|

Bradley & Co. Ltd

(Beldray)

Mount Pleasant, Bilston |

|

3. Art Metalware

|

Fruit bowl in brass, with acanthus band.

photo courtesy of Vin Callcut.

Other photos on this page by Jaap Arriens and Frank Sharman.

|

A report on the founder of the company, Walter S.

Bradley, which appeared in the Birmingham Gazette on 16th

September 1908, suggests that the firm started making art metalware in

or about 1903. This would be quite a late date to enter this

field, many of the other makers in the Wolverhampton area having started

around the 1870s. But it seems to be a firm date.

|

However the earliest known company catalogue of

holloware lists no les than nine different copper kettles,

mostly of a plain design. The catalogue also adverts

to a separate art metalware catalogue, suggesting that the

plain copper kettles, at least, were seen as part of their

normal stock and also suggesting that the company made

copper kettles long before 1903. |

| Such documents on the history of Beldray as there are

give no specific reason given for the company entering into

this field. The art metalwares were introduced about

the time that the founder's eldest son, Hermon Bradley,

joined the firm and it was originally thought that the

introduction of the new line may have been something to do

with him. But it is now clear that the most important

factor was Harry Doubleday's joining the firm in 1902 or

thereabouts as the works manager. |

| He had previously

worked with Sankey's, in production, and was engaged by

Walter Bradley specifically to modernise the factory and to

help lead expansion. Doubleday would have been well

acquainted with Sankey's successful brass and copperwares

and well aware that, for a company which had been working in

sheet metal for many years, there would be little or no

technical problem in adopting new materials and that the new

machinery he was installing could be used for the purpose. |

|

|

The art metalware products were made of brass or copper,

with the occasional use of wrought iron for stands and such.

The wrought iron parts were probably made by Bradley's

themselves as there is clear evidence of blacksmithing on

their premises. Copper was also used as a substrate

for other finishes, such as a bronzed finish and later,

after the introduction of chrome plating to the UK in 1925,

for chrome plate. Before that a silvery finish had

been obtained by the use of a chemical applied in the same

way as the bronze finish. Brassware was also

finished in a matt gold. Many of the variations of

design shown in the catalogues and surviving pieces were

obtained by making different combinations of finishes and

body shapes and decorative bands. |

| Whilst the company made almost everything in the art

metalware line there are far fewer trays than one might

expect. This may be because trays were an established

speciality of Joseph Sankey & Sons who were just down the

road. But there is a much greater variety of vases and

bowls than Sankeys, or any of the Wolverhampton makers,

produced. Those features of the range, and the

presence of many smokers stands, rather suggests that

Beldray would have had a large market supplying hotels,

restaurants, clubs and pubs. Those types of users

continued to use brassware long after it and copperware had

become very much less fashionable with the passing of the

Arts and Crafts style. At what might be seen as the

other end of the social and moral spectrum, many of their

brass vases have been seen on altars and in other parts of

churches. |

|

|

It is also of interest that the company's earlier

catalogues refer to "art metalware" but the later ones refer

to "metalware in brass and copper" as if the phrase "art

metalware" had become unfashionable. |

| It is known, from the testimony of those who worked

there, that the company's own drafting office designed

everything on the "copper side" in the 1930s and this was

almost certainly the practice from the start. (It may

be relevant that the Bilston Art and Technical College was

just a hundred yards down Mount Pleasant from the Beldray

works). The company's art metalware designs seem to

have followed design fashions closely, from the Japanese

influenced designs at the beginning of production, to the

Art Deco influenced designs at the end of production.

Design was almost certainly driven by ideas of what would

sell and there is little or no evidence of any attempt to

lead fashion or to produce innovative designs. |

|

|

Production of art metalware ended in 1939. The

testimony of those working there at the time is to the

effect that less and less was being produced in the late

1930s and that production cased altogether at the outbreak

of war. |

| Mary Southall says: "1939/45 saw [Bradleys] involved with

munitions once more; alas this meant the end of the Art Metal section.

The area where all this lovely stuff was produced was called the 'Copperside'.

Soon this place was used for manufacturing bomb tails, parachute

containers, smoke bombs, etc., etc.. It was still called the 'Copperside'

by the older people of the factory until it was demolished in 1980". |

|

|

Apparently the drafting office did engage in

producing new designs for a proposed post-war

re-introduction of the line but this never happened.

|

| All of the art metalware seems to have been sold through

the trade. The known catalogues are all directed at

the trade and no flyers or advertisements have been found

which indicate any form of direct selling to the public.

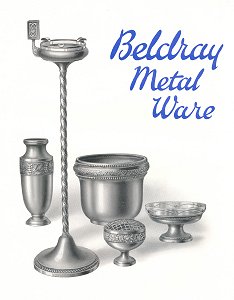

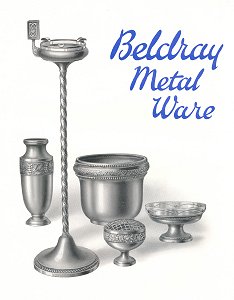

To the right is the front page of a catalogue, undated but

apparently from the 1930s, which shows a vase, a smoker's

stand, a cache pot, a rose bowl and a fruit bowl, with a

glass dish. Bradley's did not make glass and the

glassware for the many items which called for them were

undoubtedly bought in, but where from is not known. |

|

|

A number of flyers (apparently from the 1930s) advertise

"cases" containing a mixed range of items which retailers

could buy as a lot. This picture shows the contents of

Case No.6, showing a representative range of items. |

| The factory is known to have had a blacksmith's shop at

one point in its history and the wrought iron elements of

this shop would have been made there. (The copper

trays were also sold separately as "waiters"). The

company also made copper kettles on stands, some of which

were of wrought iron (whilst others were of cast brass).

Any use of cast iron seems to have ceased by the 1930s. |

|

|

Chrome plating was not introduced into industrial

production until

1925, when it soon became fashionable. Bradley's seem

to have taken it up early, as a replacement for their

"oxidised silver" finish. Some of their existing

designs in copper were produced in chrome versions, copper

being a good substrate for chrome plating. But they also

designed items for the finish, with more than a nod to the

art deco style which became fashionable at the same time. |

| The company's range included the basic items which all

makers of art metalware went in for, including water jugs or

ewers. This diamond pattern seems to be exclusive to

Beldray. The do not seem to have made much use of the

"beaten" finish popular with other makers, it seeming that

it was only used for a copper water can. |

|

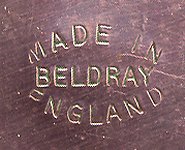

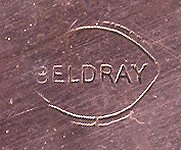

Four forms of the company' mark are known on their art metalware.

Three of them are shown here.

The circle with the bell and the dray must be, it is suggested

elsewhere on these pages, after 1918. The other two may both be

earlier but seem to have continued in use in parallel with the bell and

dray. The fourth form, rarely met, is the name Beldray in lower

case letters which are stretched vertically.

|

Beldray art metalware continues to be of

practical as well as decorative use today. |

|

|