|

E. C. &

J. Keay Limited was founded in 1879 at New Street,

Birmingham by Ernest Charles Keay and his brother James

Keay. They were builders and ironmongers. In 1884 they

moved to Cyclops Works, West Bromwich and began to

manufacture fencing, fittings, and steel fabrications.

The site that would eventually be occupied by the

company at James Bridge, originally belonged to Samuel

Mills, the wealthy industrialist and land owner who ran

Bills and Mills ironworks at The Green. After his death

in 1864 much of his land was sold-off by his executors,

Richard Mills, Martha Mills, and James Slater.

In January 1870, just over an acre

of land alongside James Bridge Railway Station and

Walsall Road was purchased for £150 from the executors

by Simeon Carter, who three years later formed his own

firm, Carter, Ford & Company Limited, manufacturers of

wrought-iron bridges, girders, roofing, railway

ironwork, and cab axles etc. The firm opened James

Bridge Ironworks on the site, but only had a relatively

short life, going into liquidation in September 1886.

|

A Keay builder's plate.

|

In December of that year, the company's property and

assets were put up for sale, and in January 1887 were

acquired by the Keay brothers.

In 1887 Keays moved to

"Bridge Yard", as they called the James Bridge site, and

in June 1888 they purchased an adjacent three acres of

land from Martha Mills and James Slater, along with a

strip of land on the opposite side of Heath Road.

Originally there were no buildings, only open gantries.

E. C. & J. Keay was

incorporated in 1893, and listed in the 1896/1897 Peck's

Trades Directory of Birmingham as makers of steam

boilers. By 1898 the whole business had moved to James

Bridge, and within twelve months the firm added an iron foundry

to the site for the production of bearings and cast

ironwork.

The firm produced many products over the

years, eventually specialising in structural steelwork

for all types of buildings, such as schools, hospitals,

factories, offices, and warehouses. Bridge Yard had three large

open shops, and good access to the railway, nearby

ironworks and rolling mills. |

|

Machines included saws, angle

croppers, punches, shears, guillotines, presses,

planers, drilling machines, bending rolls, riveting

machines, and welding machines. In fact everything

needed for the production of structural steelwork. There

were facilities for the trial erection of complicated

structures, and ample storage space for finished

materials so that deliveries of steel could be phased to

suit erection.

For erection purposes there were

electric scotch derricks, hand cranes, derricks and

winches, mobile cranes, and electric compressors to

provide power on site. Keays undertook the complete

design, fabrication and erection of their structures.

|

One of the firm's many jobs

before the First World War was the structural steelwork

for the dome of the Victoria and Albert Museum, seen

here at the factory in 1905. Courtesy of Wendy Marston. |

An advert from 1912.

An advert from 1912.

|

Mr.

James Keay's obituary in the Birmingham

Post, 14th December, 1920. Courtesy of

Peter J. Carter.

The death took

place suddenly at his residence, The

Cedars, Great Barr, on Sunday, of Mr.

James Keay, a director of the firm of

Messrs. E. C. and J. Keay Limited,

bridge builders and engineers of

Darlaston, Birmingham, and London.

Mr. Keay, who was

68 years of age, was also concerned with

other commercial interests in the

Midlands, being a director of Messrs.

Thomas Perry and Company, engineers of

Bilston, and of the Cannock and Leacroft

Colliery Company. A member of the Perry

Barr District Council, he at one time

held the position as chairman of that

body, and he was a member of the

committee of the Orthopaedic Hospital.

Mr. Keay took a keen interest in matters

relating to church life, being a member

of the Catholic Council and also

associating himself with the Bishop of

Birmingham Fund. |

|

| Mr. Ernest Charles Keay's

obituary in the Birmingham Post, 18th

April, 1932. Courtesy of Peter J.

Carter. Mr.

E. C. Keay, a leading figure in Midland

industrial and financial circles, died

this morning at his residence, 28

Westfield Road, Edgbaston. Mr. Keay, who

was in his 80th year, had been confined

to bed for about two weeks, following a

recurrence of an illness which

incapacitated him about twelve months

ago.

Mr. Keay was the

son of a former South Staffordshire

ironmaster, James Keay. He was educated

at Leamington and spent his early years

at Great Barr, where his father lived.

When still in his teens, the

responsibility of taking charge of a by

no means inconsiderable business at West

Bromwich fell on his shoulders. Rapidly

maturing however, the young man quickly

developed his business instincts and

extended the activities of the firm to

Darlaston, where he went into

partnership with his elder brother, the

late Mr. James Keay. There the two

brothers acquired the works of Carter,

Ford and Company and developed the

branch of constructional steelwork with

which the firm of E. C. and J. Keay

Limited is so closely concerned.

Important Contract

From its beginnings

the firm was responsible for a number of

large and important contracts including

the roofing of London rail termini, dock

sheds in Liverpool, South Wales and

Portsmouth, and the roofing of

electricity generating stations at

Greenwich for the L.C.C., besides

similar work on many buildings in

Birmingham and district. Still more

important, the firm increased its bridge

building enterprises, and in this

connection again was responsible for

many big contracts, both locally, in

various parts of the country and abroad.

Mr. Keay’s firm erected the first cast

iron bridge-building enterprises, and in

this connection was responsible for many

big contracts both locally, in various

parts of the country and abroad. In more

recent times its activities have

included the new G.W.R. station at Snow

Hill, the Queen’s Hotel, Birmingham, and

the steel constructional contract for

part of the great County Hall at

Westminster, London.

Tact

and Courtesy

While the extent of

Mr. Keay’s undertakings sufficiently

demonstrated his capacity as a leader of

industry, his personal attributes won

him the unqualified regard of those who

knew him at close quarters. He was

appraised as a man of undeniable tact

and courtesy both socially and in

business circles, a man who inspired his

staff with a genuine loyalty and ease of

impartial judgement and rigorous

sincerity. Besides being the chairman of

E. C. and J. Keay Limited, he was a

director of the South Staffordshire

Waterworks Company, of the Loddington

Ironstone Company, of the New Cransley

Iron and Steel Company Limited, and had

been a director of C. Akrill and Company

Limited of West Bromwich, Thomas Perry

and Son Limited of Bilston, and local

director of Barclays Bank. Absorbed

largely in business affairs, he had

little time to spare for public work,

although he was a Justice of the Peace

for Staffordshire for 30 years.

Work

For Hospitals

Mr. Keay also

interested himself in the Birmingham

hospitals and a number of other local

charities, besides watching closely the

progress of the Cancer Research Fund. At

the Birmingham Children’s Hospital he

dedicated a bed to the memory of his son

James, who was killed in France in 1916.

He was a considerable subscriber to the

Birmingham Hospital Centre Scheme.

Mr. Keay’s wife

died in 1922, and he leaves two married

daughters and a son, Mr. Douglas Keay,

who is engaged in the business. The

funeral is on Tuesday, when a service

will be held at St. Augustine’s Church,

Edgbaston before the interment at

Quinton. |

|

| In 1926 the company went into voluntary

liquidation and was reformed as E. C. & J. Keay

(1926) Limited. |

Keays provided the structural

steelwork for the Midland Counties Dairy on the corner

of Lea Road, Wolverhampton. Built in 1930/31. |

| In 1935 the company was wound-up and reformed as

a private limited company: E. C. & J. Keay Limited. |

|

An advert from 1963. |

|

The firm provided the steelwork for Birmingham Snow

Hill railway station, which consisted of 6,000 tons of

steel, transported to the site on the firm's Pollen

railway girder wagons. Keays also supplied 1,000 tons of

steelwork for Leicester railway station, the cast iron

pillars used in Kensington High Street Underground

Station, and the steelwork for Neachells No.1 and No.2

power stations, the latter using 8,000 tons of steel.

|

| Other contracts included the Great

Western Hotel at Paddington; Llandudno Railway

Station; large sheds at Southampton Docks; the first

aeroplane hanger at Elmdon; Walsall Technical College;

Typhoo Tea Buildings and Warehouse; Offices at

Birmingham; Midland Counties Dairy at Wolverhampton;

and McKechnie Brothers factory at Aldridge. The firm built many bridges

including Norfolk Bridge at Shoreham-by-Sea; hoppers;

bunkers; railway signalling equipment; the fencing and

gates for Willenhall Memorial Park; also bus depots; and

carried out riveted platework, and welded fabrications.

Structural steelwork was also supplied for building

projects abroad.

The gates and fencing at

Willenhall Memorial Park.

In 1957 Keays became a subsidiary

of N. Hingley and Sons, Limited, and in November 1960,

part of the Lloyds Group. On 12th August 1969 F. H.

Lloyds became part of F. H. Lloyd Holdings Limited.

In 1972 the Directors decided to

restructure the company to bring about more effective

coordination of marketing programmes, production

techniques, research technology, and to improve

inter-company communications. In order to achieve this

the companies were grouped into three divisions;

engineering, foundry, and steel. The restructuring was

announced in December 1972 by Mr. M. C. Lloyd. Keays

became part of the Engineering Division. |

Keay's 'Hydrocon Highlander' 6 ton mobile

crane, acquired in 1962.

Keay's 'Hydrocon Highlander' 6 ton mobile

crane, acquired in 1962.

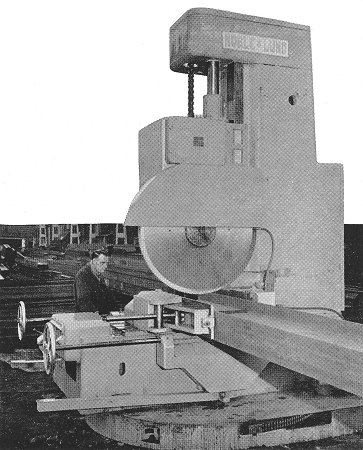

| 1962 saw the installation of a

54 inch Noble and Lund vertical cold circular sawing

machine, which could cope with the largest sections of

the company's new universal beam range.

It could vertically cut steel

joists of up to 40 inches by 18 inches, at any angle. |

|

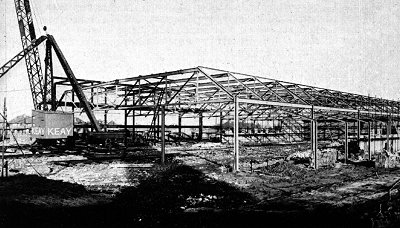

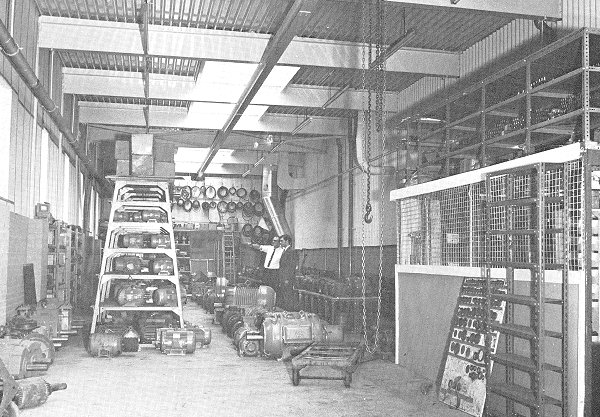

In 1971 Keays designed and built

the new 3,600 square feet storage bay and works canteen

for fellow Lloyds Group member, The Mechanical &

Electrical Engineering Company (Walsall) Limited. |

|

|

|

| A small,

but relatively complex installation took place

in 1971 at George Johnson & Company (Birmingham)

Limited in Shirley. The new building had to be

erected over the top of an existing building

that had to remain in use during the building

work, in order to maintain production. When the

new building had been completed, as seen on the

right, the existing building was demolished.

|

|

|

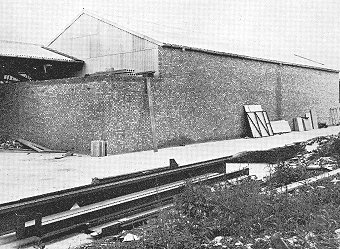

The erection of a two-bay

warehouse at Wednesbury in 1971 for Brinton, Adams &

Richards Limited. |

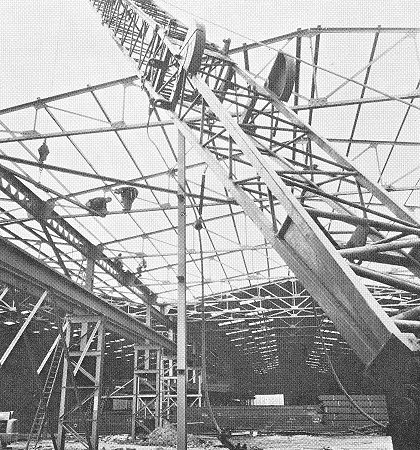

| Another view of the warehouse

during construction. |

|

The old office building in

Station Street Darlaston, which was demolished in

1973. Courtesy of Wendy Marston. |

|

The new main office building

in Station Street, built in 1973 following the

demolition of the old offices. Courtesy of Wendy Marston. |

|

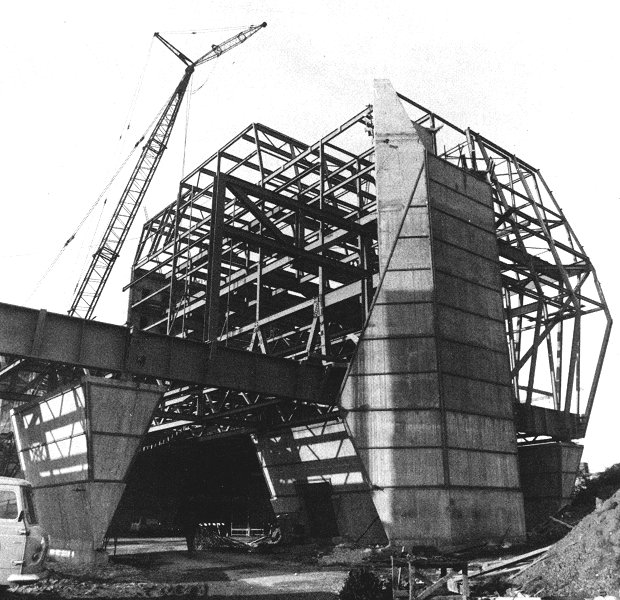

Another Keay project, the

steelwork for the Coventry sports complex building.

A contract worth £185,000.

Courtesy of Wendy Marston. |

|

Some of Keay’s projects in the

1970s included the building of the steelwork for a

number of Littlewoods stores, including ones at

Norwich, Harrow, Lewisham, Truro, West Bromwich,

Worcester, Kidderminster and Corby. Other projects

include steelwork for the following:

The Incinerator

Building at City of Stoke-on-Trent.

A number of 200

ft. high flare towers for North Sea oil rigs.

Manchester

United Football Club including some large Cantilever

girders.

A continuous

casting platform for Round Oak Steelworks.

In 1975 the company installed a

computer to provide "instant designs" of portal

frame structures. A special program was written to enable Keays to increase their activities

in the supplying of supporting structures for water

tanks made by Brown Lenox (London). |

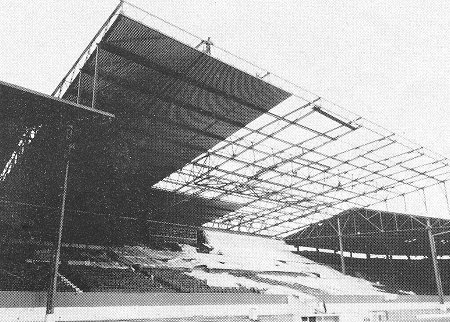

| In 1975 Keays built a new roof

covering one of the stands at Manchester United's football

ground, Trafford Park. It involved nine 160 ft. long lattice

girders, each weighing nine tons. |

|

|

In 1977 a reorganisation scheme

began at James Bridge to create larger production

areas, improve the overall efficiency of the plant,

and provide better working conditions. As a result,

Keay’s factory ceased to be used for structural

steelwork, and became Lloyd’s Pattern Shop. |

|

Return to

the

previous page |

|