|

Joseph Sankey & Sons Limited

is well-remembered in Bilston, as one of the larger and most

successful manufacturers in the town. The firm’s factories at

Albert Street and Bankfield were once prominent landmarks,

overlooking the town centre.

The Early Years

Joseph Sankey was born in Bilston in 1827.

Unfortunately his father died in 1836 and so Joseph became a

pupil at the Royal Orphanage School in Wolverhampton. At the age

of 14 he was apprenticed to John Duncalfe, a tray blank maker of

Hall Street, Bilston, where he was taught design and mechanical

drawing. After his apprenticeship he was employed by the Birch

brothers, who made tinplate trays that were sold to japanners

for finishing.

The business failed, and two of the senior

employees, Charles Harthill and Samuel Jackson, set up their own

firm in Middlefield Lane, where they employed Joseph Sankey.

Charles Harthill died in 1854, at a time when the firm owed £800

to Jon Bates, a sheet iron merchant, who secured possession of

the plant and tools of the firm as security for the debt. He

recognised Sankey's skills and determination, and in 1854

persuaded Jackson to take him into partnership. The new firm,

with premises in Dudley Street, Bilston, concentrated on the

production of blank trays, stamped from tinplate, that were then

sold to japanners. Jackson & Sankey produced trays of many

different shapes and sizes, but struggled financially, having to

repeatedly re-mortgage the firm's premises to finance expansion.

In 1861, Joseph Sankey began to run the

business on his own, after buying-out Samuel Jackson, who

continued to work for the firm as a foreman in the blank tray

shop. In the early 1860s, Joseph went into partnership with

Richard Chambers and John Page in order to acquire a rolling

mill and ironworks at Stonefield, as a way of gaining control

over the firm’s supplies of tinplate and sheet iron. The

business became the Bilston Iron Company. |

|

An advert from 1876. |

|

Expansion

Until the early 1860s, Joseph Sankey

appears to have lived on the Dudley Road site. In the early

1860s he had a new home built in Wolverhampton, which was called

Goldthorn House. It stood on the southern side of Goldthorn

Hill, next to where Coton Road stands today.

In 1867, Joseph Sankey acquired land in

Albert Street, behind the Dudley Street premises, where a large

workshop was built. Steam-powered stamping machines were

installed so that heavier gauges of metal could be worked. New

products included frying pans and kettles.

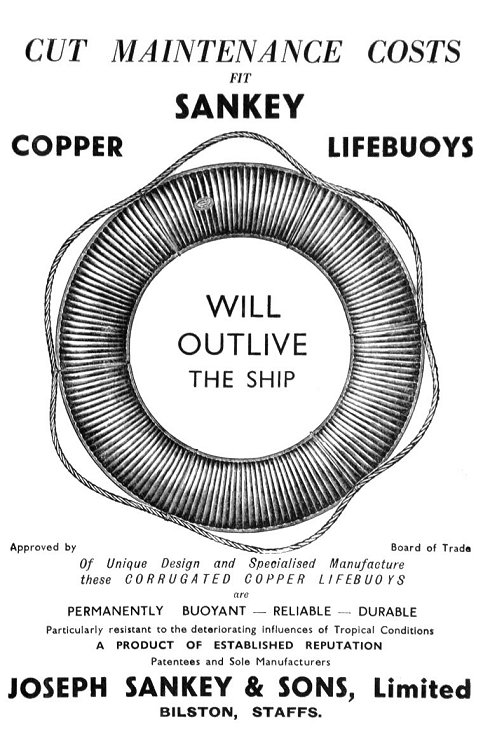

The firm began to concentrate on the

manufacture of a wide range of hollowware including chocolate

moulds, dish covers, lamps, lanterns, milk churns, tin boxes and

stamped or pressed metal products such as bath tubs, fire

shovels and metal life buoys. A significant export business also

developed. Cassada pans that were used to dry coffee beans were

exported to Brazil and bowls were exported to Ceylon, China and

India.

In 1871, Joseph’s eldest son, John William

Sankey, joined the firm and took over the accounting. In 1874

the firm had 65 employees. In 1878, John William Sankey became a

partner in the business and in 1884 his younger brother George

Herbert Sankey joined the firm. The company’s founder, Joseph

Sankey, died in 1886.

In December of that year, the company

started out in a new direction after being contacted by Robert

Jenkins, an iron merchant from London. He had been researching

into the possibility of making armatures for dynamos from

charcoal sheet iron discs. He thought that Sankey’s existing

stamping machines could be easily adapted for the manufacture of

electrical laminations and in 1887, persuaded Siemens to place

an order for laminations through an agency called Harold &

Jenkins. By 1890, contracts had been signed and production of

the laminations began. In the mid 1890s, Sankeys abandoned

charcoal iron in favour of a metal steel sheet.

Further Expansion

In July 1891, John William Sankey, went

into partnership with his two younger brothers, Frederick Ernest

Sankey and George Herbert Sankey, and the business became Joseph

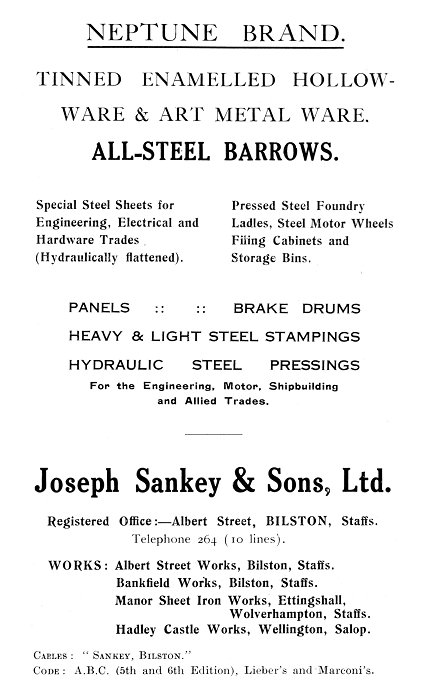

Sankey & Sons. The firm acquired a number of smaller businesses

including Edward Morris & Sons, manufacturers of sugar-making

utensils; Huttons, manufacturers of nickel plated trays; the

Sanitary Bath Company, manufacturers of copper-clad steel; and

J. H. Hopkins & Sons of Granville Street, Birmingham,

manufacturers of hollowware and japanned products that had the

'Sphinx' trademark, which was adopted by Sankeys. The japanning

side of this business was sold, and stamping and pressing was

concentrated at Albert Street Works. |

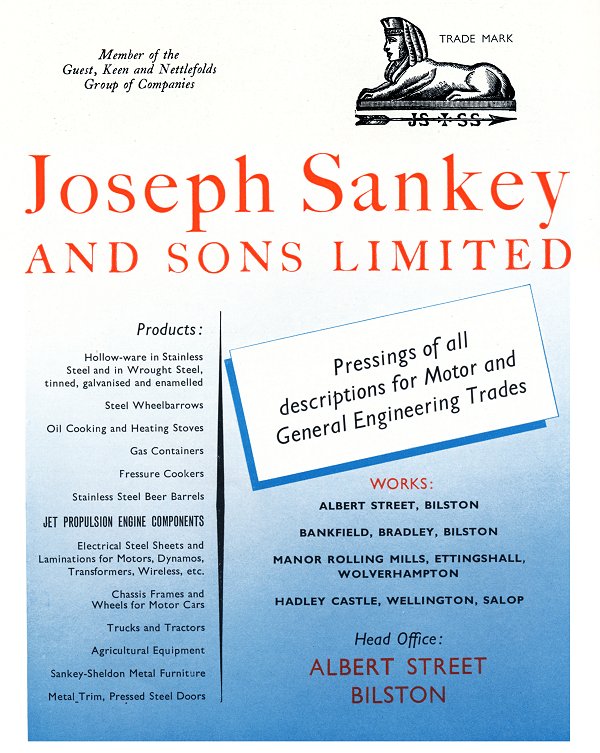

|

Sankey's trademark. |

|

In 1890, Sankeys patented a process called

'Neptune Ware' in which tinplate ran through colour rollers to

undercoat both sides. After being embossed and painted,

products, such as ash-trays, bread baskets, candlesticks, cups,

children's money boxes, cake baskets, and waiters' trays, were

blanked out to the final shape. The technique was a great

success and part of Albert Street Works had to be expanded to

cope with the growing demand. Also at this time, the firm

produced more kettles than any other British company, thanks to

the use of cheap steel that could easily be pressed into any

shape.

A New Factory

In 1893 the firm erected a large and

comfortable room for the use of the employees as a mess room and

a recreation room. A library was also built for the use of the

employees. Expansion continued in the early years of the new

century. In 1900 the derelict iron and tinplate works at

Bradley, established in 1833 by Thompson, Hatton & Company were

acquired for expansion. Most of the existing buildings were

demolished, and a new factory was built on the site for the

manufacture of electrical laminations. Slotting machines and

keyway cutters were acquired in order to transfer the

manufacture of laminations from Albert Street Works to the new

site, which was called Bankfield Works.

In September 1902, Joseph Sankey & Sons

became a limited company with an authorised capital of £200,000

divided into 10,000 ordinary shares of £10 each and 10,000

preference shares of £10 each. J. W. Sankey became Chairman and

George and Frederick Sankey were appointed as Directors, along

with John Chambers, who after working for the firm for many

years, had risen to Company Secretary.

To assist in the production of laminations

at Bankfield Works, Manor Rolling Mills at Ettingshall were

purchased from Stephen Thompson & Company Limited, in 1904. The

factory provided production facilities for the silicon steel

sheets that were needed for the electrical laminations.

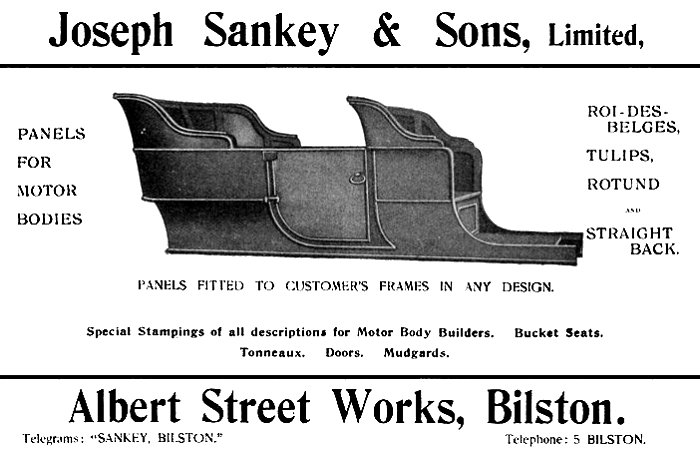

Also in 1904, Sankeys began to manufacture

pressed body panels and wood and coach ironwork for cars. Within

two years, the firm was exporting body panels to Paris and New

York.

In 1906, Sankeys were granted an exclusive

licence from the Hadfield Steel Foundry of Sheffield for the

manufacture of a special electrical steel, known as 'stalloy'.

In 1909, Sankeys sub-licensed John Lysaght to roll sheets under

the Hadfield patents at their Orb Works, in Newport, South Wales

and also granted a licence to the Brymbo Steel Company, near

Wrexham, to make steel bars and blooms under the Hadfield

patent, which were to be sold to Lysaghts for rolling into

sheet. |

|

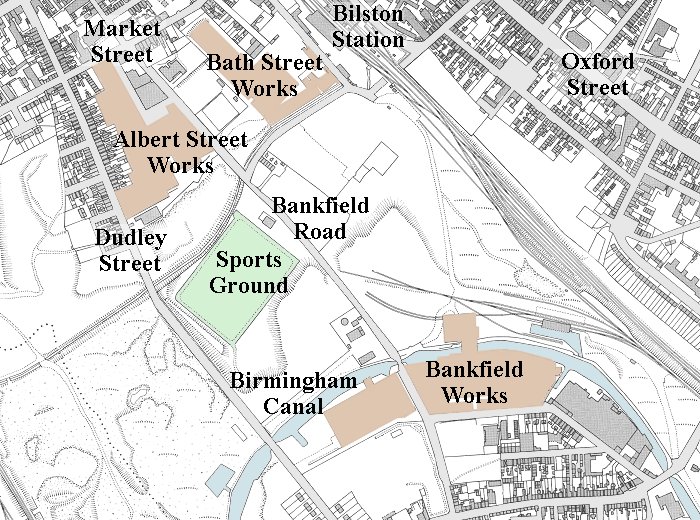

The Bilston factories. |

|

More Automotive Parts

Sankeys extended production of automotive

components at Albert Street after developing and patenting the

first pressed and welded, detachable motor car wheel, the 'All

Steel Wheel', in 1908. In the following year the company started

stamping steel body panels for Arrol-Johnston cars. Production

of automotive components increased again in 1910 when Sankeys

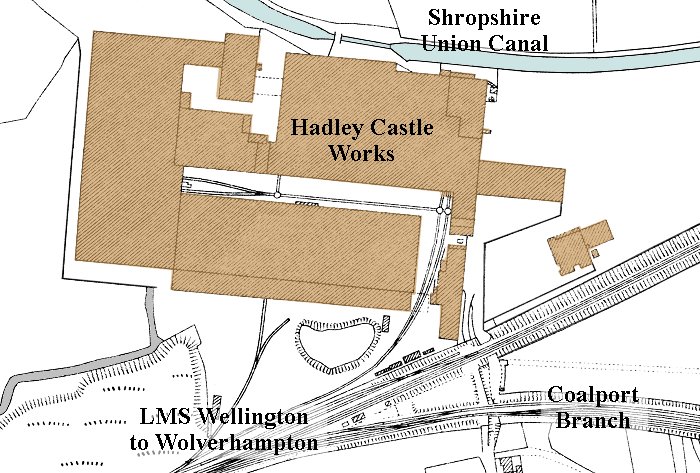

acquired the former factory of the Castle Car Company, at Hadley

Castle, near Wellington, which had produced tramcars. Some of

the machinery had remained in the factory, so production of

pressed steel car and charabanc body panels and the steel wheels

soon got underway there. The factory was also used for the

production of the range of Sankey-Sheldon office furniture and

agricultural implements.

In 1911, the automotive body shop was

transferred from Bankfield Works to Hadley Castle, along with

the wheel shop from Albert Street Works. Production of

automotive components was now concentrated at Hadley Castle. By

1914 the demand for laminations for dynamos, motors and

transformers, as well as for small electrical stampings had

significantly increased.

|

|

Hadley Castle Works in the 1930s. |

|

An advert from 1908. |

|

From the Autocar, 6th November, 1909. |

|

In 1913, after the death of John William

Sankey, his brother George became Chairman. At the outbreak of

war in 1914, a large number of employees went into the armed

forces, which greatly affected production. The firm received

large orders for war work from the Ministry of Munitions and in

November 1915, Albert Street Works became a Controlled

Establishment.

Products produced both at Albert Street and

Hadley Castle included aeroplane parts, bombs, field kitchens,

mine hemispheres, mortar bombs, rifle grenades, steel helmets,

anti-submarine bodies and shell bodies. A large number of female

workers were employed to replace the male factory workers who

had joined the armed forces. By the end of the war, 69 employees

had been killed, including Sydney Sankey, the eldest son of John

William Sankey.

Amalgamation

After the war, the company was still

profitable, but George Sankey had no desire to remain in charge.

There were few managers at board level and possibly some

uncertainty about the company’s future in the post war era. The

Sankey family decided to sell the business to one of their main

suppliers, John Lysaght & Company with whom they had strong

ties. In 1919, Lysaght’s Chairman, Henry Seymour Berry, also

became Chairman of Sankeys and Joseph Sankey & Sons Limited

became the sole subsidiary of John Lysaght Limited.

Henry Seymour Berry very much wanted to be

associated with Guest, Keen and Nettlefolds and planned to

takeover GKN. The two companies decided to amalgamate and so on

the 1st January, 1920, John Lysaght Limited and Joseph Sankey &

Sons Limited became subsidiaries of GKN. Sankeys retained its

identity and the company’s Registered Office remained at Albert

Street Works. Members of the Sankey family remained as managing

directors, until 1954.

By the 1920s, sales for the firm’s

hollowware had greatly declined. More goods than ever were

imported and plastic items were becoming more commonplace.

Sankeys decided to cease production of enamelled hollowware and

sold the excess stampings to Macfarlane & Robinson. The market

for 'Cassada' pans for Brazil remained buoyant, and large

numbers of casings for petrol pumps were sold to W. & T. Avery.

|

|

An advert from 1921. |

|

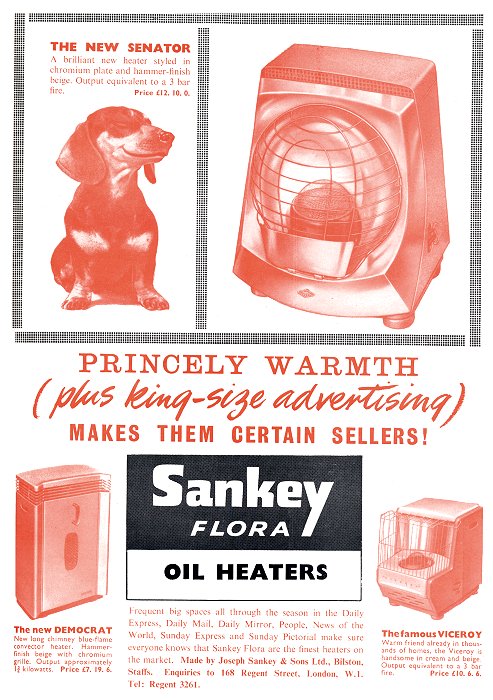

In the search for new products, an

agreement was made with the Asiatic Petroleum Company and the

Florence Stove Company, to make paraffin-burning heaters that

were sold by the Florence Stove Company. In 1929, Sankeys

purchased Bath Street Works, formerly occupied by Holcroft’s

Steel Foundry Company, and later by the Staffordshire Stainless

Iron Company. The buildings were next to the Albert Street

Works, and were used for the production of steel wheelbarrows.

|

|

The recession in the late 1920s and early

1930s led to a period of short time working and some

redundancies, which ended as the economy improved towards the

mid 1930s. At this time both Albert Street and Bath Street Works

were modernised. New presses and a new boiler house were added

along with toolmaking and repair facilities.

Investment was also made at Bankfield Works

due to the efforts of Mr. E. W. Richmond, who had been appointed

as general manager there in 1922. He convinced existing

customers to continue to purchase their electrical pressings

from Sankeys and to invest in new machinery to improve

production. By this time pressings were also being made for

wireless manufacturers.

Investment was also made at Hadley

Castle Works where three new rim-making machines were installed.

Production at the works included bath panels, metal trim,

radiators, steel barrels for the palm oil trade in Africa, steel

pulleys and steel roofing sheets.

By 1936 Sankey’s workforce had grown to

nearly 1,500. In 1938, Sankeys acquired a one-third interest in

the Florence Stove Company, which became the Florence Stove &

Hardware Company. The production of paraffin heaters became a

substantial part of production at Albert Street Works.

|

An advert from 1929. |

|

An advert from 1938. |

|

An advert from the early 1930s. |

|

Another advert from the early

1930s. |

|

George H. Sankey died in 1934. By this time

his three sons, Harold B. Sankey, George Ronald Sankey and

Geoffrey B. Sankey had been in the business for some time.

Harold B. Sankey became Managing Director after his father's

death. Between 1942 and 1944 he was appointed Regional

Controller for the Midlands by the Ministry of Production.

Ronald Sankey then took over as Managing Director.

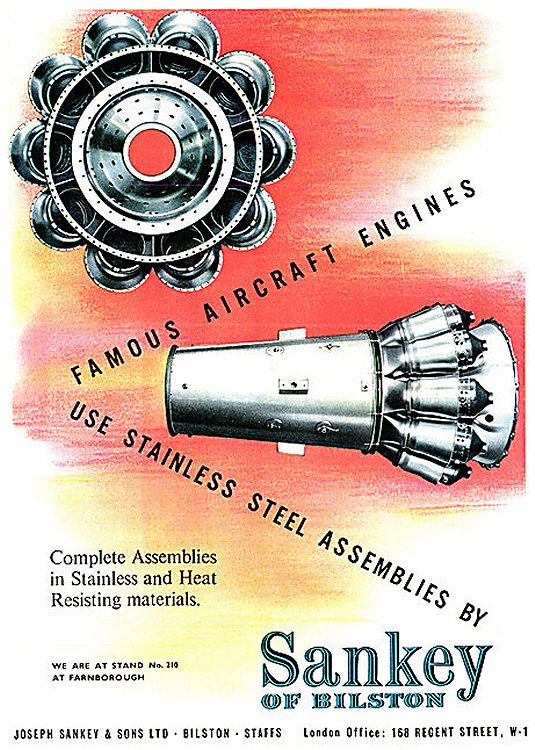

In the late 1930s, in readiness for the

outbreak of war, the government funded several new buildings at

Albert Street that would be used for war work. Products included

aeroplane spinners for De Havilland and Rotol, parts for jet

engines for the De Havilland DH1, heavy wheels for army

vehicles, ammunition boxes, bombs, depth charge cases, charges

and throwers, mines, steel helmets, complete spitfires, and

bridge sections and floats for the Admiralty. Other products

included electrical stampings for wireless sets and radar, and

steel furniture for the Royal Navy. By the end of 1940, 85

percent of the output was for war work. Orders eventually

declined after the end of hostilities in Europe in May 1945.

|

|

In 1946 a new wheel shop was built at

Hadley Castle Works that was further extended in 1955 and 1959.

In 1947 a range of agricultural implements was introduced there

including ploughs, seed drills, tractors, and trailers.

Expansion continued at the works for some time.

In 1958 a new

steel furniture factory was built, and in 1961 a new Commercial

Cab Shop opened. New plant was also installed for the production

of road wheels for buses, cars, tractors and trucks.

Hadley

Castle Works also produced mobility vehicles, armoured vehicles

including the 'Warrior' tank and automatic vending machines.

Sankeys acquired Universal Brewery

Equipment Limited in 1954, and began production of the ‘Sankey

System’, consisting of beer packaging, kegs, and combination

units for kegs to be washed, sterilised and refilled.

Plastic

mouldings for domestic appliances and office equipment became

important products along with steel furniture for marine cabins

and accommodation modules for oil rigs.

Partitioning was also

produced for general office and factory use.

|

An advert from 1938. |

|

An advert from 1951. |

Albert Street and Bankfield Works were

rebuilt in 1957 to 1958, along with a new

head office. In 1968, Joseph Sankey & Sons Limited became GKN

Sankey Limited, and by 1970, Hadley Castle Works became the main

centre of operations, employing a much larger workforce than at

Bilston.

In 1971, the company took over the production of heavy

wheels for earth moving equipment etc. from Dunlop, who took

over production of Sankey car wheels.

By the 1970s the company was divided into

the following divisions: wheel; pressings; Bankfield; plastics;

brewery; unistrut; Sankey Sheldon; and automatic vending.

The

Sub-Group headquarters was at Hadley Castle Works.

|

|

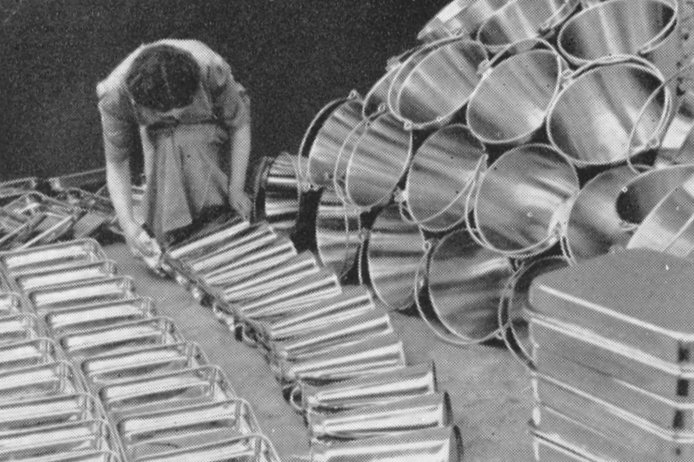

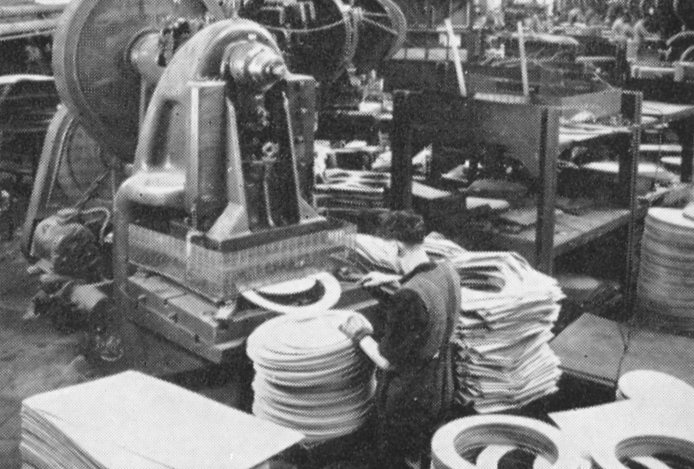

Stainless steel hospital ware made at

Albert Street in 1953. |

|

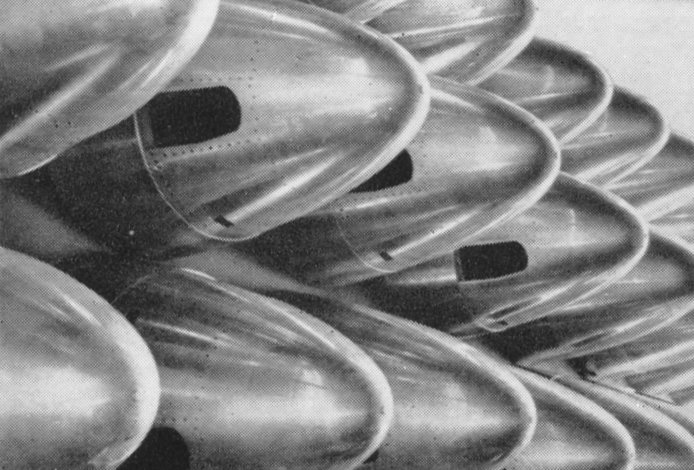

Electrical laminations made at

Bankfield in 1953. |

|

Aircraft propeller components made

at Albert Street in 1953. |

|

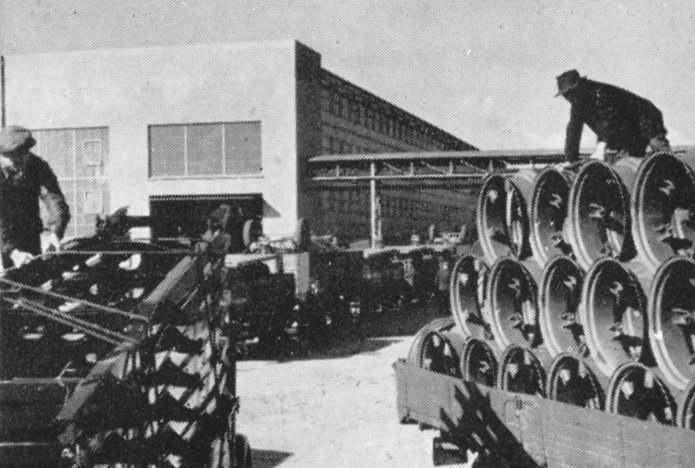

Chassis, tractor wheels and

trailers made at Hadley Castle in 1953. |

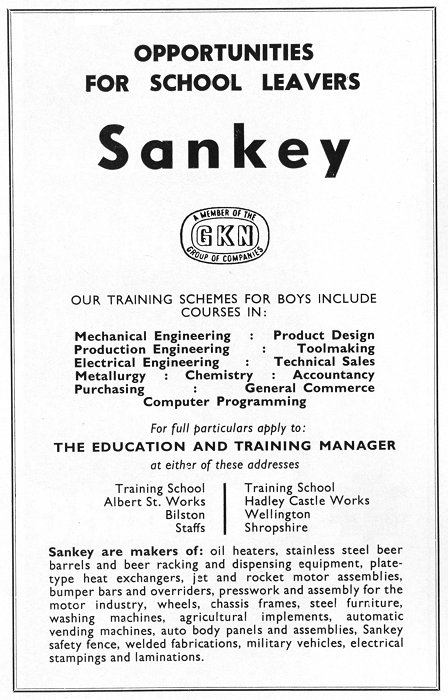

An advert from 1958.

An advert from 1965.

|

A Senator domestic heater

made at Albert Street in 1968. |

|

An advert from 1953. |

| An advert from 1955. |

|

|

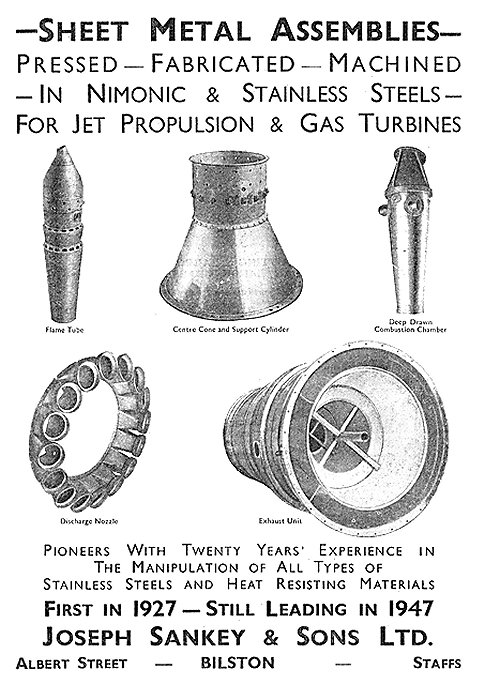

An advert from 1947. |

By the 1980s the company was suffering as a

result of the general decline of UK manufacturing. In 1980 and

1981 there were redundancies at Hadley Castle Works and Bilston,

due to losses in the wheel and pressing divisions.

Albert Street

Works closed in 1988 and buildings on the site were demolished.

The brewery business was sold and presses were moved to the

Hadley Castle Works in order to produce body pressings in a

joint venture with Jaguar.

Hadley Castle Works was divided into

four units consisting of light fabrications, making telephone

kiosks; agricultural products, supplying tractor cabs for Ford

and Massey Ferguson; engineering products, producing car

components; and the wheel division, concentrating on tractor and

off road wheels.

The venture with Jaguar failed after Jaguar was

taken over. |

|

An advert from the 1960s. |

|

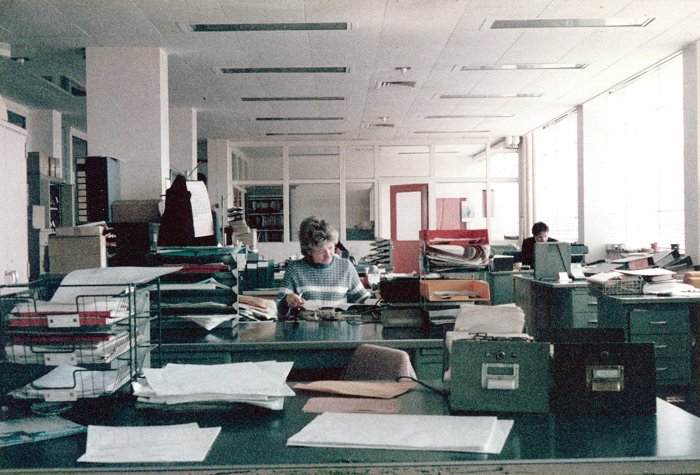

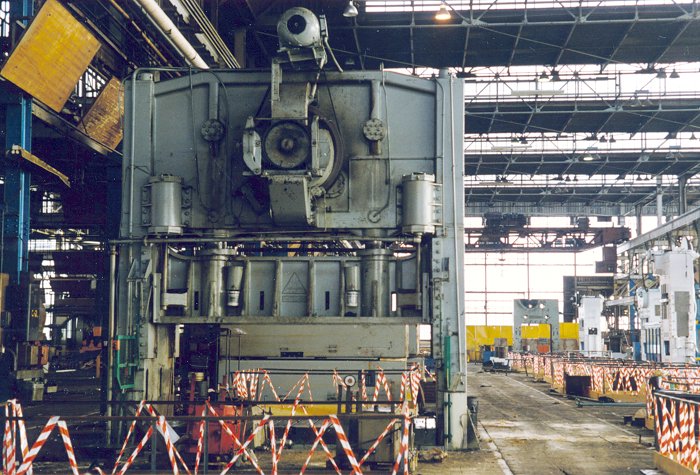

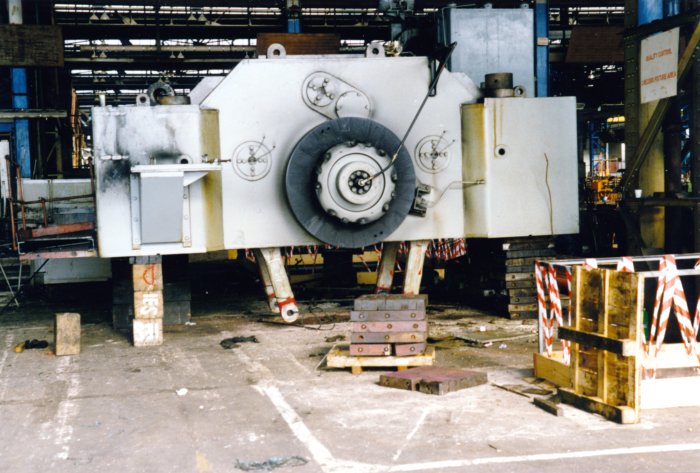

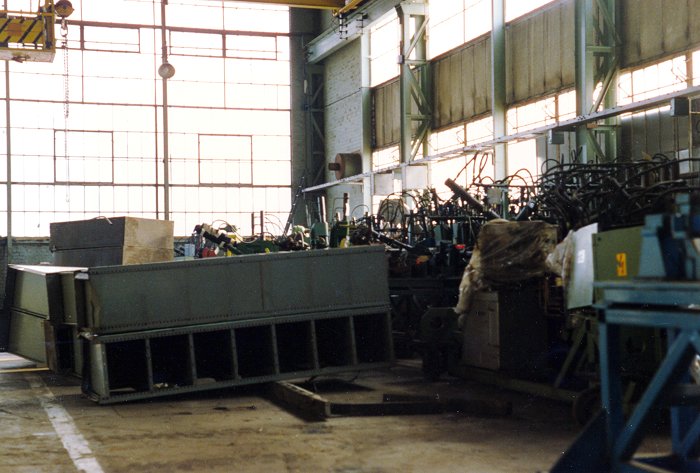

Photos from 1988 and 1989, when Albert Street Works

closed.

The lovely photos that follow, were kindly sent by David

Clare. They were taken by Sam Skitt, before and during the closure of

Albert Street Works and so must be some of the last photos

taken there. It was a sad time, when Sankeys vacated Bilston

after running the business for 134 years. During that time,

the firm had grown and had previously been one of the town's

largest employers. |

The front of the offices.

Inside one of the offices.

A row of locally made Wilkins and Mitchell presses

in one of the press shops.

Another view of the press shop.

A Cowlishaw Walker press, which is about to be

dismantled.

Another press awaits its fate.

Another machine is dismantled.

A final view of the press shop.

Part of a Lake Erie hydraulic press.

The press in the previous photo, now stands in an

almost empty shop.

A general view, as the factory is dismantled.

More machines are broken-up.

The overhead crane in another nearly empty shop.

Another view of the same shop.

The end of the shop with part of the crane on the

right.

Some of the switchgear that once supplied power to

the machines.

Another view of the shop and the switchgear, that

would soon be gone.

One of the other empty shops.

Steel rolls awaiting transportation.

A pile of scrap awaits removal.

Another pile of scrap.

A final view of the almost derelict building.

The exterior of the factory in its last days.

A final view of the factory, which awaits

demolition.

|

In 2001, Hadley Castle Works became GKN

Auto Structures.

In 2002, Ford and Massey Ferguson ceased to

produce tractors, so the main agricultural business came to an

end and GKN cabs division closed.

A small celebration was held

at Hadley Castle Works in 2004 to commemorate the 150th

anniversary of the founding of Sankeys.

At the time, around

1,600 people still worked on the site. The factory still

survives (December 2019) and is now part of GKN Aerospace.

In 2005 Corus closed the laminations

factory at Bilston with a loss of 190 jobs. |

An advert from 1953. |

|

An advert from 1970. |

|

Social Activities

Sankeys had a good relationship with the

local communities in both Bilston and Wellington. Annual outings

were organised for employees and the staff canteen at Albert

Street opened in 1893. The firm contributed £25 a year to a sick

benefit club and a sports club was first founded in 1893. In

1935 land between Albert Street and Bankfield Works, that had

been purchased in 1921, was levelled for a sports field with a

pavilion for the Sankey Social and Sports Club, which opened on

the 6th June 1936. Entry to the social club was not restricted

to employees and so it became very popular with the local

population. There were dances with live bands, bingo, and social

groups including choirs, ballroom dancing groups, music groups,

and clubs focused on hobbies and leisure interests. Sadly the

Social and Sports Club closed in 1988 and the buildings were

demolished. The company had its own St. Johns Ambulance section

and a fire brigade. |

|

|

|

Return to

the

previous page |

|

Read

about Sankey's

art metalware |

|