| Rubery, Owen & Company

Limited, Wrexham |

|

In the 1930s the Steel Equipment Department at the Darlaston

factory under the management of Mr. W. Reeves, and Mr. W.

Gwinnett (who later became Managing Director of Rubery Owen &

Kemsley, Australia), rapidly grew, and larger premises became

essential.

In 1945 after the war, there was a shortage of skilled labour,

and so the firm decided to take advantage of a Government scheme

to disperse work from industrial areas to designated development

areas. One of the development areas was Wrexham, well-known to

the Owen family, and birthplace of the late A. E. Owen.

The opportunity arose to acquire the Whitegate Factory, which had

been built by the Rubery Owen Structural Department for the

Ministry of Aircraft Production. The factory was purchased by Rubery Owen in mid 1946, but at that time was leased by the

Ministry of Aircraft Production to the Ministry of Works, as an

overflow factory for the manufacture of frames for the

pre-fabricated Arcon houses, the standard Ministry of Works

prefabricated design, to alleviate the housing shortage after the

war.

In December 1946 a few capstan machines were transferred from

Darlaston to form the nucleus of the Aviation Department, to

produce bright bolts and studs. |

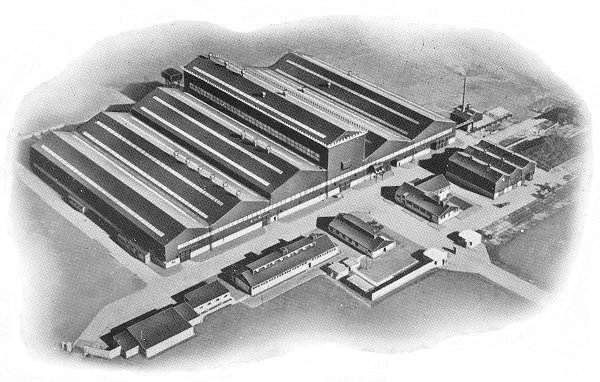

An aerial view of the Whitegate Factory. From the summer 1950 edition of

the staff magazine "Goodwill". |

|

Early in 1947, the Leabank Chair

Department began to transfer production to the Wrexham

site. Within six months from the completion of the

transfer, production had doubled. This was quite an

achievement considering that all of the local production

staff had to be trained in the kind of work they had never

previously experienced.

Around the middle of 1947 the

production of Arcon frames at the factory had ended, and

transfer of the Steel Equipment Department to Wrexham

began. When this had been completed in January 1948, the

factory began to function as an individual unit. |

|

Another view of the factory. |

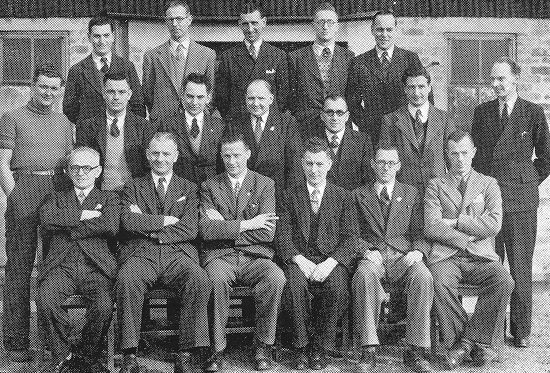

The ex-Darlaston people who

formed the nucleus of the new company.

Back row left to right: C. Heming, J. James, I.

Hall. H. Hughes, and C. Dukes.

Middle row left to right: F. Boynton, F. Bale, R. A.

Griffiths, H. Case, E. Abnett,

G. Coughlin, and E. Blakemore.

Front row left to right: W. H. Clayfield, G.

Dawkins, D. E. Newcombe, R. G. Broome,

S. Shinton, and S. Cook. From the April 1947 edition

of the staff magazine "Goodwill". |

Mr. G. Anderson, Manager of Rubery,

Owen and Company Limited, Wrexham. From the April 1947

edition of the staff magazine "Goodwill". |

By the end of June the firm’s expanding export

market had exceeded the targets announced by the Board

of Trade by over thirty percent.

The department became known as Wrexham Metal

Equipment Department, and produced all kinds of office

furniture, and industrial storage products, including

stores shelving and racking, lockers, cupboards,

pallets, stillages, cow sheds for Australia, and shell

carriers for the Admiralty. |

|

Some of the firm's adjustable

shelving, lockers, and cabinets. |

| The Wrexham factory had been run from Darlaston as a

separate department until 1st April, 1973 when it was

formed into a new company, Rubery Owen (Wrexham)

Limited, and transferred to the Domestic Equipment

sub-group. |

A cow shed for Australia. From the

April 1947 edition of the staff magazine "Goodwill". |

The Assembly Shop. From the April

1947 edition of the staff magazine "Goodwill". |

A sports ground was built, which came under the

control of the Social and Welfare Committee.

Activities included football, cricket, bowls, darts,

netball, tennis, angling, and shooting. The football

club was managed by Mr. H. Hughes, ably assisted by Mr.

C. Jukes, both ex-Darlaston men.

The works football team had great success in the

Third Division of the Welsh National League.

The indoor sports were held in Wrexham Drill Hall

which allowed employees to use the hall's billiards,

table tennis, and darts facilities. |

|

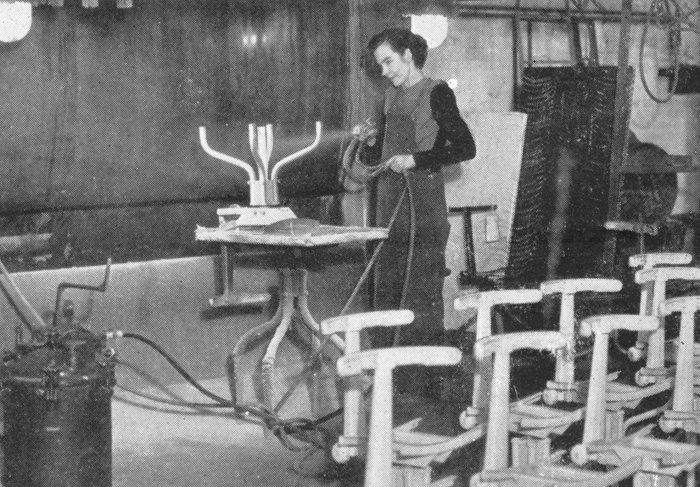

Spraying parts for office

chairs. |

|

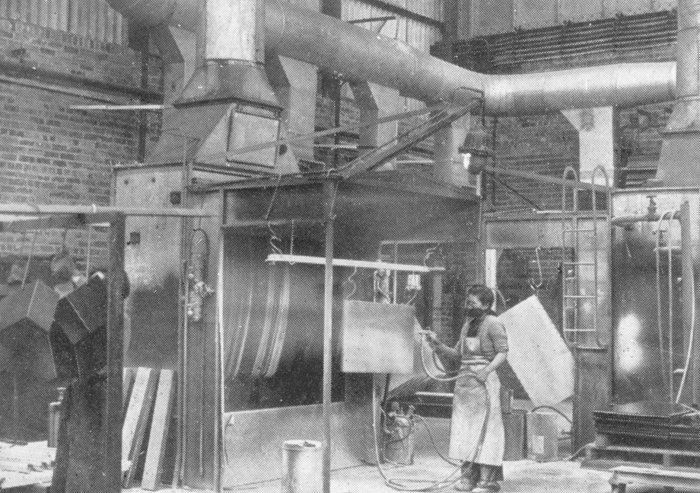

Spraying sheet metal parts. |

|

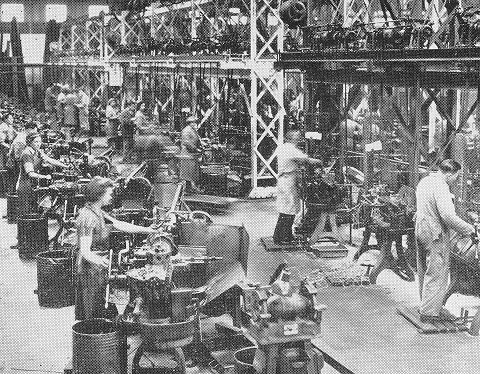

Assembling sheet metal

products. |

|

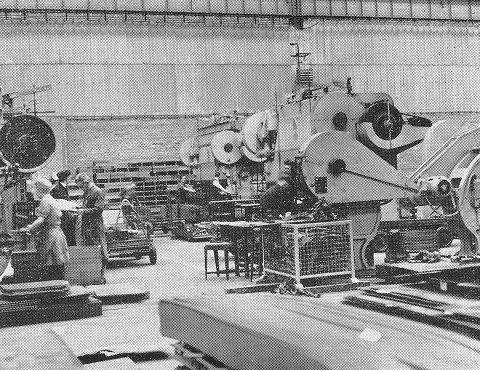

Part of the sheet metal shop,

with a guillotine and presses. |

| Making Leabank chair

upholstery.

From the April 1947 edition of the

staff magazine "Goodwill". |

|

|

A corner of the Toolroom.

From the April 1947 edition of the

staff magazine "Goodwill". |

| Part of the Press Shop.

From the April 1947 edition of the

staff magazine "Goodwill". |

|

|

The Aviation Department.

From the April 1947 edition of the

staff magazine "Goodwill". |

|

Return to

the

previous page |

|