| A once common sound in the Black Country was the

relentless 'thud, thud, thud' of the drop hammer, which

produced a wide range of products that were formed in a die,

beneath the hammer. Drop forging or stamping as it was

known, became a practicality thanks to James Nasmyth's steam

hammer, that was developed in the late 1830s and patented in

1840. Prior to this, manufacturers relied on the smith's

anvil, and the water-powered, and later steam-powered tilt

hammer, which was less powerful than Nasmyth's device. |

|

An advert from 1894. |

In

Kelly's Staffordshire Directory of 1896, John Golcher is

listed as a gun lock maker & general stamper,

in Bright Street, King's Hill. The same entry appears in

the 1904 edition. In Kelly's 1912 Staffordshire Directory

the business is listed as: John Golcher, general stamper, Bright

Street,

King's Hill.

The entry in the 1914 edition of Bennett's Business

Directory is very different: Golcher J, iron and steel

merchant, Bright Street, King's Hill.

On 23rd February, 1917 the business became a private

limited company, trading under the name of John Golcher Limited.

The firm produced stampings of all kinds for many

industries. In the late 1940s and the 1950s, two of their

customers were Ford, and Rolls Royce. |

|

An advert from 1897. |

|

An advert from 1918. |

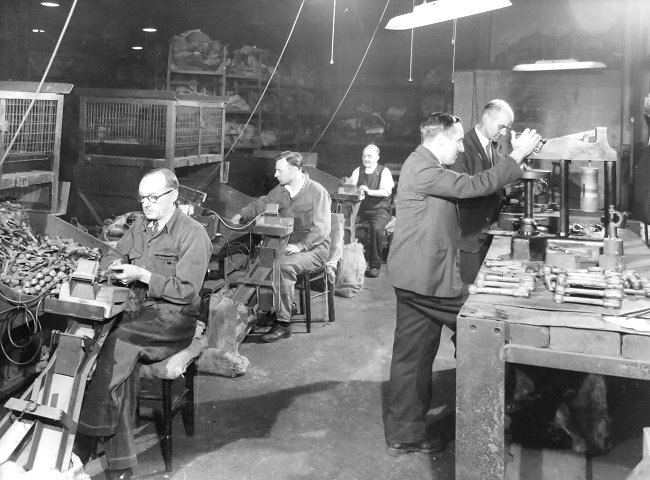

| The following photographs, taken inside the factory, are

courtesy of Sylvia Peters, one of my cousins. Her father, Ben

Platt, was a manager at the factory, and worked there for

many years. |

|

A stamper at work under the

hammer. The hot bar would have been held above the die while

the hammer dropped, and pressed the hot metal into the die

to stamp out the required shape. |

Chiselling-out a die by hand.

A very skilled job. |

|

|

Dies had to be frequently

replaced, and so they were copied from a master, in the

machine opposite. |

|

Milling and die copying machines

in operation. |

|

Another corner of the factory. |

|

A final interior view of the

factory. |

|

Return to

the

previous page |

|