|

Bradley & Co. Ltd

(Beldray)

Mount Pleasant, Bilston |

|

5. The Interwar Years

Mary Southall tells us that around 1920 - 1924 the

working hours of the firm were from 8.00 am to 5.30 pm Monday to Friday

and Saturday mornings. The firm was making its range of brass and

copper wares and general hollowware; with toilet pans for export to

South Africa and gas boilers as new products. "In the years

between 1920 and 1932 the firm suffered a depression as all other firms

did in this period. There was little unemployment at the firm as

at many other places; but these were hard times and all suffered because

of this. Between the period of 1932 - 1939 trade picked up a lot

and, compared to the depression, the firm went through a boom time.

The main products of the firm at this time were buckets, baths and

bowls, as by this time the skilled work which had previously been

carried out on the coppered ware was completely dying out".

That account, which Ms Southall almost certainly

collected from the oral tradition of the firm, is probably broadly

accurate but one suspects that the range of products was greater than

she indicates and that the gradual demise of the brass and copper art

metalwares was not caused by a lack of skill but by a change of fashion.

In fact Bradley's trade in these items survived a good deal longer

than that of their major competitors, including the local Joseph Sankey

& Sons.

|

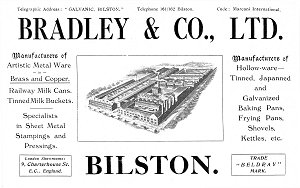

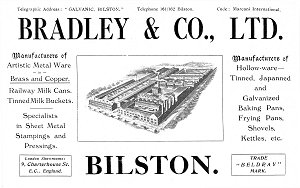

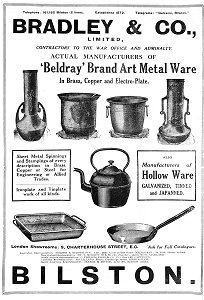

This advert (left) from 1920 lists their

products as art metalware, railway milk cans, tinned milk

buckets; tinned, japanned and galvanised frying pans,

shovels, kettles, etc.; and says that they are specialists

in stampings and pressings. (Most companies

offered to do such work for other companies to make fuller

use of equipment and labour). |

|

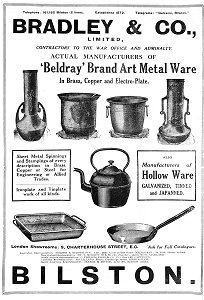

This advert, from the 1920s, shows Art

Metalware in brass, copper and electro-plate. The

reference to electro-plate is not clear.

There is also reference to household

hollowware, which they describe as galvanised, tinned and

japanned.

In both cases the items shown are

merely representative; the actual range was, in both cases,

much wider. |

|

|

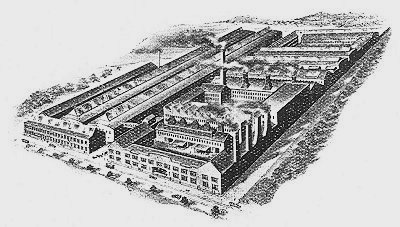

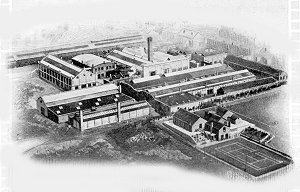

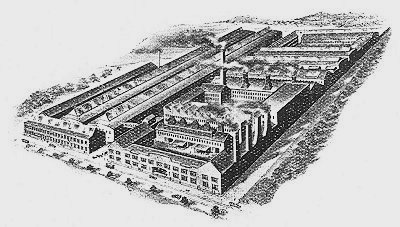

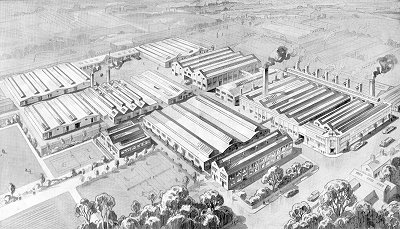

By now the factory had been largely rebuilt since its

early times as this picture from a 1920 advert shows.

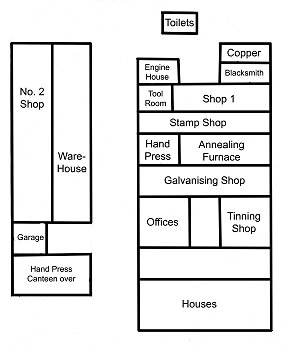

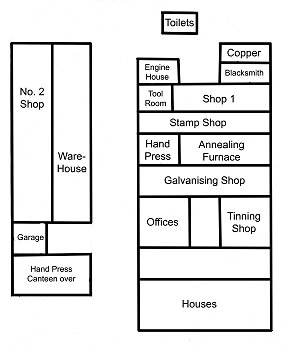

Mary Southall provided a diagram of the works as they were

in 1920 (redrawn, below).

There is only a rough correspondence between the two

images. |

| It may be that, despite the dates given, Ms.

Southall has shown an earlier layout of the site.

It seems to consist of two main blocks (with a third,

much smaller, toilet block) but exactly where these

buildings lay is not clear. All one can say is that

Mount Pleasant is at the bottom, by the houses. It is

also odd that one building is marked as having a canteen on

its second floor. If this is right it must have been

an alternative facility to that which, by Ms Southall's

account, should have been part of the bowling green, tennis

court and social club complex.

Note the small shop allocated to copper; and the

blacksmith's shop, presumably mainly for wrought iron parts. |

|

|

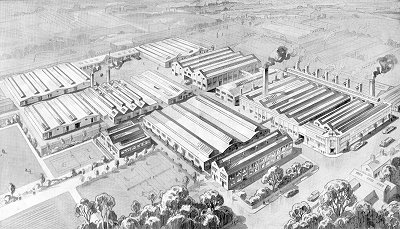

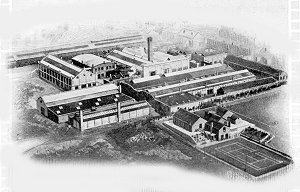

And this image, from an undated catalogue, shows

something else again. Note the tennis court, with the

bowling green to the right. Mount Pleasant runs across

the top right corner. This image has a greater air of

authenticity than the 1920 drawing above. |

| This drawing, from a later, undated catalogue, seems to

show a good deal of expansion, as well as two tennis courts.

Here Mount Pleasant runs across the bottom right corner. |

|

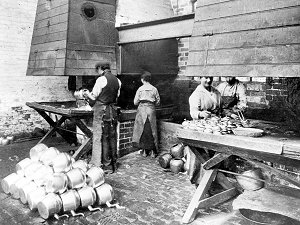

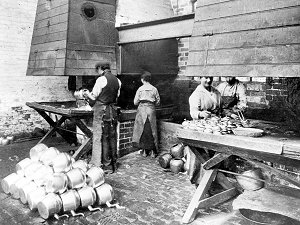

The following photos of the work's interior are undated

but are probably from the early part of the century. They almost

certainly show the same buildings as are on Mary Southall's maps.

|

Forge hearths, at the first of

which the worker seems to be shaping bucket handles and then

fixing them to the bails. The handles, in straight

form, can be seen on the hearth and the finished buckets are

piled to the right. |

| Making kettles. The workers

to the right seem to be tinning the interiors of lids.

Note the number of women workers here. |

|

|

Sheet metal bending. The

fact that women are doing this work makes one wonder if this

was during World War One. |

| Five women all engaged in making

watering cans.

|

|

George Phillpott gives a more detailed account of the

later part of this period, staring in 1932. It will be noticed

that Mr. Phillpott mentions a far wider range of goods than does Ms

Southall.

George Philpot, in much

later times, with a watering can for which he

made the tools. |

When I left school in December

1932, jobs were hard to come by. I was

lucky to be taken on by Bradley's and I started

there in January 1933, aged 14.

Conditions of employment were rather

different then to those of today. This is

not any criticism of Bradley's - it was common

practice among employers. They would take

on school leavers, such as myself, and when a

few years later they had to start paying them

adult wages, they would sack them and take on

other juveniles. I had been at work there

for several weeks before I found out that I had

been given the job from which a very good friend

had been dismissed (but there were no

recriminations).

My first job was to help to make coal

scuttles. They were called "Waterloos" because

they were shaped like the hats which soldiers

wore at the Battle of Waterloo.

After about twelve months I went into the

tool room as an apprentice tool maker.

This meant a drop in wages but it ensured that I

would still have a job after I reached the age

of 18 and that I would have a trade to my name. |

The tool room foreman was a man of most uncertain

temperament and, apparently because he frequently referred

to peoples as "proper Job's comforters", he was known as

Joey. He called everyone "Chile", in much the same way

that men today used the terms "mate" and "pal". I do

remember, however, one pearl of wisdom that he imparted to

me: "Remember this, Chile, the man who never made a

mistake, never made anything".

The company had an excellent reputation as makers of high

quality domestic wares, and the product range included

dustbins, buckets, household shovels, kettles of all sizes,

watering cans and a host of other items, including frying

pans by the thousands. Most of the products were galvanised,

though some were tinned and others, such as kettles and

coalscuttles, were black enamelled.

Some of these items we made then have now passed into

history such as the small hand bowl, with a wooden handle

about 6" long, with which the housewife would ladle the

water out of the washing tub when washing was done. Another

was the mortar bowl, a large steel receptacle shaped like a

pudding basin, which had been flattened somewhat, and about

24" in diameter. I never saw them in use but I always

understood that ladies in Africa carried them around on

their heads with goods and merchandise in them.

| Yet another was the egg bucket, a specially

designed bucket, the purpose of which was to

preserve eggs before the days of the fridge. A

substance called isinglass (which Bradley's did

not provide) was added to keep the eggs in good

shape.

Shown on the right is another of Beldray's

many products: the Rapid Vacuum Ice Cream

Freezer. It was like a huge vacuum flask.

You packed ice and salt in the bottom, round the

flask, then poured your ice cream mixture into

the flask at the top. Then you left it

until it froze. I think this device was

made in the 1920s or 30s.

Thousands upon thousands of paint cans were

made, some bearing proprietary names such as

"Walpamur".

|

|

One shop made oval tin baths and in the tool room was a

machine which I believe was most unusual. It was a

lathe made by Maud & Turner. It machined not circular but

elliptical shapes on which tools were machined to produce

the bottoms of the oval baths and oval frying pans. The rise

and fall of the revolutions of the lathe head were achieved

by a series of cams and slides. Needless to say it did not

revolve very fast. |

|

Sometime in the 1930s the frontage to Mount Pleasant was

entirely rebuilt with these offices. A splendid

example of the architecture of the period, they are now

locally listed. |

| The company retained these houses, which had apparently

been built by the company for what would now be called key

staff. Those on the right are to the north of the main

offices on Mount Pleasant and those below are to the south. |

|

|

The south block was eventually auctioned off, in lots of

two or three houses at a time (but they now appear all to be

in individual ownership). The north block was sold in 1978

to help finance new factory buildings. Mrs. Winifred

Roberts (nee Barrett) bought hers direct from Beldray at

that time. She and her husband had lived in it for

years before, her husband being one of their employees.

But she could not buy it until after he husband had died. |

| Exhibition stand, of unknown

date but probably within this period. The event may have

been a British Industries Fair. The stand shows both art metalware

and galvanised goods, including watering cans, baths, boilers, well

buckets and a milk churn.

Photo by courtesy of Jaap Arriens.

|

|

|