| Motor Panels (Coventry)

Limited |

|

Motor Panels (Coventry) Limited was

founded by Mr. A. S. Smith in July 1920 to produce motorcar

panels, mainly by hand. The firm acquired a small premises

in George Street, Coventry, which was soon outgrown. In the

early 1920s a larger premises was acquired in Holbrook Lane,

which became the company’s permanent home. A toolroom and

press shop were soon added, and the firm’s products became

known as ‘Smith’s Panels’.

In 1937 the factory was extended with

the addition of a large steel-framed building erected by

Rubery Owen’s Structural Department. Two years later another

large extension, also erected by Rubery Owen, was added to house a large press shop. The

new building covering 25,000 square feet would be fitted with the most up-to-date

machinery, overhead conveyors, an underground die park, and

subterranean machines for scrap collecting and bundling.

Although the building was soon completed, the plant was not

installed until after the Second World War.

In 1939 just before the outbreak of

war, the company went into voluntary liquidation, as can be

seen from the following entry in London Gazette on 7th

April, 1939:

|

|

On 3rd September, 1939 the company

began to concentrate on war work, all civilian orders were

cancelled. Items produced by the company during the war

included aircraft fuel tanks, track shields for Churchill

tanks, body panels for ‘Scout’ cars, sea mines, anti

submarine projectiles, tail planes for Stirling aircraft,

refrigerator containers, and trailers. In order to fulfil

the Ministry orders, the company increased its workforce to

around 1,000.

Although Coventry was heavily bombed in

the early 1940s, the factory suffered comparatively little

damage, but in 1942 a serious fire destroyed nearly one

third of the factory.

|

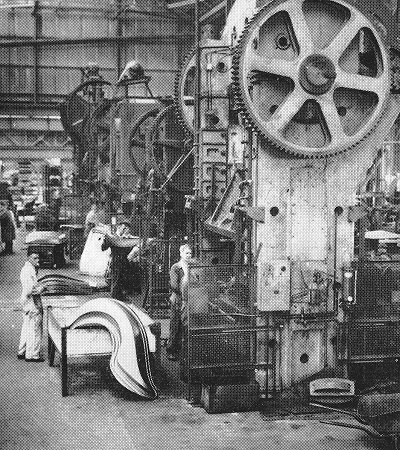

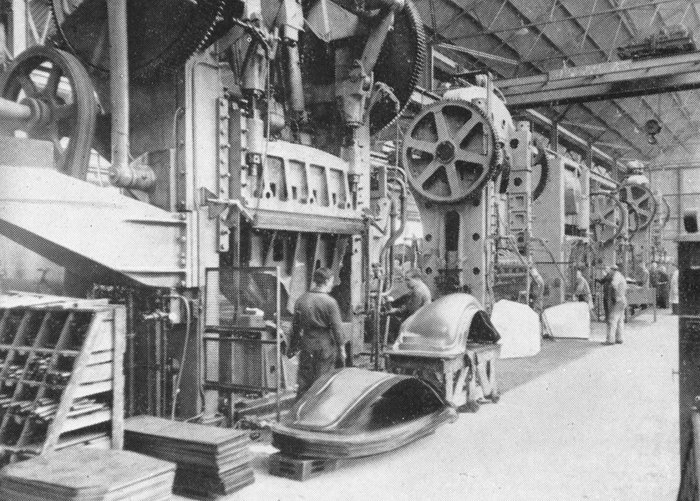

One of the firm's large presses.

From the autumn 1947 edition of the staff magazine

"Zeal". |

In April 1943 Motor Panels became a

member of the Owen Group, with Mr. P. J. Freeman as Managing

Director.

Through his efforts production greatly increased,

and many improvements were made in the factory. Sadly he

died in October 1944 and was greatly missed.

His successor,

James Milner Phillips, a brilliant automotive engineer

became famous in the 1960s when the Owen Organisation built

Donald Campbell’s record breaking Bluebird Proteus CN7 car.

Mr Phillips supervised the building and testing of the car,

and the record attempts in Australia. |

| After the war, the firm manufactured

body panels for many well known makes of car including

Jaguar, Armstrong Siddeley, Alvis, Daimler, Triumph, Austin,

and Wolseley, and also Morris vans.

The product range was

greatly extended to include kitchen and bathroom equipment,

metal clothes lockers, oil-fired electric radiators, dodgem

car bodies, and agricultural machinery.

It was hoped that

the wide product range would ensure that work would always

be available, so ensuring regular employment for the staff. |

James Milner Phillips. From the

autumn 1947 edition of the staff magazine "Zeal". |

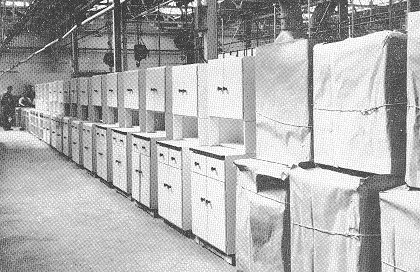

Kitchen units in production. From

the autumn 1947 edition of the staff magazine "Zeal". |

A well-equipped surgery was added,

under the supervision of a qualified nurse, and the Works

Benevolent Society provided financial aid for sick or

unfortunate employees.

The Social Club organised sports

and social activities for the staff, using facilities at

the sports ground at Britannia Works in Paynes Lane,

Coventry, owned by Henry Caton & Company (1936) Limited,

incorporated in October 1936.

It had also been taken over by the

Owen Group, and became Rubery Owen's Coventry Works.

|

|

Among the events organised by the

Social Club was the annual sports day when people

competed for the P. J. Freeman Memorial Cup, and various

inter-departmental trophies. There were amusements for

children, and fundraising activities for the Social

Club.

Sports activities included

football, table tennis, darts, and fishing, thanks to

the flourishing angling section.

All the employees were encouraged

to attend part-time courses at Coventry Technical

College, and were paid a bonus for passing exams.

|

Completed kitchen units awaiting

despatch. From the autumn 1947 edition of the staff

magazine "Zeal". |

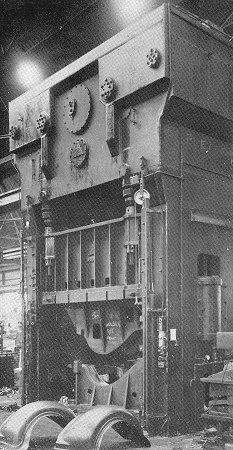

Another of the large presses. From

the summer 1950 edition of the staff magazine

"Goodwill". |

The factory was managed in a very modern way. There

were several committees which oversaw all aspects of

production and sales.

The Works Joint Management Committee which met every

three months, consisted of representatives from the

senior management team, and middle managers from every

department.

There were sub-committees, which met at least once a

month to sort out problems on the shop floor, and a

Supervisors' Discussion Group that met after work, once a week (once

a fortnight in the summer), attended by

members of management, all heads of department,

supervisors, and foremen.

Meetings included talks by specialists, film shows,

and the discussion of any problems in the factory.

All meetings were minuted, and copies of the minutes

were circulated to all departments discussed at a

meeting. In the 1970s, one of the firm's products was the

'Transcontinental' lorry cab. |

|

A corner of the press shop. |

|

Another view of the press

shop. |

|

By 1980 it became the cab design and

manufacturing subsidiary of Rubery Owen, about 25

percent of turnover was from the design and supply of cab

manufacturing facilities to overseas companies. In 1991 administrative receivers were called-in, and

in 1995 the business went into final liquidation. |

The tool section of the Joint

Production Committee. From the autumn 1947 edition of

the staff magazine "Zeal". |

|

A corner of the factory. |

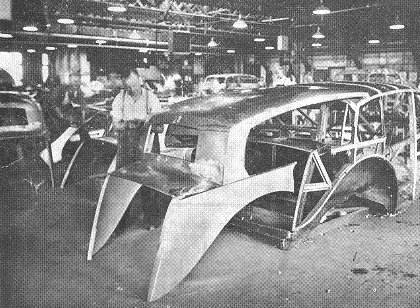

| At work on Triumph Tonneau car

bodies. From the autumn

1947 edition of the staff magazine "Zeal". |

|

|

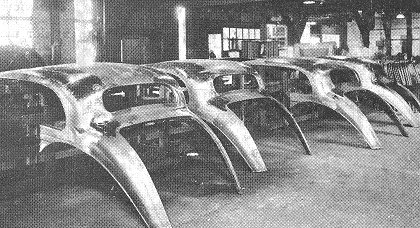

A bank of Armstrong Siddeley

car bodies awaiting despatch.

From the autumn 1947 edition of

the staff magazine "Zeal". |

|

Return to

the

previous page |

|