| The Platt family moved to Wednesbury from Shropshire

in about 1790. Samuel Platt, born around 1780, started a

business at King's Hill, which grew into a large

foundry, with a large number of staff. He married Mary

Elizabeth Wilkes. By the 1880s

Kings Hill Foundry was producing a range of machines,

many of which were aimed at the local nut and bolt, and

tube manufacturers. Samuel Platt junior, was born in

1813 and christened on 31st January, 1813 at St.

Lawrence's Church, Darlaston. He married

Susannah Deeley Howl, then around 1842 married his

second wife, Rose

Hannah Hadley, who was born in 1819. In 1841 he was

employed as a Pattern Maker, in West Bromwich.

In the 1831 and 1851 editions of William White's

History, Gazetteer, and Directory of Staffordshire, the

business is listed as Samuel Platt, model maker (meaning

pattern maker), King's

Hill, but in the 1861 edition of Jones's Mercantile

Directory of the District of South Staffordshire and

East Worcestershire, it is listed as Samuel Platt, brass

founder and iron founder, King's Hill.

In the 1851 census, Samuel Platt

senior's family is listed as living at 103 Darlaston

Road, King's Hill. The entry is as follows:

Samuel Platt, aged 71, pattern

maker. Born in Drayton, Shropshire (Market

Drayton).

Mary Platt, Wife, aged 67. Born

in Darlaston.

Matilda Platt, Daughter, age

30,

unmarried. Born in Wednesbury.

John Platt, Son, age 28,

unmarried, pattern maker. Born in Wednesbury.

Mary Platt, Daughter, age

25,

unmarried. Born in Wednesbury. |

In the 1871 census, the entry for

Samuel Platt and his family, who lived at 119 Darlaston

Road, King's Hill, is as follows:

Samuel Platt, aged 58, brass and

iron founder, employing 26 men & 5 boys.

Born in Wednesbury.

Rose Hannah Platt, Wife, aged 52.

Born in Wednesbury.

John Platt, Son, aged 27, unmarred,

iron moulder. Born in Wednesbury.

Eliza Platt, Daughter, age 21,

unmarried. Born in Wednesbury.

Thomas Platt, Son, age 18,

unmarried, iron moulder. Born in Wednesbury.

Frederick Platt, Son age 13,

unmarried, iron moulder. Born in Wednesbury.

Isaiah Platt, Son, age 11, unmarried,

scholar. Born in Wednesbury. |

The firm displayed machines at the Wolverhampton

and Staffordshire Industrial and Art Exhibition, which

ran from 30th May until the end of October 1884. The

following, is a description of the firm's exhibit from

'The Engineer', 13th June, 1884:

|

Among a varied

assortment of machinery connected

with the nut and bolt and tube

manufacture, Mr. Samuel Platt,

engineer, of King's Hill Foundry,

Wednesbury, has a specially designed

noiseless bolt screwing machine

which deserves to be known outside

the local nut and bolt centres, to

which at present its use is chiefly

confined. It is a three pulley

machine, driven by two bands, one

straight and one crossed, and is

reversed by raising the lower end of

a cross lever. The reversing gear is

kept in its place by a ball on the

hanging lever. The reversing motion

is accomplished without strain or

noise. It manipulates bolts and nuts

together.

Another machine

by the same exhibitor which has

found favour in New Zealand and New

South Wales for artesian well

purposes is a specially designed

improved revolving cutter, which can

be worked by hand or by power, and

will cut off any sized tube from ⅛

in. to 4 in. It will also treat

small round iron, brass, or copper.

The weight is 1 cwt. 3 qr. 18 lb. |

|

|

|

King's Hill Foundry in the mid

1880s. At this time there were many small buildings on the

site, with some houses and shops along Darlaston Road.

At this time the business was very

successful and so the factory would soon be enlarged to

cover the whole site, including the green area along the

southern edge of the site. |

The entry for the family in the 1881 census, still

living at Hawthorn Cottage, 119 Darlaston Road, is as follows:

Samuel Platt, aged 68, engineer and

iron founder, employing 28 men & 12 boys. Born

in Wednesbury.

Rose Hannah Platt, Wife, aged 62. Born in

Wednesbury.

Eliza Platt, Daughter, age 30,

unmarried. Born in Birmingham (different to

previous census).

Isaiah Platt, Son, age 21, unmarried,

clerk in foundry and fitter. Born in Wednesbury.

Louisa Hall, general domestic servant,

age 17. |

|

|

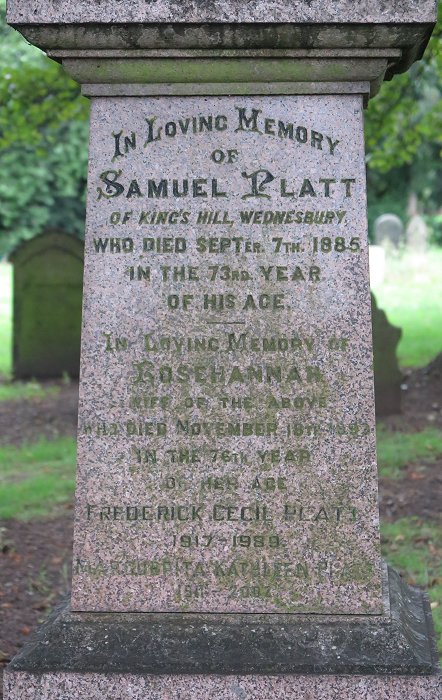

Samuel Platt's grave in Wood Green

Cemetery, Wednesbury. |

| The inscriptions on the grave are as follows:

Front:

In Loving Memory of Samuel Platt of King's Hill

Wednesbury, who died September 7th, 1885. In the 73rd

year of his age.

In Loving Memory of Rosehannah, wife of the above who

died November 18th, 1893 in the 76th year of her age.

Frederick Cecil Platt, 1917 - 1989.

Marguerita Kathleen Platt, 1911 - 2002.

___________

Left hand side:

In Loving Memory of Hannah the beloved wife of Tom Platt

of Rosslyn, Goldthorn Hill, Wolverhampton who died

October 15th, 1902 in the 51st year of her age.

In Loving Memory of the above named Tom Platt who

died December 26th, 1904 in his 54th year.

In Loving Memory of Gertrude, wife of George Platt,

F.R.G.S. Passed away June 30th, 1925 in her 85th year.

___________

Back:

In Loving Memory of Norris, son of Tom and Hannah Platt

who died September 2nd, 1936 aged 51 years. |

The inscription on the front of

the memorial. |

The inscription on the right hand side reads as

follows:

In Loving Memory of Nancy the wife of Fred Platt. Born

July 24th, 1886. Died August 28th, 1911.An

affectionate remembrance of Ralph Frederick, husband of

Ethel Mary Platt. Born 2nd May, 1881. Died 10th October,

1944. |

| King's Hill Foundry in 1904.

During the previous twenty years the

factory had been greatly extended and now covered the whole

site.

The frontage remained much the same

until the 1970s. |

|

|

A photograph from an old postcard

showing the last steam tram that operated from Darlaston

depot on 15th June, 1904. It's on its way to Darlaston from

Walsall via the Pleck and Wednesbury, passing King's Hill

Foundry.

The frontage remained much the same

until the factory closed. Only the far single storey

building would change to any great extent. |

| Samuel died on 7th September, 1885 and is buried at

Wood Green Cemetery. The business was then run by seven

family members, in partnership, until 1894, as can be

seen below: |

|

The family's entry in the 1891 census

is as follows.

Address: Hawthorn Cottage, Darlaston

Road, King's Hill.

Rose Hannah Platt, Widow, aged 72. Born in

Wednesbury.

Eliza Platt, Daughter, age 41,

unmarried. Born in Birmingham.

George Platt, Son, age 33, unmarried,

fitter. Born in Wednesbury.

Isaiah Platt, Son, age 30, unmarried,

pattern maker. Born in Wednesbury. |

Rose Hannah Platt died on 18th

November, 1893.

Other family entries in the 1891 census

are as follows:

Address: 118 Bright Street, King's

Hill.

John Platt, aged 45, iron founder. Born in

Wednesbury.

Rose Platt, Wife, aged 40. Born in

Wednesbury.

George Platt, Son, age 18,

unmarried, iron moulder. Born in Wednesbury.

Margaret Platt, Daughter, age 15,

unmarried. Born in Wednesbury.

Frederick Platt, Son age 8, unmarried,

scholar. Born in Wednesbury. |

| Address: 119 Darlaston Road, King's

Hill. Tom Platt, aged 38, foreman

moulder. Born in Wednesbury.

Hannah Platt, Wife, aged 38. Born in

Darlaston.

James W. Platt, Son, aged 16. Born in

Wednesbury.

Tom Platt, Son, age 13. Born in

Wednesbury.

Fred Platt, Son age 11. Born in

Wednesbury.

Rose Hannah Platt, Daughter, age 8. Born

in Wednesbury.

Isaiah Platt, Son, aged 7. Born in

Wednesbury.

Norris Platt, Son, aged 5. Born in

Wednesbury.

Eliza. Platt, Daughter, aged 4. Born in

Wednesbury.

Ernest Platt, Son, age 2. Born in

Wednesbury.

Samuel Platt, Son age 5 months. Born in

Wednesbury.

Emma Pallat, general domestic servant,

age 22. Born in Darlaston. |

Entries in the 1901 census:

Address: Church Hill, Wednesbury.

John Platt, aged 55, iron founder and

employer. Born in Wednesbury.

Rose Platt, Wife, aged 50. Born in

Wednesbury.

George Platt, Son, age 28, unmarried,

merchant's clerk. Born in Wednesbury.

Emmie Ellis, general domestic servant,

age 23. Born in Tipton. |

Address: Hawthorn Cottage, King's

Hill.

Eliza Platt, aged 50, head, unmarried,

engineer, iron founder and employer. Born in

Birmingham

Isaiah Platt, Brother, aged 40,

unmarried, engineer, iron founder and

employer. Born in Wednesbury.

Elizabeth Robinson, general domestic

servant, age 27. Born in Wednesbury. |

By 1886 Isaiah became head of the

drawing office, and then a partner. In 1918 he left to

form his own business, Isaiah Platt of Wednesbury. Two

other family members, John Platt and George Platt left

the business on 31st August, 1904, as can be seen below

(from the London Gazette):

|

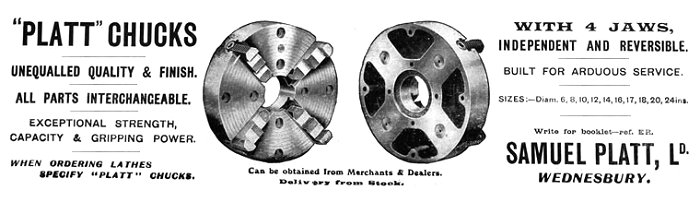

| In the 1904 edition of Kelly's Staffordshire Directory,

Frederick Platt is listed as living at The Shrubbery, Wood

Green Road, Wednesbury, and the business is still listed as

Samuel Platt, Brass & Iron Founder. In the 1909 Ryder's

Annual the business is advertised as Samuel Platt Limited.

By this time the firm was producing a wide range of

products including machinery for tube making,

nut and bolt making, drop hammers, stripping

presses, reeling and straightening, and also lathe chucks,

pulleys, mill gearing, shafting, shaft fittings,

and pressings.

The firm also patented designs for a wide range of

machines, for many applications. |

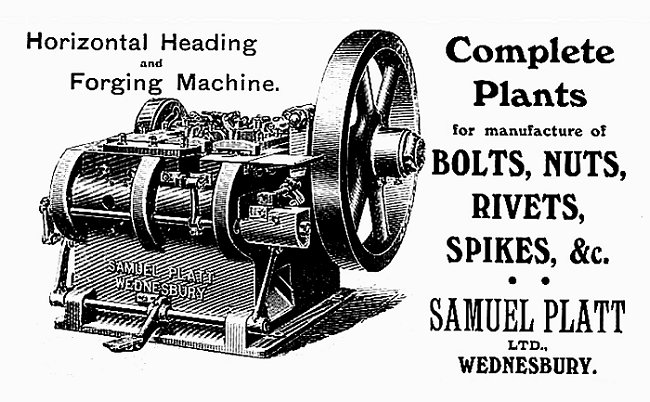

An advert from 1909. |

An advert from the 'Engineering Journal' 1909.

From 'Engineering' 24th November, 1899.

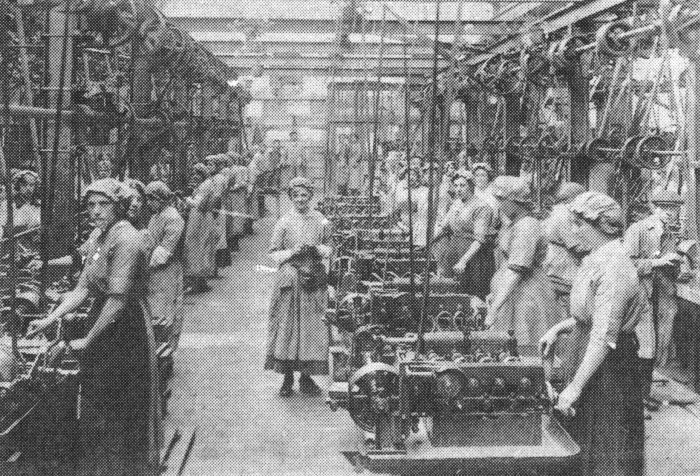

Male members of staff during the First World

War.

The production of munitions in the First World

War.

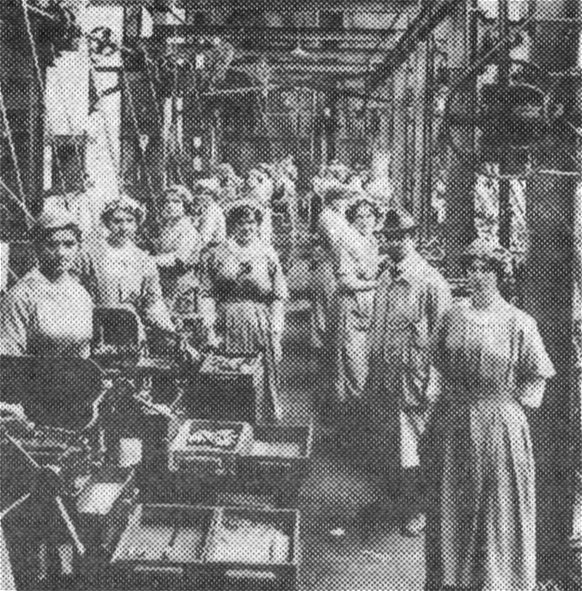

The bullet production line in the First World

War.

An advert from 1921.

An advert from 1909.

King's Hill Foundry.

From the collection of the late Howard Madeley.

From the 1918 Wednesbury Handbook.

An advert from 1924.

| In 1945 the company was voluntarily wound-up and

reconstructed, as can be seen below: |

| In 1959 the business was acquired by Harper Engineering

and Electronics, and in 1965 it became part of Cope Allman & Company.

In 1981 Samuel Platt Limited was wound-up: |

|

Some of the company’s patents:

| 6th October, 1926 |

Substitutes for packing

non-metallic stuffing-boxes. By Ralph Frederick Platt. |

| 7th December, 1926 |

Metalworking presses. By George Arthur Standley and Samuel Platt. |

| 15th September, 1927 |

Improvements relating to machinery bearings.

By Ralph Frederick Platt. |

| 1st March, 1928 |

Improvements relating to presses. By George

Arthur Standley and Samuel Platt. |

| 26th March, 1928 |

A machine for coating fabrics and like

materials in long lengths by applying an

adhesive and then dusting or sifting powdered

cotton, wool, etc. in various colours. By Downham & Company (1927), Limited and Samuel Platt. |

| 26th September,

1929 |

Improvements in or relating to machines for

surfacing fabrics and like materials in long

lengths. By John Downham & Company and Samuel Platt. |

| 3rd November,

1932 |

Stuffing box substitutes. By Ralph Frederick

Platt. |

| 26th April, 1934 |

Improvements relating to machinery bearings.

By Ralph Frederick Platt. |

| 16th August,

1961 |

A machine for straightening bars or tubes of

the kind incorporating a pair of rolls. |

| 31st October,

1962 |

Improvements in, or relating to

straightening machines. By Arthur Martin Garrington. |

| 14th May, 1963 |

Friction drop hammers. |

| 27th May, 1964 |

A new or improved drop hammer or like

machine. By Arthur Martin Garrington. |

| 19th May, 1965 |

A machine for straightening bars and tubes

by rolling. |

| 13th July, 1966 |

Machines for straightening bars and tubes by

rolling. By Graham Roy Martin. |

| 19th April, 1967 |

Reflector assembly for roads. By Martin

Graham Roy. |

| 6th December,

1967 |

Apparatus for feeding rods or tubes for

drawing dies. |

| 5th March, 1969 |

Feeding apparatus for use with a drawbench. |

|

A five-throw reducing and forging machine from

1909.

An advert from 1909.

| Articles from 'The

Engineer' magazine: |

|

The Engineer. 9th May, 1890. Platt’s Bolt and Rivet

Forging Machine.

The above engraving illustrates

a double bolt and rivet forging machine, made by Mr.

S. Platt, Wednesbury. These machines are simple in

construction and the tools not expensive. The bottom

tool, or die, is of cast iron, and only requires

drilling out for the different sizes of bolts to be

made. The top tool, or snap, is of wrought iron

faced with steel. The flywheel is held on a

taper-turned cone on the shaft, so that the flywheel

will slip in case of the stoppage of the machine by

any greater pressure than is ordinarily required.

The machine will make at one blow, either snap,

cheese, square, or hexagon head bolts or rivets, so

that these kinds the machine can be worked on all

four dies of the two ends at once.

The two sets of dies at either

end of the machine may be used for making bolts with

square necks, which obviates reheating or taking the

bolts to the other end of the machine, the bolt

being upset in one die and then removed to and

finished in the other. This is only when the square

neck is required. The machine will make bolts up to

16inches long. The saddles carrying the bottom tools

slide on planed steel plates let into the table of

the machine, so that they can be easily replaced

when worn.

In working the machine the bottom tools are drawn

back by the levers attached to the slides carrying

them, the iron heated at one end is inserted in the

die, and the die is then pushed under the top tool,

one blow of which for all kinds, except square neck

bolts, finishes the bolt. The die is then drawn

back, and whilst doing so a self-acting arrangement

raises the bolt that has been made, and it is then

picked out by a pair of tongs. It will be seen that

the machine is applicable for a great variety of

ordinary work. A fine jet of water should be

directed on to both top and bottom tools when the

machine is at work. |

|

|

The Engineer 9th December, 1892. Draw Benches

We illustrate by the engravings

above, two draw benches for the manufacture of cold

drawn seamless tubes. The lower bench, in which the

stands are all bolted to retaining plates, being for heavy work,

is especially strong in all its parts, and all the

joints throughout, including the retaining plates

and stands, being planed, makes the whole, when bolted together and bolted down

to its foundation plates, very rigid and firm, so

that the work can be done not only better, but

faster than on an inferior bench. The driving wheel being in the centre of

the bench instead of on one side allows the workmen

to pass to the extreme end of the bench on both

sides when drawing tubes, thus utilising the whole length of the bench, and being

able to draw on the one side a longer tube than if

the wheels were on the outside of the bench. It may

also be noted that the driving wheel being in the centre of the bench, the

power is more evenly transmitted, and with less

strain on the bench and the bearings than when the

wheel is on the outside.

The bench has a treble link

chain, and both the links and the rivets of the

chain are of steel, the links of the chain being

drilled and also milled on the ends by tools

specially constructed for this purpose.

The bodies of the wagons on the bench are also of

steel, and are carefully balanced so as to give a

minimum of labour to the workmen in catching and releasing the same from the

chain. The connecting bars and levers to the

throw-out gear are under the bench, and thus clear

from the foot of the workmen, and being carried to

the die plate on each side enables

the workmen to throw out the underground gear, and

so stop the bench when necessary.

The stems, mandrils, and dies,

as will be seen, are carried by the front end of the

bench. The upper bench, with the lattice supports,

is intended for lighter work than the preceding bench, and although not planed

on the joints is firmly bolted together, and the

chain, links, and rivets are of steel, and drilled

and machined as in the heavier bench, although not so strong in section and

not of treble links. The throwing out levers are

carried up to the die-plate on each side of the

bench, and the wheel is also in the centre of the

bench, as in the heavier one, and

either balanced wagons or pliers are made for

gripping the tubes, as preferred. These tube drawing

benches are made by Mr. S. Platt, of Wednesbury. |

|

|

An advert from 1921. |

|

The Engineer. 24th November, 1893. Four feet Ingot

Boring Machine.

We illustrate above an ingot

boring machine designed and made by Mr. Samuel

Platt, Wednesbury, for boring the solid ingots from

which the cold drawn seamless steel or copper tubes

are made, and for boring ingots up to 4ft. in

length. The self-centring grips for holding the

ingots are tightened on the ingots by screws worked

simultaneously by worm wheels and worms, and a band

wheel at the back end of the machine. In working the

machine there is a fast band traverse of the main

spindle for bringing the boring bit up to the ingot

before throwing into gear the self acting motion,

and by means of special self-acting arrangements the

machine can be set to throw out of action the

self-acting traversing motion, after having bored

any desired length of hole to which the machine may

be set, when the boring bit can be run back clear of

the ingot by the quick hand traverse. The machine

has two speeds in the self-acting traverse to suit

different diameters of holes to be bored. If desired

the machine can be fitted with geared wheels, and

will then bore up to 12in. diameter ingots. |

|

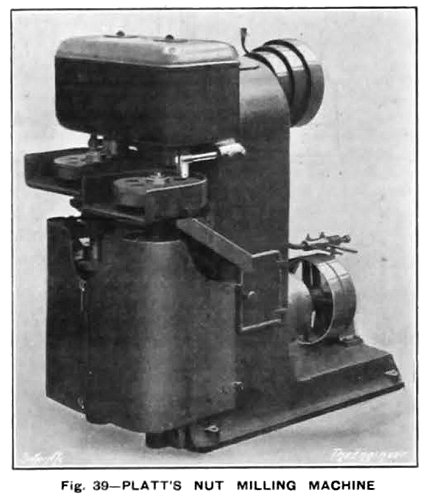

The Engineer. October 25th, 1912. An

extract from the article: Some of the exhibits at

the Engineering and Machines Exhibition at

Olympia.The production of nuts and bolts in

large quantities necessitates the employment of a

special plant. Such a plant is shown on the stand of

Samuel Platt, Limited, Wednesbury. Three of the machines

are illustrated herewith. The first, Fig. 39. is a

double spindle nut-milling machine for removing the pin

or burn from hot forged nuts. The machine has two

milling spindles, and is semi-automatic in operation.

|

The nuts are placed in chuck plates

on the revolving tables, which are raised vertically six

times per revolution, bringing the nuts under the

cutters, and after being operated on they are projected. One operator can, we are informed, feed both plates, and

an output of upwards of 20,000 nuts per day of 10 hours

is obtainable by a dexterous operator .

A wide range of

adjustment is provided to suit nuts of varying

thickness.

These machines are also made with a

single spindle. |

|

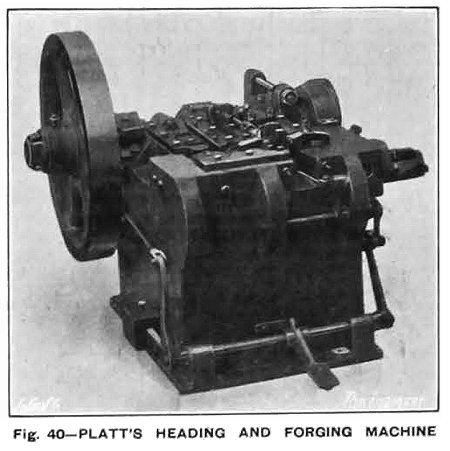

Fig. 40. represents a horizontal heading and forging machine

constructed on the lines of the well known large machine

made by the same firm for the rapid production of large

quantities of bolts, rivets, spikes, etc.

The machine

illustrated is specially designed for dealing with the

smaller sizes of bolts, etc., and forges a bolt head in

two blows, after which the bolt is cut off to length and

ejected.

It may, however, be used equally

well for making bolts or rivets in one blow, in which

case the article is forged, cut off from the heated bar,

and ejected at each stroke. |

|

|

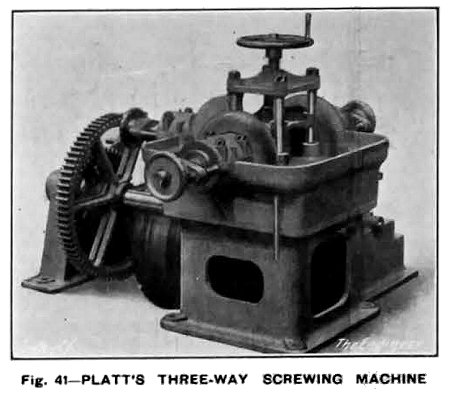

In tube machinery Messrs. Platt

show a three-way screwing machine, Fig. 41. for screwing

wrought iron or malleable iron gas, water, and conduit

fittings.

The fittings are held by twin grips

adjusted by a hand wheel, and are operated on

simultaneously by three screw taps. These are withdrawn

automatically after each operation.

The length of the taps

is also regulated by the hand wheel and the

guide- screw, which are made according to

the pitch of the thread being tapped, and

can readily be altered.

|

The machine is operated from a self-contained

countershaft, on which are three pulleys, one for

each direction of the spindles and a loose pulley.

This shaft communicates motion to a second shaft by

spur gearing, and the tapping motion is obtained by

bevel gearing on the second shaft.

The reversing motion is effected by means

of spur and worm gearing actuating a quadrant plate,

quadrant, and clutch with stops to suit the various

lengths of fitting. The machine on exhibition at Olympia

differs from that shown in our illustration somewhat in

that it is mounted on a large cast iron tray. The

machines in motion are driven by transmission plant of

the firm's own production, and the hangers are equipped

with Platt's swivelling self-oiling bearings.

|

|

|

Return to

the

previous page |

|