7. The Products

Many of James Gibbons many products can be

seen elsewhere on this web site. The company made millions of

locks and other items of door furniture and architectural wares.

Eve what might seem like standard products were made to a very high

standard.

To look at such a mundane candlestick made by James Gibbons, will

suggest quality and longevity. not cast as one piece to just light a

room, but made like an article of character to be looked at as well

as the flame that surmounted it.

Made from eight parts of individual castings, each having to

be finished and bronzed to perfection to produce a unit that was of

quality and desirability.

It is no wonder that Sir Christopher Wren was a customer followed by

other nationally famed architects.

But the real skills of the workmen were often called into play for

special, one off items. A lot of these were the responsibility

pf the Art Metal Department.

|

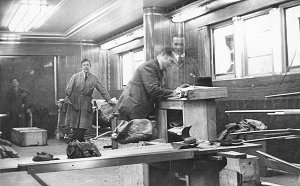

The Art Metal Department

in a photograph of 1933. The names appearing on the

photo are: Elkin, Edwards, Hitchman, Bayliss, Jenks,

Critchlow, Williams, Tittensor, Heyweed, Connelly, Knock,

Edwards, Reynolds, Handley, Hallett, Shinton, Hales, Tarver,

Ireland, Hall, Hartland, Sidebottom, Beddows, Richards,

Wharton, Stan ?, Fox, Reeves. |

| The Art Metal Department

in their shop, also photographed in 1933. |

|

|

A less posed (and more

relaxed!) snap taken in the Art Metal Department. |

|

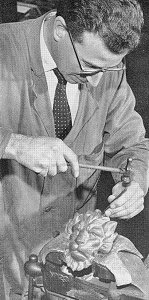

On the left Graham Chalk

chases a bronze, lion head door knocker. (Chasing

brings out the details from a casting and provides a quality

finish).

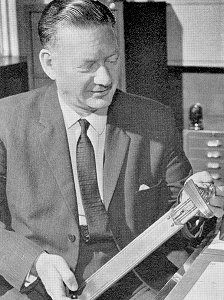

On the right Norman Claxton (who

was with Gibbons for more than forty years) holds one of the

bronze door handles made for the rebuilding of the House of

Commons. |

|

Here are just a few more examples of Gibbons products from photos in

my collection. They range from the artistic one offs to the

more mundane items and even the macabre..

|

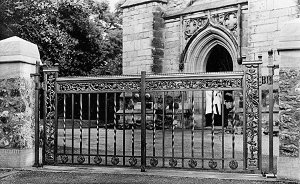

Canopy for the bishop's

throne and railings made for, I believe, Cardiff Cathedral. |

|

Ornamental church gates. |

|

|

This is Mr. Mason of

Fortnum and Masons. In the 1960s twelve Gibbons

craftsmen worked for eighteen months on the decorative

metalwork for the famous carillon clock on Fortnum and

Masons store in Piccadily, London. |

| Crown House, Birch

Street, Wolverhampton, for which Gibbons provided all the

window frames. |

|

|

Lockers for changing

rooms. Gibbons invented the lock which requires a coin

to be inserted before the key is removed and the locker

closed and which returns the coin when the key is reinserted

and the locker opened. |

| George Millard (who

worked for Gibbons for over thirty years) making final

adjustments to a motorised mortuary rack. The TI

magazine, in 1968, called this a "very steady selling line".

They also mentioned "British Rails new luggage racks in

stainless steel, firemen's lockers, and poison drug cabinets

for hospitals fitted with special locks and opening

devices". |

|

|

Workers from the

factory often had to travel to see to the installation of

their products. |

| Here a group of workers

were snapped on board the Queen Mary, just before she sailed

on her maiden voyage. They had been carrying out work

on the fittings. |

|

Nefertiti and Akhenaten

Somewhere, someone has a unique and quite valuable artefact without

knowing its history. This is a perfect

replica of the head of Nefertiti, the wife of Pharoah Akhenhaten.

This almost unbelievable story in Gibbons history of course

will be ridiculed by some who would not believe that two of the mort

precious artifacts in the history of the world should be lodged in a

safe in the back streets of Wolverhampton.

Both the heads of Akhenhaten and his Queen Nefertiti were in

the factory of James Gibbons in the late 1920s shortly after Howard

Carter had found the tomb of

Tutankhamen in 1922.

These heads had been loaned to Britain by the Staatliche Museum,

Berlin, before Hitler came to power or shortly after, as there is no

doubt that he would not have given permission for such objects to

leave Germany.

Of all the workshops of

Britain, Gibbons were given the job of trying to capture the process

of casting used in Egypt at the time of the pyramids.

They had to produce an exact copy of the mask or face of

Akhenaten and to do this they had to use both heads

to get it right:

only a man of the highest skill in casting would be allowed to carry

out this task and Gibbons had such

a man, Fred Wakeman.

Such was the success of Fred Wakeman and the dressers and finishers

that Mr James Gibbons had a book of appreciation printed and

presented to the caster.

That book exists in the Wolverhampton area as a family heirloom.

A condition of the exercise was that all testing products and

practice heads should be returned to the furnace to prevent

proliferation of such wonderful objects.

|

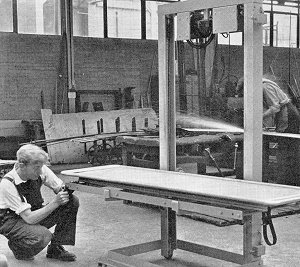

A photograph of the Art

Metal Department at work, taken some time after World War

Two. But what are the two items at the far end of the

workbench? |

| This enlargement from

the photograph above shows the two items at the far end of

the workbench. That is Nefertiti on the right and

Akhenaten (without a crown) on the left. |

|

It is now obvious that this was not strictly adhered to as right up

to the retirement of Mr Paul Gibbons, and afterwards, a head of

Nefertiti stood on the board room mantleshelf.

|

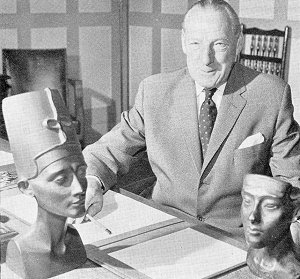

On his retirement in

1968 this photograph of Mr. Paul Gibbons appeared in the TI

magazine. There is no doubt about what he has chosen

to be photographed with. |

Later it was seen to be gathering dust in several departments until

it suddenly disappeared.

Someone now has it, who may know it is Nefertiti but does not

know its worth as an exact copy that should not be in existence.

And Akhenaten himself must be around somewhere.

|