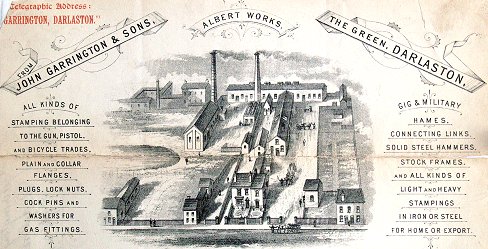

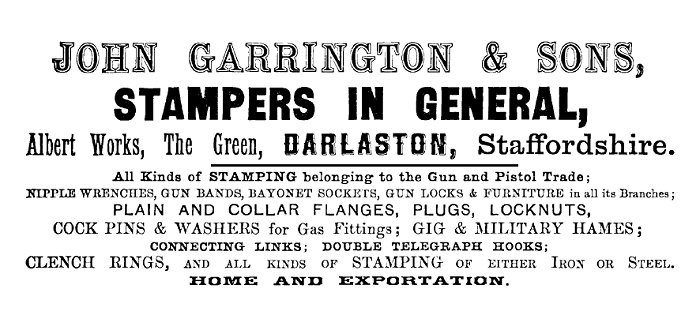

A letterhead from 1874. Courtesy of the

late David

Evans.

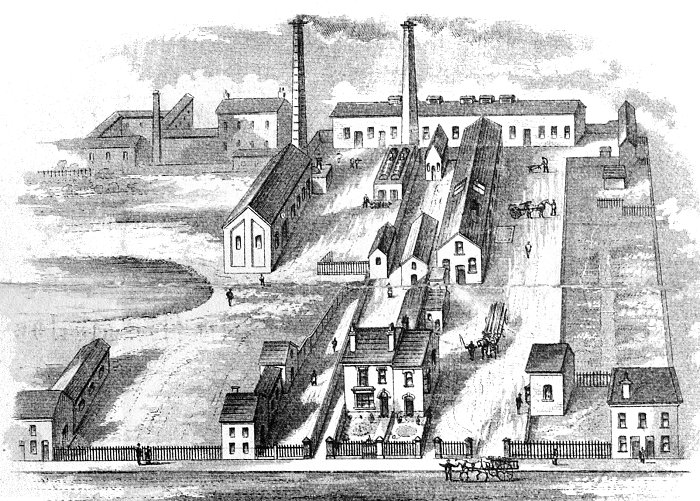

The factory in 1874.

|

Another of Darlaston's factories that closed in the

1980s recession was Garrington's forging works in

Willenhall Road. The company was founded by John Garrington

(18th May, 1799 - 1877) who set up a small stamping

business at Phoenix Works, Catherine's Cross in 1830

producing forged components for the gun trade. By

1851 the works also produced nuts & bolts and bed

screws and employed three men, including two

apprentices: Charles Tuffield (age 15 born Tamworth)

and John Camp (age 14 born Tamworth).

In 1820 John married Ann Wilkes at Wolverhampton.

They had four children: Adelaide (born c. 1932),

Fanny Garrington (born c. 1835, Richard (born c.

1835), and Benjamin Garrington (born in 1839).

In the early 1870s, the firm moved to the larger

Albert Works in Willenhall Road, where by 1881 they

employed 22 men and 10 boys. After John's death in 1877,

his two sons Richard and Benjamin took-over.

|

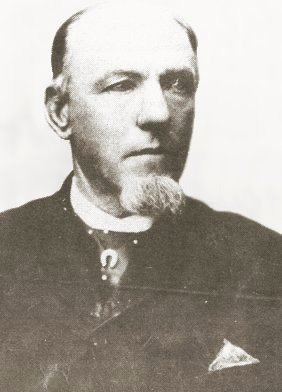

John Garrington. |

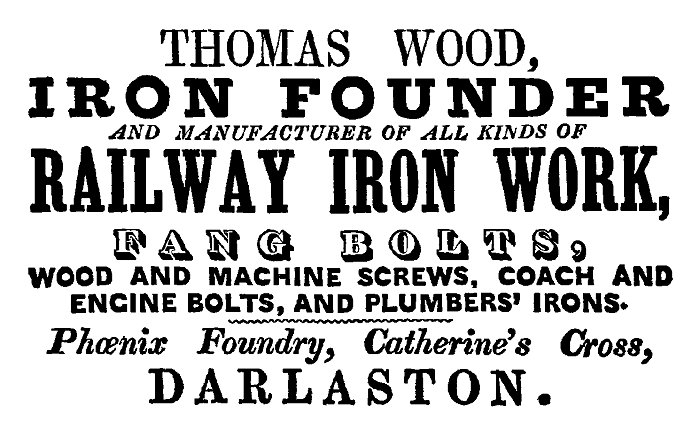

Part of Phoenix Works was

occupied by Thomas Wood, as can be seen in

this advert from Slater's Classified Directory

of the Manufacturing District, 15 Miles Around

Birmingham. Published in 1851. |

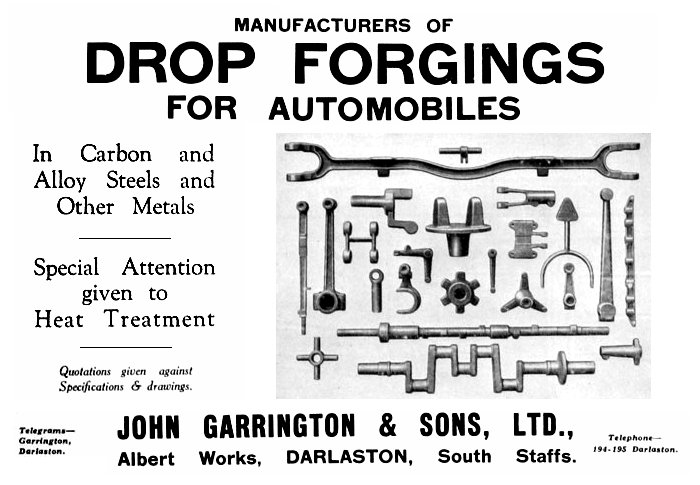

An advert from 1896.

An advert from 1904.

| Richard lived at number 49 Willenhall Road with his

wife Eliza and their two children Bertram and Catherine,

and later at The Hollies, Walsall Road.

Benjamin lived at number 21 Willenhall Road with his

wife Ann and their 8 children; 3 sons and 5 daughters.

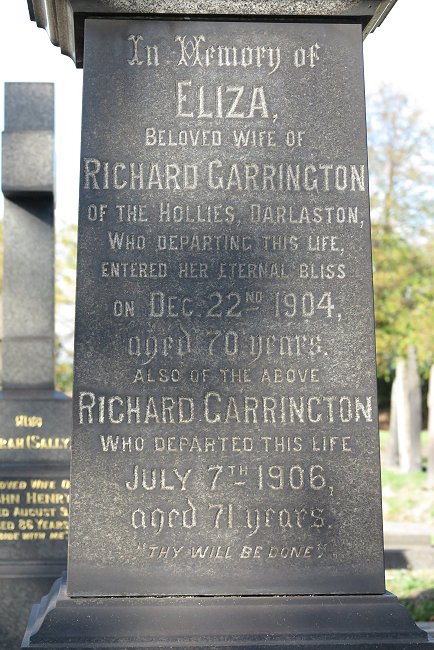

Richard died on 7th July, 1906, as can be seen in

announcement below. |

|

When the two brothers retired, Richard's son

Bertram became the senior partner, and in 1912 the

company was sold to local nut and bolt maker F.W. Cotterill. By this time the company produced

forgings for the automobile, agricultural, aircraft,

tube making, and electrical industries. |

| The inscriptions on the grave are as

follows: In memory of Eliza beloved wife

of Richard Garrington of The Hollies,

Darlaston who departing this life entered

her eternal bliss on December 22nd 1904 aged

70 years.

Also of the above Richard Garrington who

departed this life July 7th 1906 aged 71

years.

In loving memory of Catherine Jane

beloved daughter of Richard and Eliza

Garrington who departed this life December

13th 1905 aged 35 years. |

Richard Garrington's

grave at James Bridge Cemetery. |

|

A close up view of the

grave. |

|

The other inscription on

the grave. |

| In 1919 the company was purchased by G.K.N. and

soon experienced problems due to lack of orders in

the 1920s slump. Things didn't improve until the mid

1930s when orders poured in from the expanding motor

manufacturing industry.

In order to cope with the

large number of orders, the works were extended at a

cost of around £100,000. Extra stamping machines

were installed along with a heat treatment plant and

a new warehouse. The work was completed in the

summer of 1939.

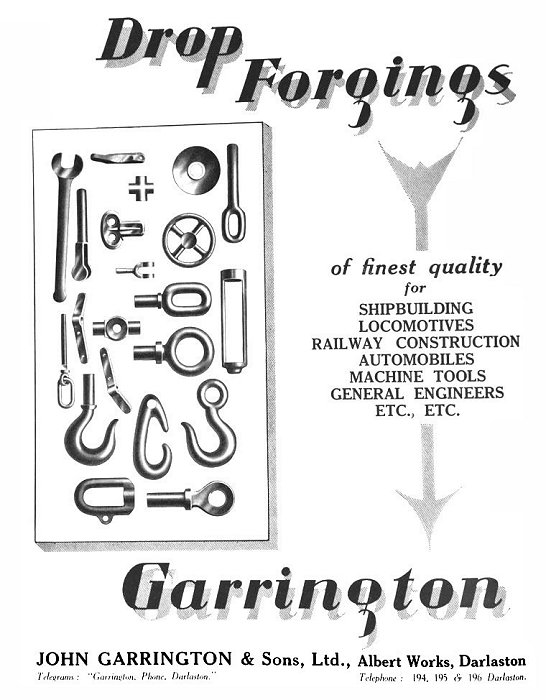

At the time the company produced drop forgings for

aircraft, ships, locomotives, railway construction,

vehicles, machine tools, and general engineering, in

carbon and alloy steels, and other metals. Garringtons

also specialised in heat treatment.

At this time G.K.N. considered

selling a majority interest in Garringtons to John

Harper Bean, the Tipton based car manufacturer.

|

|

An advert from 1926.

An advert from 1932.

| At the outbreak of World War II the company's

commercial activities were closely regulated by the

Government and so the scheme was dropped. G.K.N.

however, still wanted Bean's business expertise and

so the company purchased five thousand 5 shilling

ordinary shares in Beans Industries for £30,000 on

the understanding that John Bean would manage

Garringtons for four years from 1st January, 1940. In July 1940 a shell forging plant was built at

the works by the Admiralty at a cost of around

£100,000 to produce shells for the armed forces.

£261,433 was also spent on hammers, presses and

other plant by the Government. Also during the year,

Company Director and General Manager, Albert Beech

retired and was succeeded by Raymond P. Brookes and

J. C. Beech who were joint general managers.

|

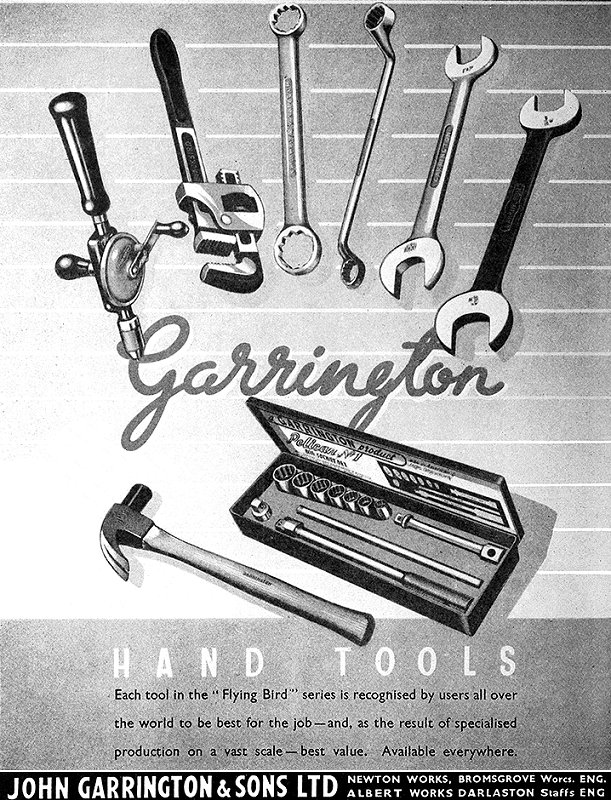

An advert from 1949.

An advert from 1955.

An advert from 1965.

| In 1944 G.K.N. negotiated with the Ministry of

Supply to purchase the machinery and plant installed

by the Government for £104,573 and to purchase the

building erected by the Admiralty for £40,000.

Adjacent land belonging to Tildsleys was also

purchased to provide space for expansion and

despatch facilities. New Massey hammers were

installed to replace the older machinery and

attempts were made by G.K.N. to sell the enlarged

and improved works, but there were no potential

buyers. The decision was then taken to keep the

company, and with this in mind John Bean was offered

a directorship of G.K.N. and the company entered one

of its most expansive and successful periods. |

| They produced all kinds of stampings at the large

factory that grew on the site. Over 100,000 tons

were produced annually for aircraft, shipbuilding,

railways, agricultural implements, mining equipment,

and road vehicles.

When the factory was in operation Willenhall Road

would vibrate as the large stamping machines operated.

The thumping noise from the machines could be heard some

distance away. People living in the nearby houses got so

used to this that they felt very uncomfortable during

the summer break when the works closed for a fortnight.

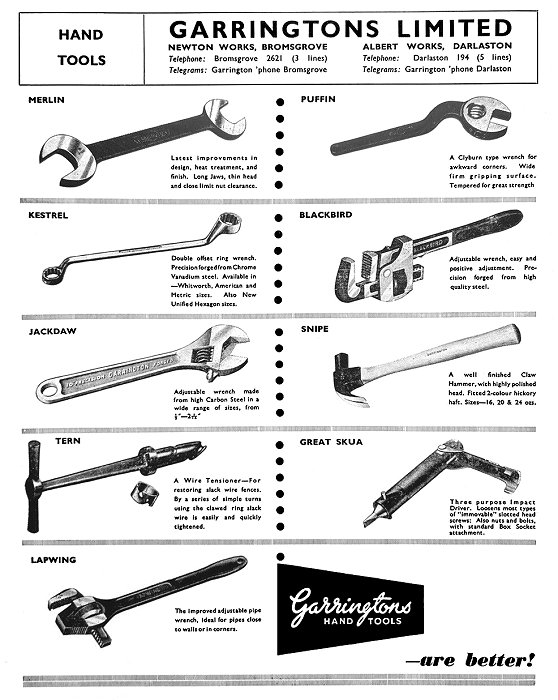

In 1946 Garringtons acquired Deritend Stamping

Limited of Newton Works, Bromsgrove in order to

expand production of castings for the automotive

industry. Newton Works eventually covered 50 acres,

and gave employment to 3,100 people. Garringtons

also specialised in a wide range of hand tools,

which were sold under many trade names including

'Raven', and 'Robin' (hand drills), 'Ball Pein',

'Curlew', and 'Adze Eye' (hammers), '11 Adjustable',

'Blackbird', 'Lapwing', 'Puffin', and 'Grebe'

(adjustable spanners), 'Jay', 'Magpie', 'Merlin',

and 'Kestrel' (spanners). |

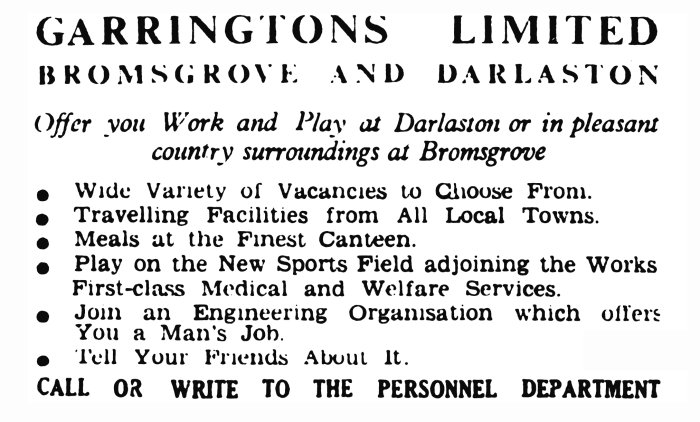

An advert from the mid 1950s.

Courtesy of Christine and John Ashmore. |

|

Another advert from the mid

1950s. |

|

Garringtons around

the time of closure. From the Howard

Madeley collection. |

A once familiar

sight, Garringtons' factory, as seen from

Willenhall Road. From the Howard Madeley

collection. |

An advert from the early

1950s.

A 4 inch 'Jackdaw' adjustable

spanner.

The other side of the 4 inch

'Jackdaw' adjustable spanner.

The Darlaston factory closed during the recession

of the late 1970s and early 1980s. The Bromsgrove

factory was acquired by United Engineering Forgings,

and closed in March 2002. The site was sold for

residential housing and industrial units.

Albert Works in the late

1990s.

All that remains of Albert

works, now a car park. |

|

Return to

the

previous page |

|