3. A trip round the works Most of these photos, which are some of those I rescued from a skip when the company was closing down, were taken in 1953 but one or two may come from a few years later. They give some idea of the company's works, at a time when they were expanding rapidly and were at the forefront in the production of new types of work.

Production Planning Office. The man standing centre is Cyril Evans. The jobs to be done by each machine were listed in strips on the panels to the right and the corresponding details were put in the boxes below them.

left: the paper store for flat paper, which came in reams (500 sheets). right: a small part of the reel warehouse. The more Wilkes undertook in the way of continuous stationery, the more reels were needed and eventually a very large warehouse was built to house them.

Hand composing of type. There was always a call for the skills of the hand compositor, no matter how automated printing processes became. The compositor is Robert Evans, an original Wilkes' employee from the Orchard days.

Putting composed pages, of type and blocks, into machine chases for printing. On the right is Bernard Humphries, who was the longest serving employee. He started with the firm when they were still in the Orchard. On the left is Jan Klimovicz.

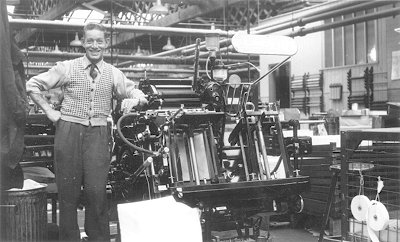

A Linotype machine, operated by Stan Fish, which set type automatically from a keyboard. Wilkes also had Monotype machinery.

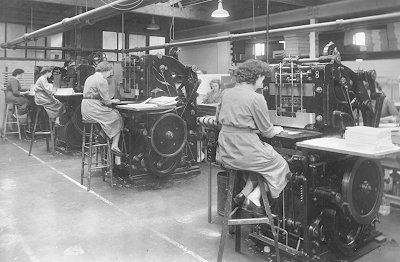

These are die stamping machines which produced the raised (and very glossy) print you often saw used on letterheads, business cards and the like, when you wanted an impressive, high class result.

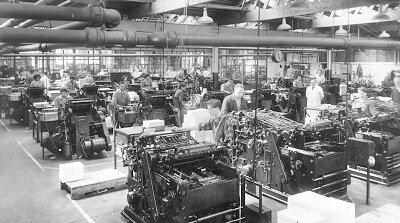

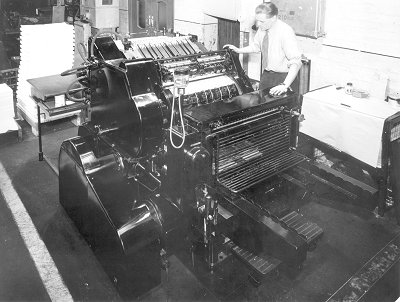

Rotary printing machines - amongst the first installed in the UK. Here they are equipped to trim reel edges to size. In the centre is Harry Bowen and far right is Tom Moorhouse.

|