|

|

Bayliss Jones and Bayliss Ltd.Victoria Works, Cable Street |

|

The Company's Historyby Helen Priddey page 2 |

|

Though a subsidiary of G.K.N. from 1922 the company kept its own name and the Bayliss family continued to provide its management. Samuel died in 1932. His younger brother and Horace W. Bayliss were directors. P.S. and F.W. Bayliss, Samuel's sons, joined the board in 1921 and 1925 respectively, and they became the joint managing directors in 1928.

|

|

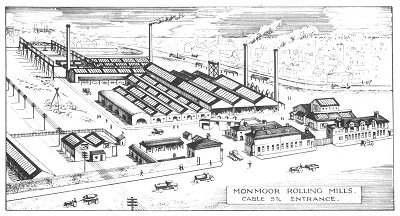

The Monmoor Rolling Mills on Cable Street. Note the canal, with covered wharves, to the right. |

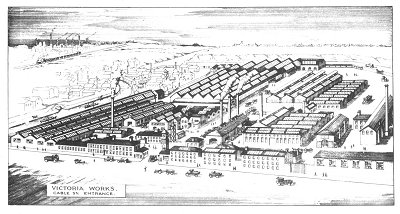

| The (main) Victoria Works on Cable Street. The canal is to the left. |

|

|

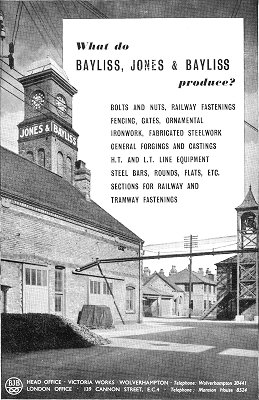

A view of the main entrance on Cable Street, with the clock tower. |

| These interior views are not captioned. No doubt the interior was not quite as clean, light and spacious at it appears here. |

|

|

These appear to be drop forges of some sort. |

| In the 1930s the company engaged Heath Robinson to produce more fanciful drawings of how gates and fences were produced. They appeared in Punch and maybe elsewhere. |

|

| The early 1920s were a difficult time for the company and at the urging of the parent company new equipment was installed and the company's production methods modernised generally. They also seem to have concentrated more on the fencing, railing and general ornamental ironwork side. In the great slump of 1929-30 they were hit hard but recovered strongly in the later 1930s. |

|

This advertisement from 1948 shows their Victoria Works in Cable Street. The clock tower was a common feature of Victorian factory buildings in many places but they do not seem to have been common in Wolverhampton. Note that, even in this dressed up view, it is possible to see how, like many works, this one seems to have been built up bit by bit. |

| A view of the interior of their works from 1953. This, of course, is only part of their works - and probably one of their more modern shops. |

|

|

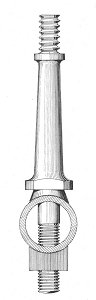

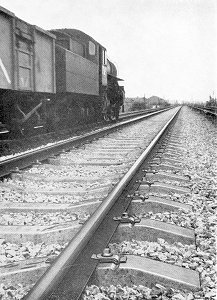

By 1953 the firm employed about 1,500 people and provided a canteen, bowling green, netball court, sports ground with cricket, football and hockey pitches, children's playground, tennis court and even a miniature golf course for them. A large proportion of the work at this time was for county councils, carrying out their 'improvements' of substituting railings for hedges. Demand for balustrading to span the many new bridges extending over Britain's motorways also kept the firm busy. The products which the 1953 Wolverhampton Official Handbook mentions include: plain and ornamental wrought iron fencing; for railways - black bolts and nuts, screw spikes, chair bolts, fishbolts and other fastenings; equipment for overhead telegraph and telephone lines; fabricated steelwork; general forgings; agricultural equipment - tractor toolbars, heavy tractor cultivators, plough beams and brackets, hay rake frames, etc.; and a recently created department for the welded steel fabrication of machinery frames, bed-plates, mill plant, constructional steelwork, agricultural implements, containers, stillages, hoppers and guards. |

|

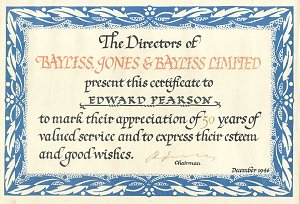

The company employed large numbers of people but doubtless few of them stayed there as long as Edward Pearson. This certificate, from 1946, is far less elaborate than those used by other companies. But this may simply reflect post-war austerity. |

|

All of these things (whatever many of them were) were helped along by the company's having its own steel rolling mills, with a capacity of 1,000 tons per week. Since they might get orders for miles of railings at a time, the amount of metal being used in the works must have been enormous.

In addition to their standard lines of railings and gates, they also made one off pieces to the designs of the individual customer (or, very often, his or her architect). The firm kept its name until 1968. |