Crown Works - Davies

Brothers |

|

The location of Crown

Works. |

The business was founded in

1838 by Edward Davies to galvanise iron and

ironwork, with premises on Snow Hill.

Edward Davies

is credited with introducing galvanising to the

town. In fact the firm was one of the first hot dip

galvanising companies in the world.

The entry in

White’s 1851 Staffordshire Directory is as follows:

Edward Davies, iron and tin

plate worker, zinc etc., Snow Hill. |

| The firm was very successful

and moved to a larger site in 1869, between Cross

Street North and the BCN, covering approximately 3½

acres.

On the site they built a new factory called Crown

Works, next to Ceres Works, with a wharf on the

southern side of an existing basin.

There was also a second narrower basin just south

of Lock 6. |

Crown Works in 1872. From

Griffith's Guide to the Iron Trade of Great Britain. |

|

The factory entrance was situated in Cross

Street North, even though the site extended

southwards to the Cannock Road. When the factories were in

operation the whole area must have filled with

unpleasant acrid smells from galvanising, and an

equally unpleasant smell from Ceres manure works,

and the Corporation’s sewage works in Crown Street.

Most of their products carried the "Crown and

Knot" trademark, the crown being a symbol almost

universally used to denote the quality of iron and

the knot being the Staffordshire knot.

For other products they used the brand name "Nonsuch".

|

Crown Works in 1924.

|

The business is described in

Samuel Griffith’s “Guide to the Iron Trade of Great

Britain” published in 1873, as follows:

We believe Mr. Davies was the

first to introduce galvanising on a large scale to

Wolverhampton, in 1838. The trade has since become

one of the principal staple trades of the town.

Nevertheless, Mr. Davies’s article has always kept a

very high position in the market. The brand of the

Crown Works is a crown surmounting the Staffordshire

knot.

His best Crown Sheets have

always been well known and appreciated in the

market, and occupy the very highest position in the

United States of America and Australia.

Mr.

Davies likewise galvanises best, and high class

charcoal sheets. Iron is also tinned for various

purposes. Galvanised iron houses for export are made

largely at Mr. Davies’s factory, which is well

situated for railway and canal accommodation.

|

|

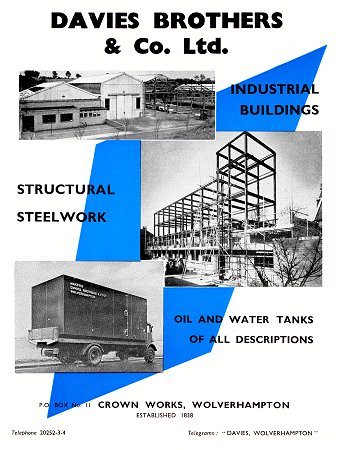

An advert from 1924. |

The iron houses referred to in

Griffith’s description were built with galvanised

corrugated iron sheets.

The firm made huts and

shelters which grew in size until houses, halls,

churches, and other sizeable buildings were made,

and exported all over the world. This part of the

business grew into the Constructional Department.

Edward Davies retired in the

mid 1870s and his two sons Edward Albert Davies and

James Davies took over the business, which became

known as Davies Brothers & Company.

In 1884 the

partnership was dissolved when James left to start

his own business.

On 7th March, 1885 a

new company, Davies Brothers & Company Limited was

formed with a capital of £100,000 in 1,000 shares of

£100 each.

The new company purchased the premises,

machinery, stock, and goodwill from Davies Brothers

& Company. |

| Edward Albert Davies became

Managing Director, and Moses Bayliss became

Chairman. He was a past chairman of Bayliss, Jones

and Bayliss.

Also on the board were his nephew

William Maddock Bayliss, the then present chairman

of Bayliss, Jones and Bayliss, and his son William

Maddock Bayliss, who became chairman of Davies

Brothers in 1895 after the death of his father. The

Company Secretary was James Saunders.

William was

one of the leading authorities on physiology and

became Professor of General Physiology at University

College London in 1912. He was knighted in 1922 for

his physiological work. |

|

Although the company had

extensive canal wharfage, products were also sent by

rail. In the 1885 minute book, guaranteed payments

are listed to the Midland Railway, the Great Western

Railway, and the BCN.

The new company got off to a

bad start, finding it difficult to compete with

other manufacturers of galvanised sheet iron. The

directors even considered moving to South Wales to

produce steel in order to manufacture galvanised

sheet steel.

The situation greatly improved

when the company patented a method of automatically

galvanising sheets of iron or steel, which could

also be corrugated as part of the process. This was

the first process of its kind in the world.

Patents

were taken out in 7 countries, and manufacturers

paid royalties to Davies Brothers for using their

system, which became very popular in the USA.

The

company was awarded a gold medal for the

breakthrough at the 1893 Chicago World Trade Fair.

As a result the company became very profitable.

|

|

| View some products from

the company's 1910 catalogue |

|

|

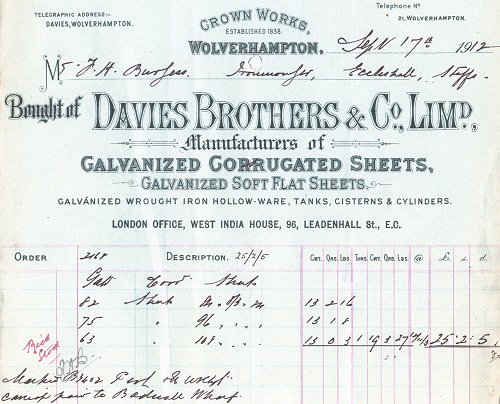

An invoice from 1912. |

In the 20th century

corrugated sheet roofing, and galvanised corrugated

sheets became successful products which were

exported to many countries.

The company’s tank and

cistern making department became very successful,

and produced a wide variety of riveted or welded

galvanised tanks, cisterns, and hot water tanks for

domestic installations.

Other products included

water barrows, feeding troughs, drinking troughs,

buckets and tubs, sanitary vessels of all kinds,

gutters, and downpipes.

|

| Davies Brothers also began to

produce none-galvanised products. The Constructional

Department began to manufacture steel framed

buildings that were cladded with asbestos cement

sheets.

Some of the tanks for storing liquids, such

as oil and petrol, were too large to be galvanised. |

The site of Crown Works, as

seen from lock 6. |

|

The derelict site of the

factory in 2009. |

The canal basins were still in

use in the early 1930s when the acid used in the

works was conveyed by narrow boat from Oldbury by

Thomas Clayton, and coke was conveyed from Stafford

Road Gas Works by George and Mathews. The waste acid

was also transported by canal, on Fellows, Morton

and Clayton boats to Courtaulds in Horton Road. The

same company transported the galvanised sheets for

export to Ellesmere Port.

|

| After the Second World War

sales started to decline.

In 1946 Peter Davies the

great grandson of the founder, Edward Davies joined

the management team.

He was the last member of the

Davies family to work for the company. He left in

1964. |

The site of the large basin. |

|

An advert from 1935. |

The company’s entry in the 1949

Wolverhampton Handbook is as follows:

Davies Brothers & Company

Limited, Crown Works, Wolverhampton. Manufacturers

of riveted or welded tanks for storage of water,

petrol, or fuel oil, galvanised cisterns, cylinders

and hot water tanks for domestic hot water supply,

galvanised gutters and downpipes, galvanised cattle

troughs, garden and water barrows, steel hay barns,

roofs and buildings.

In 1963 the company acquired

Gittins and Mellor Limited to replace the

Constructional Department which closed. Gittins and

Mellor shared the factory and the offices with the

parent company, and manufactured ‘Liteway’ steel

flooring, tubular steel handrailing, and

constructional steelwork.

|

|

The Davies Brothers letterhead

from 1978 lists the following products:

Oil tanks, petrol tanks,

galvanised cisterns, cylinders, tanks and cattle

troughs, corrugated cisterns, galvanised feeding

appliances, swing water barrows, coal bunkers,

street bins, water cart bodies, pipes and hoppers,

galvanised sinks, steel platework, open-type steel

flooring, handrailing, handrail standards,

structural steelwork.

The company closed in 1981 and

the factory became a scrap yard.

The site was

acquired by Wolverhampton Council in 1993.

The

factory has since been demolished and the area

cleaned of toxic substances.

It has been used as a

car park, but is now derelict. |

An advert from 1965. |

From the 1965 Wolverhampton Handbook.

|

|

|

|

An advert from 1970. |

|

An advert from 1972. |

|

An advert from 1974. |

| From the 1974

Wolverhampton Handbook. |

|

A final view from the canal looking

towards lock 7.

|

|

Return to the general metalware section |

|