). At this

time he had one employee and went on to employ another three later,

including his son.

|

His first order was for a trial for a

small quantity of locks from the safe makers, Samuel Withers & Co. Ltd.

(q.v.) for whom he became the main supplier of locks for their

safes.

During the early 1950s he bought

premises at 38 Hart Road, Wednesfield, nr. Wolverhampton where he formed

a limited company and became W.B.S. Safe Locks Ltd.

After being demobbed from the army in

January 1948 his son, K.W. Sidbotham, went to learn the art of making

locks, the old way by hand, under his father’s teaching. They

specialised in the making of locks for safes and many other types of

securities, of which bank work was their speciality.

K.W. Sidbotham ran the firm when his

father left and under him the firm expanded considerably. In

particular they went on to repair and install safes and strong room

doors, working for banks, police forces, prisons and other places using

safes and high security doors. During 1960 the firm became involved in

the making of rackbolt locks, which turned out to be a vital string to

his bow when Bob Sidbotham moved to the Guild Cottage, Radmore Lane,

Newport Salop, from where he ran his business and worked his trade for

twenty five years. The rackbolt lock was made for a London company of

locksmiths for a refurbishment programme, service work included, for one

of the leading High Street banks.

This order lasted about thirty years

after which Mr. K.W. Sidbotham retired from lock making, due to poor

health. His cousin, Mr. K. Rooker, of Regent Safe & Cabinet Locks,

Willenhall, (q.v.) helped out and they worked together very well.

We are obliged to Mr. K. W. Sidbotham for

help with the above entry. A book by him gives further details of the

company as well as a picture of the working conditions and practices of a

locksmith in the second half of the twentieth century: K. W. "Bob"

Sidbotham, Life and Tales of a Locksmith, History into Print, 2005, £9.95.

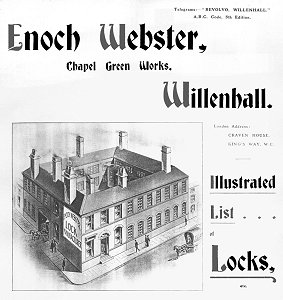

ENOCH WEBSTER, CHAPEL GREEN WORKS, WILLENHALL

|

Manufacturers of mortice and rim locks.

Established in the second half of the 1800s.

In 1881 Enoch

Webster, aged 41, lived at 18 Cannon Street and is listed as a

lock manufacturer, employing 1 man and 4 boys.

The inside

of all the parts in their locks were marked with a logo: E.W.W.

in a triangle |

WEISER (UK) LTD. NORTH WEST INDUSTRIAL ESTATE, PETERLEE,

COUNTY DURHAM

The UK branch of a USA company who set up in Peterlee to

manufacture their range of pin tumbler locks in the UK. They also

had a branch in Sint-Niklaas, Belgium. Closed in the early 1990s

when demand decreased and production was transferred to Belgium.

WEST ALLOY DIECASTINGS LTD. GARTH ROAD, MORDEN,

SURREY

West Alloy Diecastings is a privately owned company founded in 1952.

The company began as a trade shop, producing zinc diecastings, and

fairly quickly moved into the design and manufacture of locks, enjoying

considerable success with a main lock for caravans. Further

versions developed and the success of the design can be measured by the

fact that three of these assemblies are still in current production.

By the 1960s West Alloy was also manufacturing hinges, drawer pulls,

catches and folding table legs. When fuel economy became a major

issue in the seventies, West Alloy responded by introducing a design of

lock predominately manufactured in plastic. Retaining one or two

zinc castings, the change to plastic reduced the weight by 60 to 70%.

It was this change that opened the door to other market opportunities.

In the early eighties West Alloy identified a market opportunity and

set about designing a purpose built lock for tractor cabs, based on

locking round a stud rather than on the traditional slam type lock used

by the caravan industry, the major market for the company’s locks at

that time. The resulting design was a much stronger interior lock,

produced predominately from steel pressings - a considerable departure

from the original core business of zinc diecasting. Introduced in

1984 the tractor cab lock was designed to operate with an existing

diecast exterior and incorporated a diecast operating lever to enable

the door to be opened from the inside. At the time it wasn’t fully

appreciated how flexible and successful this design would become and

that it would lead to several new generations of products.

West Alloy currently produce a wide range of parts for construction

equipment and tractor cabs, caravans, garage doors and office furniture.

The majority of products are West Alloy’s own design and are

manufactured at the company’s two factories at Morden and Sutton,

Surrey. The company employs a work force of ninety and is equipped

with all the necessary equipment for producing diecastings and plastic

mouldings. Approximately 65% of the company’s products are for the

U.K. market, the balance being exported to Europe, Australia, South

Africa, Japan and the U.S.A.

In 1998 Mr B Sugden was the Managing Director. The firm had 86

employees. Their turnover was £4 million.

WEST END LOCK CO. NEW ROAD, WILLENHALL

|

Makers of rim and dead locks, brass and iron

padlocks, and gas meter locks. In existence in 1921 and

1974 but not 1914. Closed in 1970s.

|

WESTON BODY HARDWARE LTD, 27 WALKER ROAD, REDDITCH

Manufacturers of die cast lock cylinder barrels, budget locks,

compartment locks. Set up in the 1970s to manufacture the

"Wilmot Breedon" range of locks and latches when Josiah Parkes decided

they did not wish to continue to produce the range they had made for

Wilmot Breeden for so many years.

|

|

| Return to

Locks and Safes |

Return to

the list of makers |

|